PET heat-sealing film coating antifogging agent, PET antifogging easy-to-uncover film and preparation method and application thereof

A technology of heat-sealing film and anti-fogging agent, which can be used in coatings, polyurea/polyurethane coatings, etc., and can solve the problems of difficult opening, large heat-sealing, and non-compliance with environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

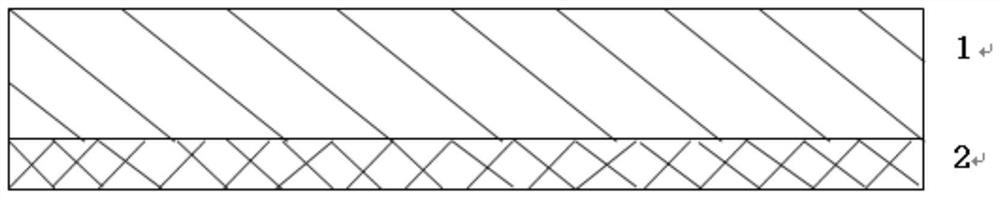

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing a PET anti-fog and easy-to-remove film, comprising the following steps:

[0045] Unwind the BOPET single-sided heat-sealable film, corona-treat the heat-sealed surface, then apply the PET heat-sealable film described in the above technical solution, apply anti-fogging agent, dry, detect and rewind to obtain PET anti-fog easy Peel off the film.

[0046] The method provided by the present invention is simple and cost-effective, and the antifogging agent can be directly coated on the heat cover of the BOPET single-sided heat-sealing film; Fogs have good cold and hot anti-fog effects, and are more cost-effective.

[0047] In the present invention, the BOPET single-sided heat-sealed film roll is preferably unfolded under a tension of 50-120N. The film roll runs forward continuously through a plurality of guide rollers, and uses two identical stations to work alternately, using automatic splicing and fast Change the film to achi...

Embodiment 1

[0061] BOPET heat-sealing film is formed by three-layer melt co-extrusion, and the three-layer material is divided into upper surface layer, core layer and heat-sealing layer;

[0062] The upper surface layer is also called anti-adhesive layer, which is made of the following raw materials by weight percentage: 42% of bright polyester chips, 8% of smooth masterbatch, and 50% of anti-adhesive masterbatch;

[0063] The raw material of the core layer is bright polyester chips;

[0064] 25% terephthalic acid; 45% ethylene glycol; 25% isophthalic acid; 2.5% triethyl phosphate heat stabilizer; PC-64 phosphorus titanium chelate catalyst 2.0% and anti-blocking agent SiO 2 0.5% mixed to obtain a heat seal mix.

[0065] Dry the anti-adhesive layer material, core layer material and heat-sealing mixture separately, three-layer melt co-extrusion, cast casting, longitudinal stretching, transverse stretching, traction winding, slitting, and obtain BOPET single-sided thermal Sealing film, w...

Embodiment 2

[0071] The difference with embodiment 1 is:

[0072] Acrylic acid graft modified polyester polyol 11%; hexamethylene diisocyanate 3.6%; acetone 5%; dimethylol propionic acid 3.2%; 3-allyloxy-2-hydroxy-1-propanesulfonate Sodium acid salt 3.0%; Maleic anhydride 2.0%; Isopropanol 3.2%; Ethylene glycol 3.5%; Sodium persulfate initiator 1.0%; Dibutyltin dilaurate catalyst 1.0%; %; palm wax anti-sticking agent 2.0%; SiO 2 1.0% anti-blocking agent and 60% soft water are mixed to obtain an anti-fogging agent.

[0073] The present invention adopts haze meter and gloss meter to test the haze and the glossiness of the PET anti-fog easy-to-remove film prepared in Example 2; the haze of the PET anti-fog easy-to-remove film prepared in Example 1 is 1.25%, and the gloss is 98.9GU.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com