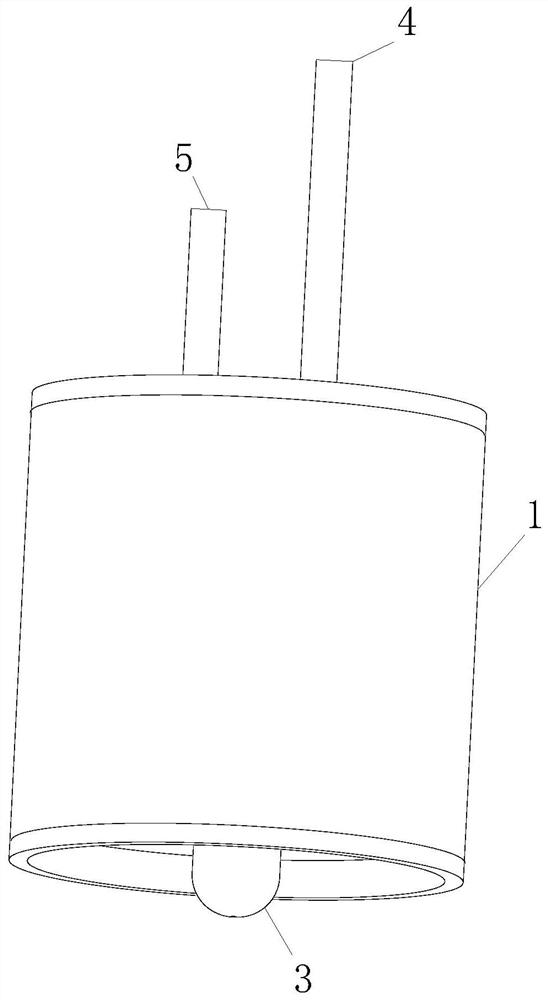

Solid aluminum electrolytic capacitor

An aluminum electrolytic capacitor, solid-state technology, applied in the field of capacitors, can solve problems such as affecting work efficiency, increasing internal pressure, capacitor heating, etc., to achieve the effects of optimizing work performance, protecting working conditions, and reducing working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

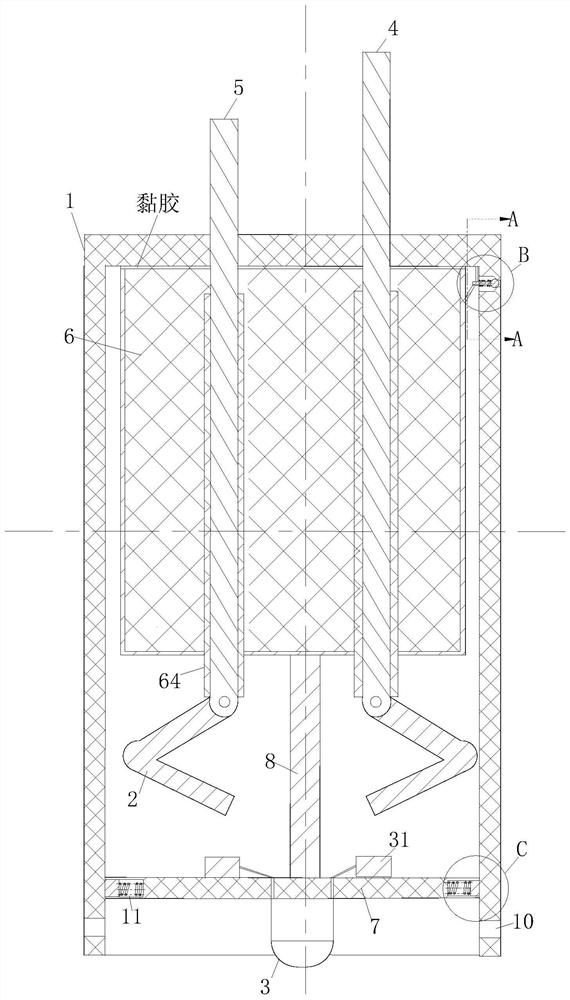

[0033] As an embodiment of the present invention, the rubber pad 7 seals the other end of the housing 1; the housing 1 is filled with nitrogen; during operation, the present invention fills the housing 1 with nitrogen, and then passes the rubber pad 7. Seal the other end of the shell 1 to form a sealed environment inside the shell 1. The filled nitrogen can effectively reduce the working temperature of the solid aluminum electrolytic capacitor and maintain the stability inside the solid aluminum electrolytic capacitor. When the internal heat is generated, the heat is transferred to the folding rod 2 to achieve a heat conduction effect so that the folding rod 2 remains in a contracted state and optimizes the working performance of the solid aluminum electrolytic capacitor.

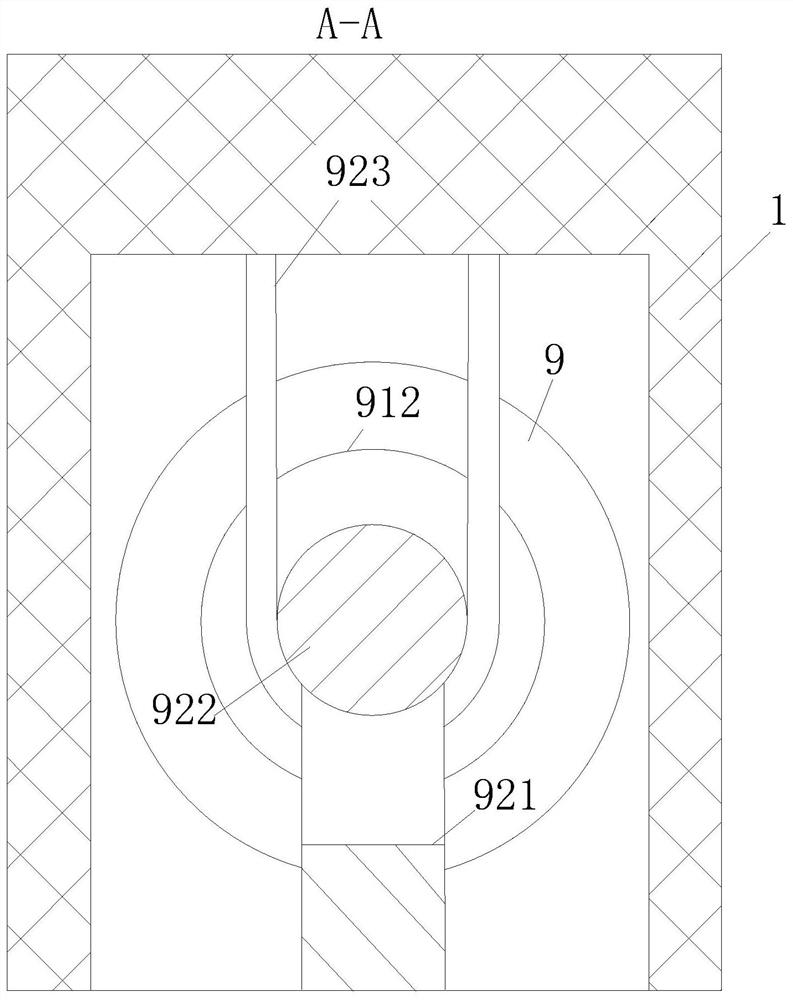

[0034] As an embodiment of the present invention, a stepped hole 9 is provided on the outer wall of the housing 1; a check valve 91 is installed in the stepped hole 9; the nitrogen can enter the interior of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com