Vascularized bone bionic multifunctional tissue engineering scaffold with anti-inflammatory effect and preparation method thereof

A technology of tissue engineering scaffold and anti-inflammatory effect, applied in tissue regeneration, pharmaceutical formula, coating, etc., can solve the problems of prolonging the healing time of bone defects, and achieve the effect of promoting vascularization, anti-inflammatory preparation method, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

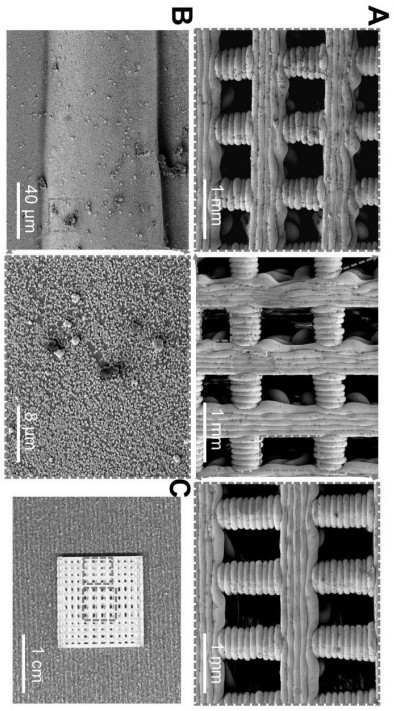

[0055] (1) The cortical and cancellous bone structure that simulates natural bone is modeled by AutoCAD, 3DSMAX and other modeling software to obtain a three-dimensional model.

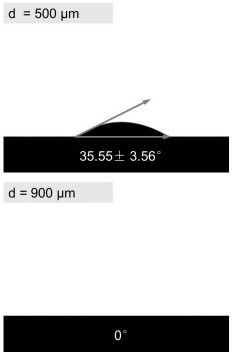

[0056] (2) Using FDM technology, biomimetic PLA scaffolds with gradient pore sizes of 500 μm and 900 μm were prepared by 3D printers. (3) At room temperature, the PLA scaffolds were soaked in ammonia solution with a pH value of 12 and stirred at a speed of 180 rpm for 4 h, and then the alkali-treated PLA scaffolds were soaked in a concentration of 1% ( W / V ) in the HA ethanol solution at 180 rpm for 1.5 h, then placed the PLA scaffold in absolute ethanol and sonicated for 3 min to remove excess HA on the surface of the scaffold, and finally air-dried at room temperature.

[0057] (4) Weigh 10 g of gelatin and dissolve it in 100 mL of PBS solution, and stir for 1 h in a warm bath at 45 °C until completely dissolved. Slowly add 8 mL of MA into the gelatin solution dropwise, and after stirring for 2 h, ...

Embodiment 2

[0063](1) The cortical and cancellous bone structure that simulates natural bone is modeled by AutoCAD, 3DSMAX and other modeling software to obtain a three-dimensional model.

[0064] (2) Using FDM technology, biomimetic PLA scaffolds with gradient pore sizes of 400 μm and 800 μm were prepared by 3D printers.

[0065] (3) At room temperature, soak the PLA scaffold in an ammonia solution with a pH value of 12 and stir it at a speed of 175 rpm for 4 hours, and then soak the alkali-treated PLA scaffold in a concentration of 1% ( W / V ) in the HA ethanol solution at 180 rpm for 2 h, then placed the PLA scaffold in absolute ethanol and sonicated for 3 min to remove excess HA on the surface of the scaffold, and finally air-dried at room temperature.

[0066] (4) Weigh 10 g of gelatin and dissolve it in 100 mL of PBS solution, and stir in a warm bath at 50 °C for 1 h until completely dissolved. 8 mL of MA was slowly added dropwise to the gelatin solution, and after stirring for 1.5 ...

Embodiment 3

[0072] (1) The cortical and cancellous bone structure that simulates natural bone is modeled by AutoCAD, 3DSMAX and other modeling software to obtain a three-dimensional model.

[0073] (2) Using FDM technology, biomimetic PLA scaffolds with gradient pore sizes of 450 μm and 850 μm were prepared by 3D printers.

[0074] (3) At room temperature, soak the PLA scaffold in an ammonia solution with a pH value of 12 and stir at a speed of 180 rpm for 4 hours, and then soak the PLA scaffold after alkali treatment in a concentration of 1% ( W / V ) in the HA ethanol solution at 180 rpm for 1.5 h, then placed the PLA scaffold in absolute ethanol and ultrasonicated for 3 min to remove excess HA on the surface of the scaffold, and finally air-dried at room temperature.

[0075] (4) Weigh 10 g of gelatin and dissolve it in 100 mL of PBS solution, and stir for 1 h in a warm bath at 45 °C until completely dissolved. Slowly add 8 mL of MA into the gelatin solution dropwise, and after stirring...

PUM

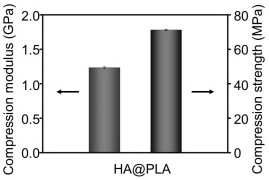

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com