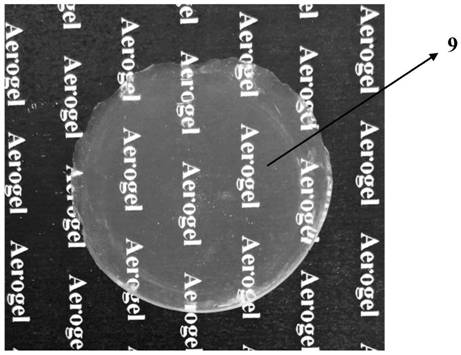

Light silicon dioxide aerogel with ultrahigh transparency and ultralow haze as well as preparation method and application of light silicon dioxide aerogel

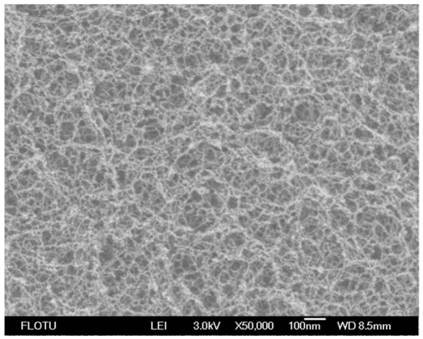

A light-weight silica and transparency technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem of not paying enough attention to the light transmission of airgel, achieve precise control of the reaction environment, and avoid heavy Poor performance and stability, weak scattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In a first aspect, the present invention provides a method for preparing a lightweight silica aerogel with ultra-high transparency and ultra-low haze, said method comprising the steps of:

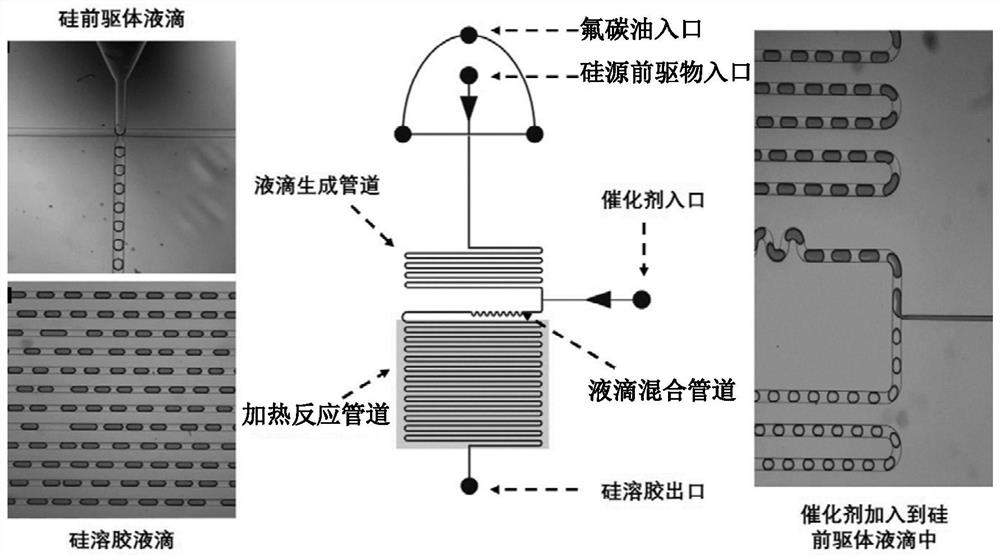

[0034] (1) Microreactor device (also denoted as microfluidic droplet microreactor device) is provided: the microreactor device includes a PDMS microfluidic chip and an ITO electrode connected to the PDMS microfluidic chip; The PDMS microfluidic chip includes a first region, a second region, a third region, a fourth region and a fifth region connected in sequence, and the ITO electrode is connected to the fourth region of the PDMS microfluidic chip; In the present invention, along with the flow direction of the silicon source precursor (also referred to as the silicon source precursor phase) and the fluorocarbon oil (also referred to as the fluorocarbon oil phase), the first region, the second region, the third region, The fourth area and the fifth area, in the present invention, the ...

Embodiment 1

[0065] ①Provide a microreactor device; weigh 15.2g (0.1mol) of methyl orthosilicate, 7.2g (0.4mol) of water and 64g (2mol) of methanol, mix well as the silicon source precursor phase, and use a syringe to extract the silicon source precursor Phase 10mL, and at the inlet of the silicon source precursor in the microreactor device, introduce the silicon source precursor phase through the injection side channel. Use a syringe to extract 50 mL of perfluorocarbon oil (fluorocarbon oil) as the oil phase, and introduce the perfluorocarbon oil through the injection side channel at the inlet of the fluorocarbon oil in the microreactor device. Utilize a syringe to extract 5 mL of dilute hydrochloric acid (catalyst) with a concentration of 0.1 mol / L, and introduce the dilute hydrochloric acid through the injection side channel at the catalyst inlet in the microreactor device.

[0066] ②The first area of the PDMS microfluidic chip included in the microreactor device includes the inlet of...

Embodiment 2

[0075] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0076] In step ①, weigh 15.2g (0.1mol) of methyl orthosilicate, 3.6g (0.2mol) of water and 38.4g (1.2mol) of methanol (the molar ratio of silicon source, water and methanol is 1:2:12 ), mixed uniformly as the silicon source precursor phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com