Device and method for continuously removing cations in water for hydrogen conductivity measurement

A hydrogen conductivity and water removal technology, which is applied in the direction of measuring devices, chemical instruments and methods, and the preparation of test samples, can solve problems affecting data accuracy, inaccurate display of hydrogen conductivity data, and affecting operational safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

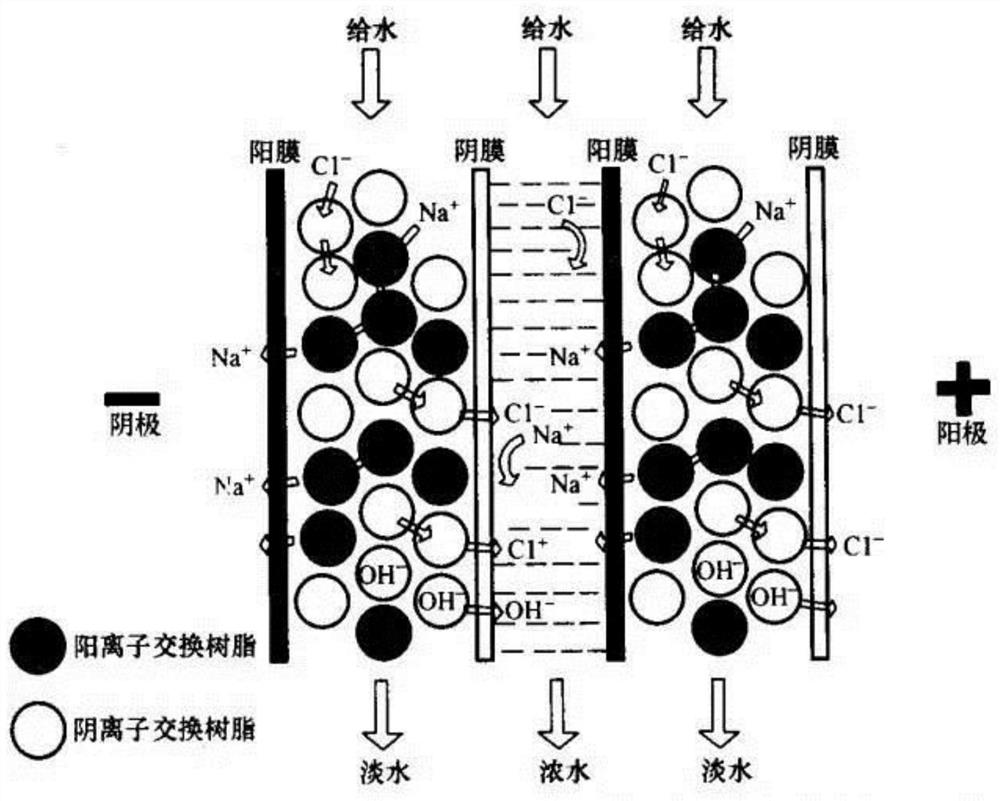

Method used

Image

Examples

Embodiment 1

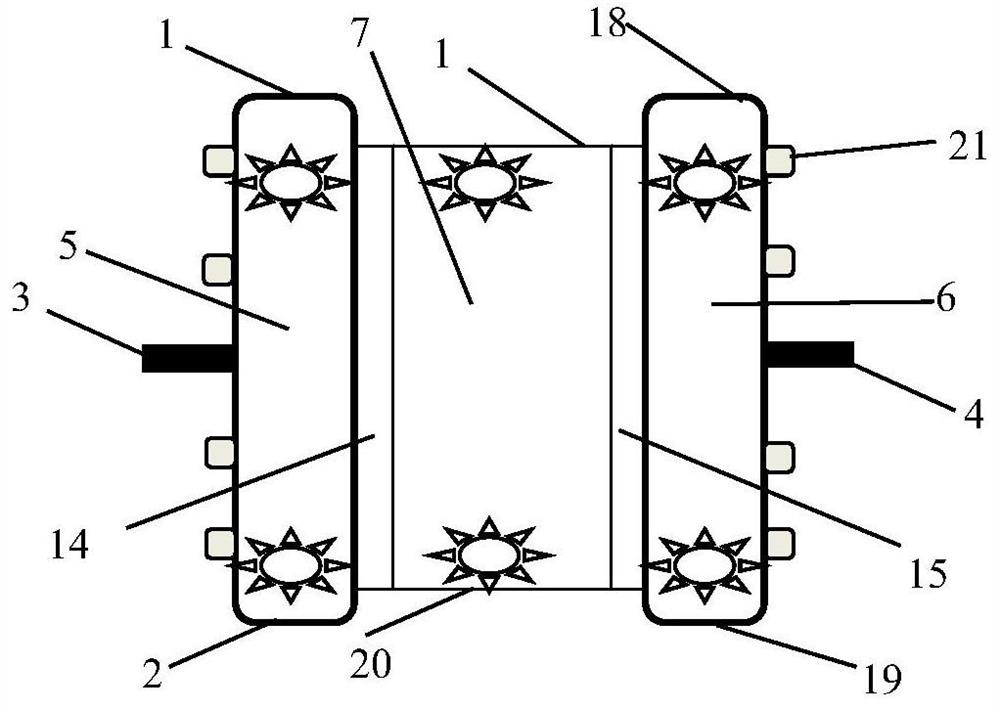

[0051] Such as image 3 As shown, a device for continuously removing cations in water for hydrogen conductivity measurement includes: conductivity meter 8, pH meter 9, pure water tank 10, ammonia-containing water tank 11, electric deamination device 12, power supply 13, power Water pump 16 and flow meter 17;

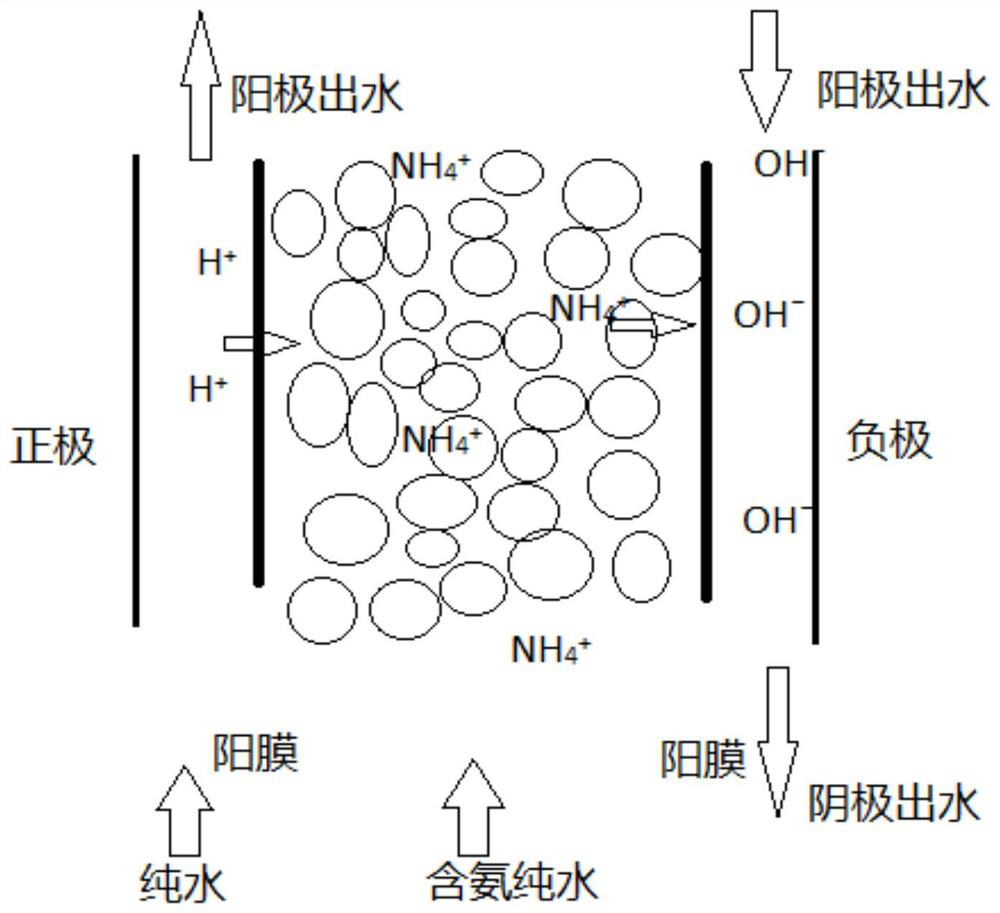

[0052] Wherein the electric deamination device 12 comprises an ammonia removal compartment 7, a positive electrode chamber 5 and a negative electrode chamber 6; the positive electrode chamber 5 and the negative electrode chamber 6 are respectively located on the left and right sides of the electric deamination device 12, between the positive electrode chamber 5 and the ammonia removal compartment 7 A positive electrode chamber water distribution plate 14 is provided, and a negative electrode chamber water distribution plate 15 is provided between the negative electrode chamber 6 and the ammonia removal compartment 7; the positive electrode chamber 5 is provided with posi...

Embodiment 2

[0054] On the basis of Example 1, it is judged as Figure 4 The removal effect of ammonia after the continuous removal of cations in water for hydrogen conductivity measurement is shown:

[0055] 1. The specification of the ammonia removal equipment in this test is the CEDI-200 model developed by Hangzhou Water Treatment Technology Research and Development Center Co., Ltd. The strong acid ion resin is selected from Zhengguang Company 001×7 strong acid cation resin, and the packing density of this equipment is 1.25g / m . Device initialization, the initialization process is as follows:

[0056] Step 1. Configure about 1% NaOH solution, flow into the ammonia removal compartment, and soak for 12 hours;

[0057] Step 2. Use pure water to rinse the 1% NaOH solution in the equipment until the conductivity is less than 0.3μS / cm;

[0058] Step 3. Configure about 1% HCl solution, flow into the ammonia removal compartment, and soak for 12 hours;

[0059] Step 4. Use pure water to rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com