Desulfurization wastewater concentration and zero discharge treatment process based on flue gas evaporation

A desulfurization wastewater and treatment process technology, applied in the field of treatment process, desulfurization wastewater concentration and zero discharge treatment process, can solve the problem of high investment cost and operating cost per ton of water, long water retention time of clarification device, equipment size and floor space It can reduce system investment and maintenance costs, improve flexibility and stability, and save system investment and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0032] Example.

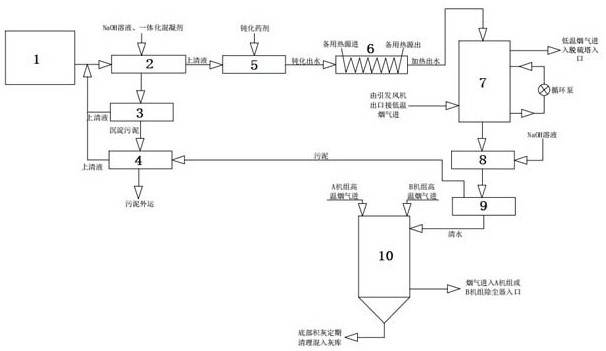

[0033] see figure 1 The desulfurization wastewater concentration and zero discharge treatment process based on flue gas evaporation in this embodiment includes a desulfurization wastewater buffer pool 1, an integrated coagulation and clarification device 2, a sludge concentration tank 3, a sludge dehydration device 4, a passivation reaction device 5, Backup heat source heating device 6, low-temperature flue gas evaporation and concentration device 7, neutralization tank 8, precision filter device 9 and bypass flue evaporation and drying device 10; desulfurization (high salt) wastewater buffer tank 1 and integrated coagulation and clarification device 2 Connection, the integrated coagulation and cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com