Degradable lignin-based composite agricultural mulching film and preparation method thereof

An agricultural mulch, lignin-based technology, applied in the directions of botanical equipment and methods, applications, plant protection covers, etc., can solve problems such as poor mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

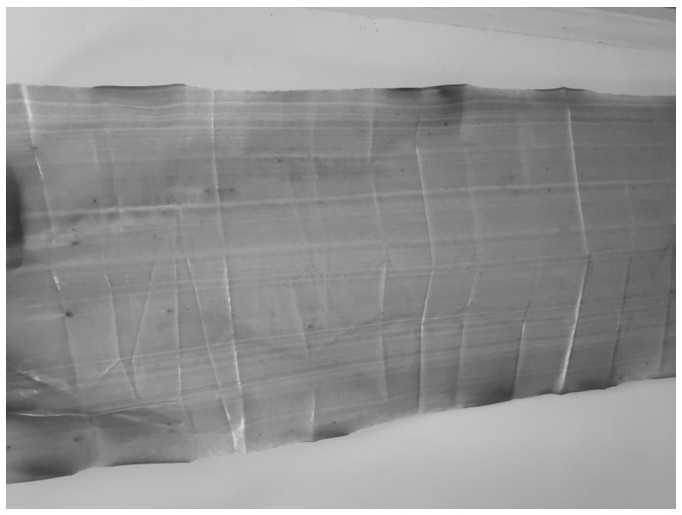

Image

Examples

preparation example Construction

[0034] Preparation of modified lignin:

[0035] ①Maleic anhydride modified lignin: under the condition of a concentration of 2mol / L sodium hydroxide solution, add 10g of lignin and 10g of maleic anhydride, react in an oil bath at 50°C for 7 hours, add 2mol / L hydrochloric acid to adjust the pH= 2 was precipitated, precipitated by centrifugation, washed 6 times with water, and freeze-dried at -20°C for 48 hours.

[0036] ②Epichlorohydrin modified lignin: under the condition of 2mol / L sodium hydroxide solution, add 10g lignin and 5g epichlorohydrin, react in an oil bath at 70°C for 6 hours, centrifuge to precipitate after the reaction, wash with water After 6 times, freeze-dry at -20°C for 48h.

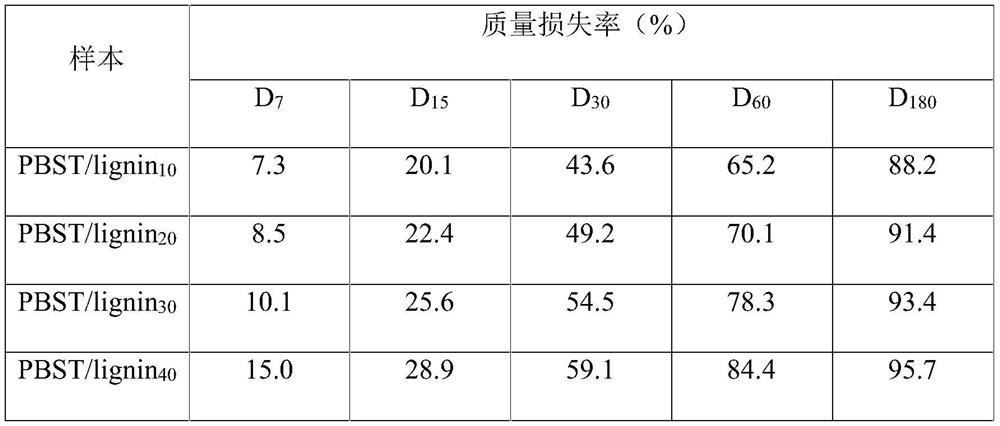

Embodiment 1

[0038] 1) Pretreatment of raw materials: according to the weight fraction, put 90 parts of raw material PBST and 10 parts of enzymatic lignin in a blast drying oven, and dry at 50-70°C to remove water;

[0039] 2) Pre-mixing of raw materials: 10 parts of enzymatic lignin, 90 parts of PBST, 1 part of erucamide opening agent, 1 part of KH560 coupling agent, 1 part of stearic acid dispersant, dioctyl phthalate plasticizer 1 part, put into the high-speed mixer together, and carry out the mixing operation for 20 minutes at the speed of 2000r / min to obtain the premix;

[0040]3) Extrusion granulation treatment: the premix is added in the twin-screw reaction extruder, the screw reaction extruder is a co-rotating twin-screw extruder, the length-to-diameter ratio of the screw is 25:1, the screw speed is 50rpm, and the temperature in each zone Controlled at: 110°C in zone 1, 120°C in zone 2, 130°C in zone 3, 130°C in zone 4, 130°C in zone 5, 120°C in zone 6, 110°C in zone 7, through t...

Embodiment 2

[0043] 1) Pretreatment of raw materials: according to the weight fraction, put 80 parts of raw materials PBST and 20 parts of alkali lignin in a blast drying oven, and dry at 50-70 ° C to remove water;

[0044] 2) Pre-mixing of raw materials: 20 parts of alkali lignin, 80 parts of PBST, 1 part of erucamide opening agent, 1 part of KH560 coupling agent, 1 part of stearic acid dispersant, dioctyl phthalate plasticizer 1 part, put into the high-speed mixer together, and carry out the mixing operation for 20 minutes at the speed of 2000r / min to obtain the premix;

[0045] 3) Extrusion granulation treatment: the premix is added in the twin-screw reaction extruder, the screw reaction extruder is a co-rotating twin-screw extruder, the length-to-diameter ratio of the screw is 25:1, the screw speed is 50rpm, and the temperature in each zone Controlled at: 110°C in zone 1, 120°C in zone 2, 130°C in zone 3, 130°C in zone 4, 130°C in zone 5, 120°C in zone 6, 110°C in zone 7, through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com