Preparation method and product of amorphous nanocrystalline tape with insulating coating

An amorphous nanocrystalline and insulating coating technology, which can be used in coatings, devices for coating liquids on surfaces, special surfaces, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Mix 20 ml of TEOS (tetraethoxysilane) and 100 ml of anhydrous ethanol, slowly add 1 ml of deionized water, adjust the pH to 3-4 with 5% hydrochloric acid, maintain electric stirring at 60°C for 4 hours, and then adjust with 10% ammonia water The pH value reaches 8-10, electric stirring for 2-4 hours and ultrasonic dispersion for 30-60 minutes. During the stirring process, anhydrous ethanol is supplemented to maintain a stable concentration. Finally, it is diluted to 1 liter with deionized water to prepare a film-forming agent sol.

[0051] 1 ml of butyl silicate was added to 400 ml of deionized water and mechanically stirred for 0.5 hours, and 0.2 ml of sodium lauryl sulfate, 1 ml of 5% carboxyethyl cellulose, 1.5 g of sodium hexametaphosphate, 30% nanohydrogen 30 ml of the magnesium oxide suspension was adjusted to pH 8.5 with 10% ammonia water; the film-forming agent sol was added to mix, and the coating solution was fully stirred for 2 hours.

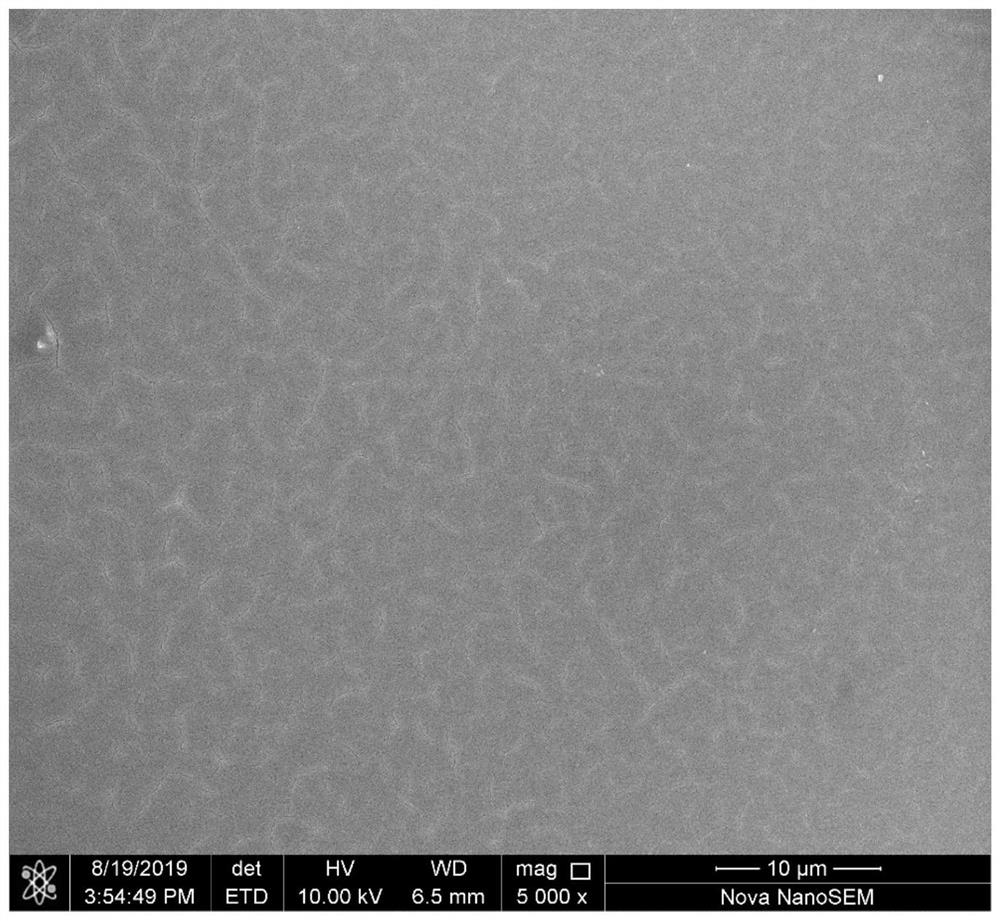

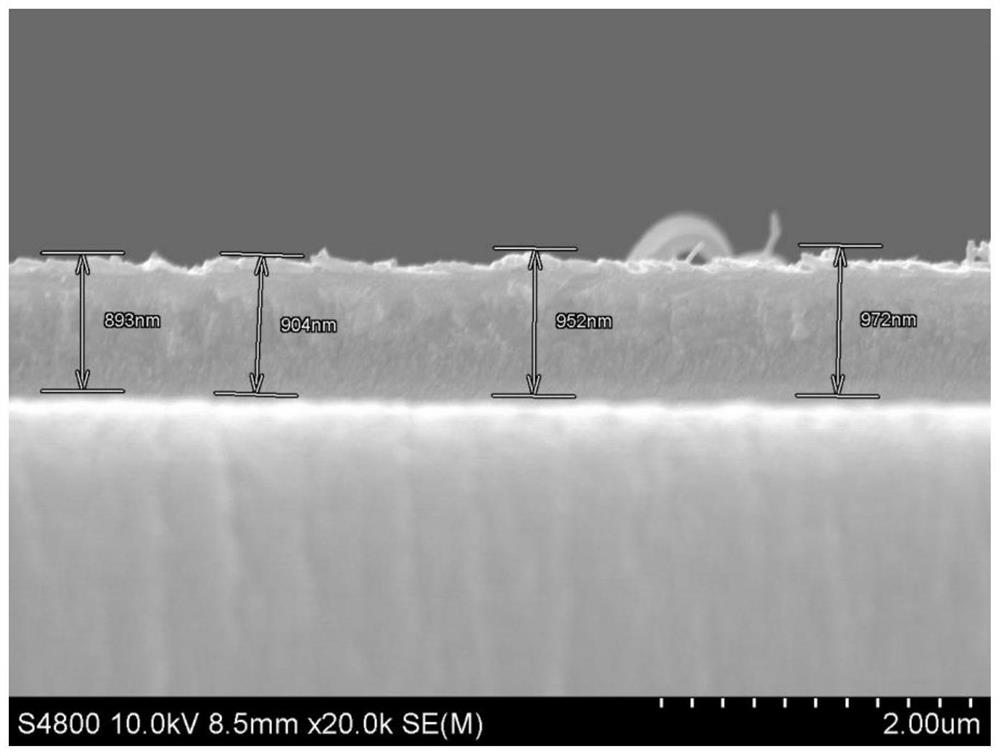

[0052] Use coating equ...

Embodiment 2

[0054] Mix 120 ml of TEOS (tetraethoxysilane) and 780 ml of anhydrous ethanol, add 2 ml of deionized water dropwise, adjust the pH to 3-4 with 5% hydrochloric acid, keep the water bath at 40 °C for 2 hours with electric stirring, and then add 10% ammonia water Adjust the pH value to 8-10, stir electrically for 2 hours and ultrasonically disperse for 60 minutes. During the stirring process, add anhydrous ethanol to maintain a stable concentration, and finally dilute to 1 liter with deionized water to prepare a film-forming agent sol.

[0055] 1 ml of butyl acetate was added to 100 ml of deionized water and mechanically stirred for 0.5 hours, and 0.5 ml of 6503 surfactant and 6 g of sodium hexametaphosphate were added successively, and the pH value was adjusted to 10 with 10% ammonia water; slowly added with a dropping funnel The film-forming agent sol was fully stirred for 2 hours to obtain a coating liquid.

[0056] Use coating equipment to coat the coating liquid on the amorp...

Embodiment 3

[0058] Add 7 grams of modulus 3 water glass to 100 ml of 70°C water, stir well, add 50 ml of 30% nano-alumina ethanol suspension, ultrasonically disperse for 30 minutes, and dilute to 500 ml with deionized water to prepare a pre-sol solution.

[0059] 0.8 g of sodium methylsilicate was added to 500 ml of deionized water and mechanically stirred for 0.5 hours, and 0.2 ml of sodium dodecylbenzenesulfonate, 1 ml of 5% carboxymethyl propyl cellulose, and 3 g of sodium hexametaphosphate were added in sequence. , adjust the pH value to 10 with 10% ammonia water; slowly pour the sol pre-preparation solution, and fully stir for 2 hours to obtain the coating solution.

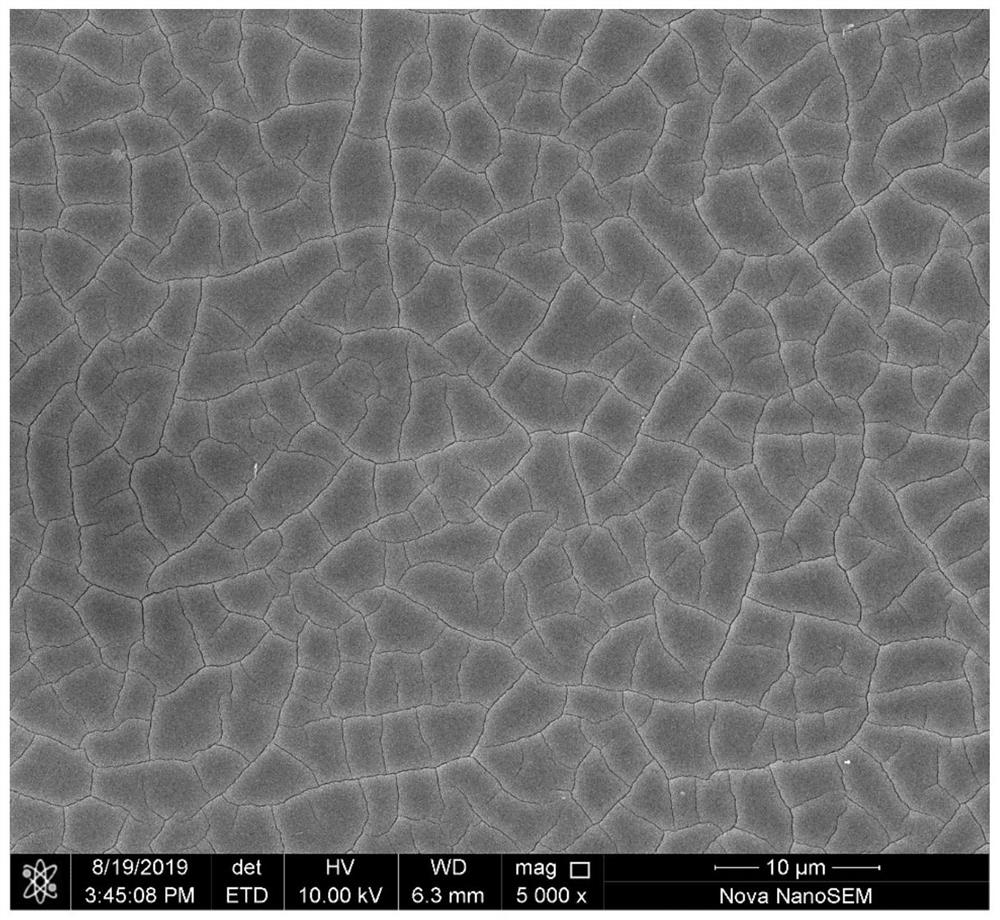

[0060] Use coating equipment to coat the coating liquid on the amorphous nanocrystalline tape, adopt the coating method of dip coating, the complete immersion stroke is 0.6 m, the dip coating speed is 6 m / min, the drying temperature is 280 ℃, and the heat treatment is 580 ℃ 2 hours. The prepared insulating coating is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com