A food-grade one-component deketoxime type silicone adhesive and preparation method thereof

A silicone adhesive, one-component technology, used in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of poor mechanical properties, affect the performance and quality of automatic dishwashers, and cannot achieve organic The silicone adhesive is resistant to boiling and other problems, and achieves the effects of good mechanical properties, accelerated surface drying speed, and improved construction and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

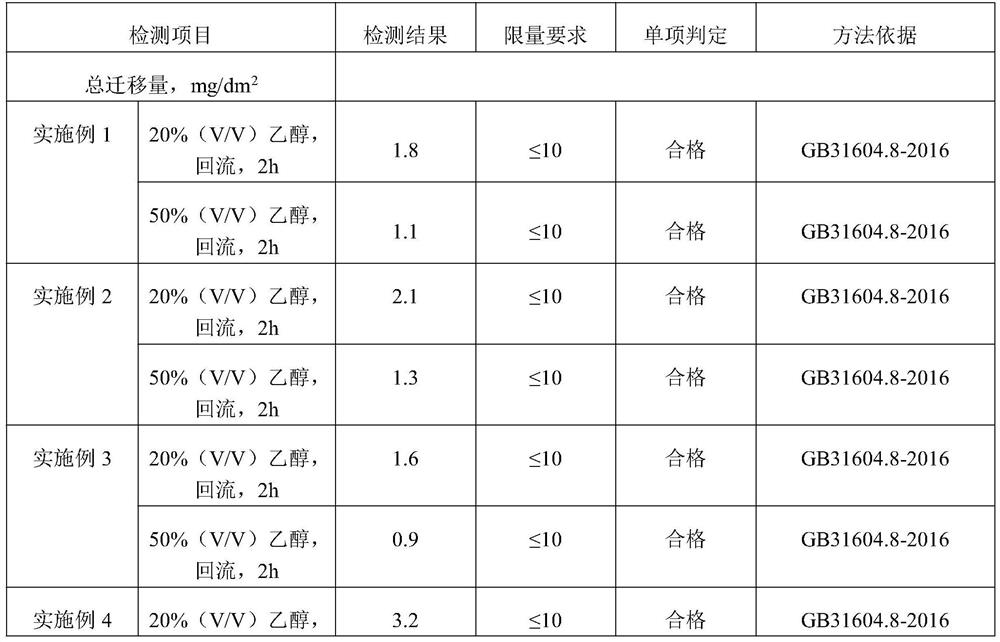

Embodiment 1

[0037] A food-grade one-component deketoxime type silicone adhesive, the preparation method of which is:

[0038] In parts by mass, 350 parts of 107 glue with a viscosity of 20000mPa·s, 350 parts of 107 glue with a viscosity of 50000mPa·s, 70 parts of α, ω-dihydroxypolymethylphenylsiloxane with a viscosity of 50000mPa·s, 80 parts Silicone oil with a viscosity of 1000mPa·s is added to a planetary mixer and stirred under vacuum for 10 to 15 minutes, then 50 parts of methyl tributylketoxime silane and 10 parts of vinyl tributylketoxime silane are added and stirred under vacuum for 15 to 20 minutes, and then 25 parts of TS-530 (the surface has been treated with hexamethyldisiloxane and baked at 105°C for 1 hour), 15 parts of ureidopyrimidinone surface-modified fumed silica, 10 parts of modified fumed silica, first slowly stirred until the second The two fillers are fully infiltrated, then vacuumed and stirred for 40 minutes, then add 900 parts of GZT-2500 (diatomite treated with 1...

Embodiment 2

[0048] A food-grade one-component deketoxime type silicone adhesive, the preparation method of which is:

[0049] In parts by mass, add 700 parts of 107 glue with a viscosity of 20000mPa·s, 70 parts of α, ω-dihydroxypolymethylphenylsiloxane with a viscosity of 50000mPa·s, and 60 parts of silicone oil with a viscosity of 1000mPa·s into a planetary mixer for pumping Stir in vacuum for 10-15 minutes, then add 40 parts of methyl tributylketoxime silane, 8 parts of vinyl tributyl ketoxime silane and stir in vacuum for 15-20 minutes, then add 30 parts of TS-530 (surface treated with hexamethyl di Siloxane treatment and baked at 105°C for 1h), 15 parts of ureidopyrimidinone surface-modified fumed silica, 15 parts of modified fumed silica, first stir slowly until the second filler is fully infiltrated, then vacuumize and speed up Stir for 40min, then add 960 parts of GZT-2500 (diatomaceous earth treated with 1.5% hexadecyltrimethoxysilane, bake at 105°C for 1h), 8 parts of carbon blac...

Embodiment 3

[0052] A food-grade one-component deketoxime type silicone adhesive, the preparation method of which is:

[0053] In parts by mass, add 650 parts of 107 glue with a viscosity of 50000mPa·s, 70 parts of α, ω-dihydroxypolymethylphenylsiloxane with a viscosity of 50000mPa·s, and 110 parts of silicone oil with a viscosity of 1000mPa·s into a planetary mixer for pumping Stir in vacuum for 10-15 minutes, then add 40 parts of methyl tributylketoxime silane, 8 parts of vinyl tributyl ketoxime silane and stir in vacuum for 15-20 minutes, then add 30 parts of TS-530 (surface treated with hexamethyl di Siloxane treatment and baked at 105°C for 1h), 15 parts of ureidopyrimidinone surface-modified fumed silica, 15 parts of modified fumed silica, first stir slowly until the second filler is fully infiltrated, then vacuumize and speed up Stir for 40min, then add 880 parts of GZT-2500 (diatomaceous earth treated with 1.5% hexadecyltrimethoxysilane, bake at 105°C for 1h), 8 parts of carbon bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com