Preparation method of electronic copper-plated oxide high-temperature superconducting material PCCO single crystal

A technology of superconducting materials and oxides, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of difficulty in grasping sample purity, temperature, time, low proportion of single crystal samples, and inability to obtain crystals. Avoid excessive volatilization and wall climbing, high yield and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

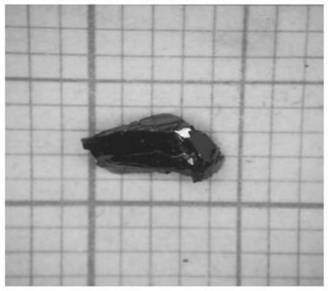

Image

Examples

Embodiment Construction

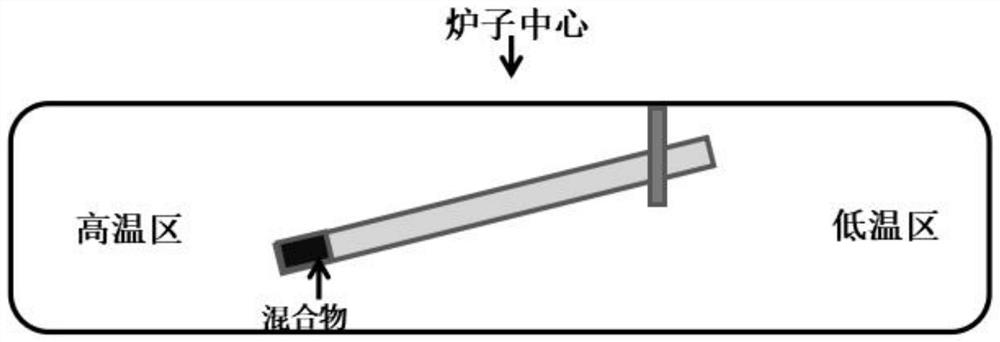

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

[0029] A method for preparing an electron-plated copper oxide high-temperature superconducting material PCCO single crystal, comprising the steps of:

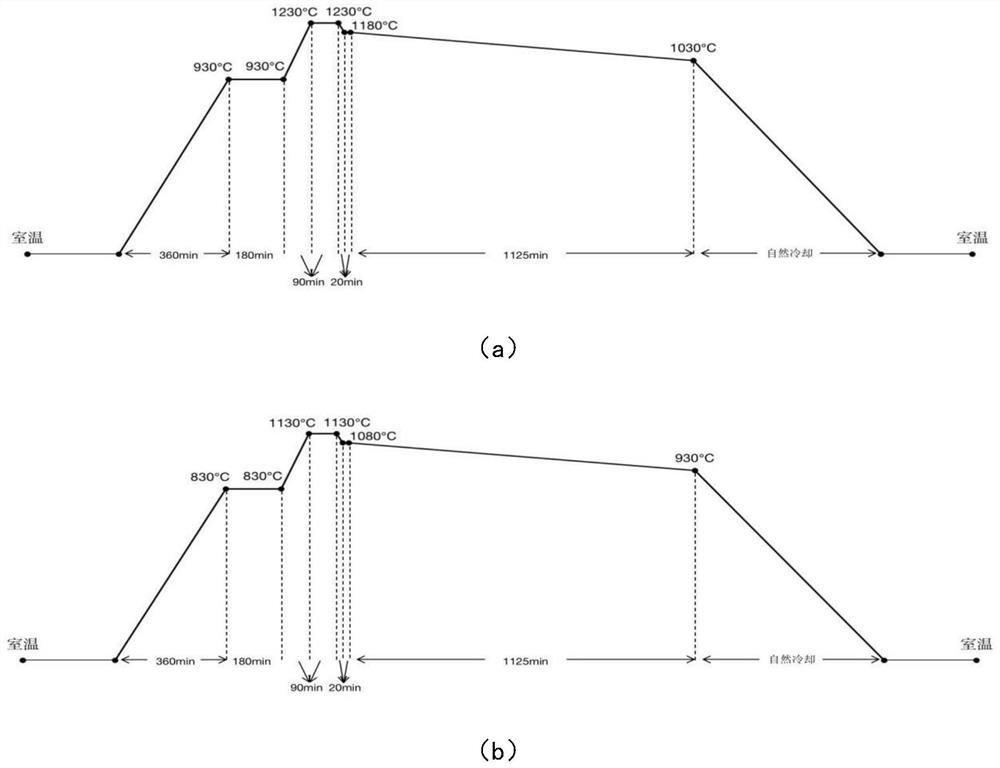

[0030] Step A1: First put Pr 6 o 11 , CeO 2 and CuO, the three initial solid powder compounds, were weighed in the glove box according to the atomic ratio of Pr:Ce:Cu = 1.85:0.15:1, and the mass of each compound required was accurately weighed. Then these three compounds were fully mixed in a mortar, and then pressed into a tablet with a pressure of 4 MPa and a diameter of 12 mm to obtain a disc with a thickness of 2 mm.

[0031] Step A2: Insert the disc into Al 2 o 3 Inside the crucible, Al 2 o 3 Put the crucible into the tube furnace, control the temperature to rise to 930°C, the rise time is 4 hours, and maintain the temperature at 930°C for 20 hours;

[0032] Step A3: Naturally cool down to room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com