Solar cell and electronic device

A technology of solar cells and front electrodes, applied in battery circuit devices, circuits, current collectors, etc., can solve the problems of short battery life of smart glasses, decreased photoelectric conversion efficiency, and inability to meet the power requirements of smart glasses lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

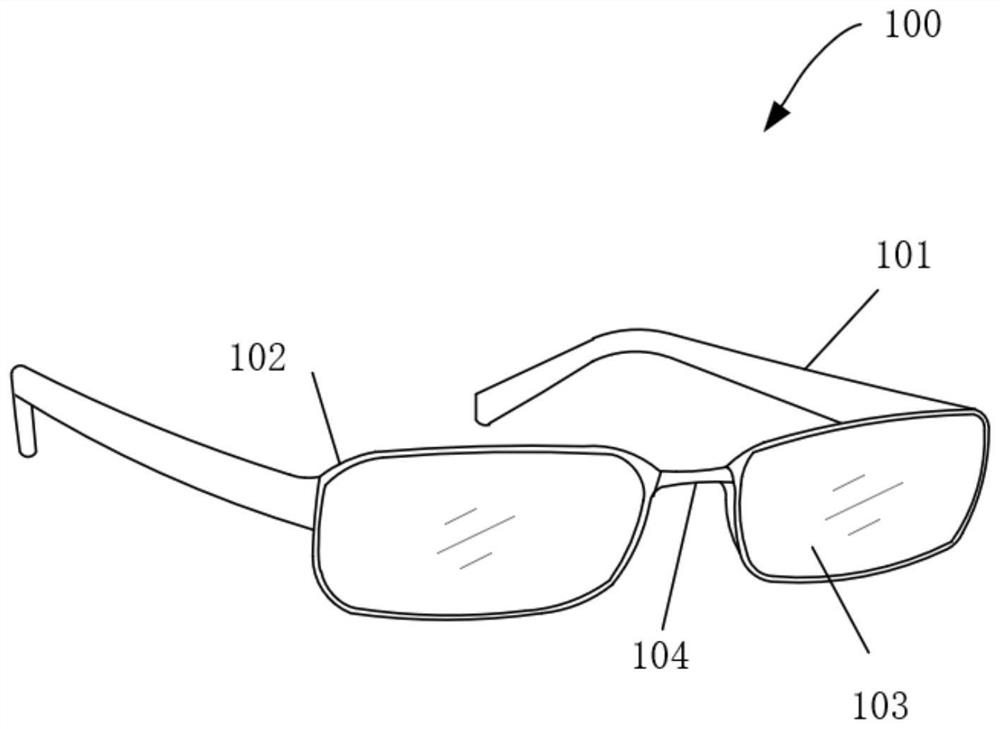

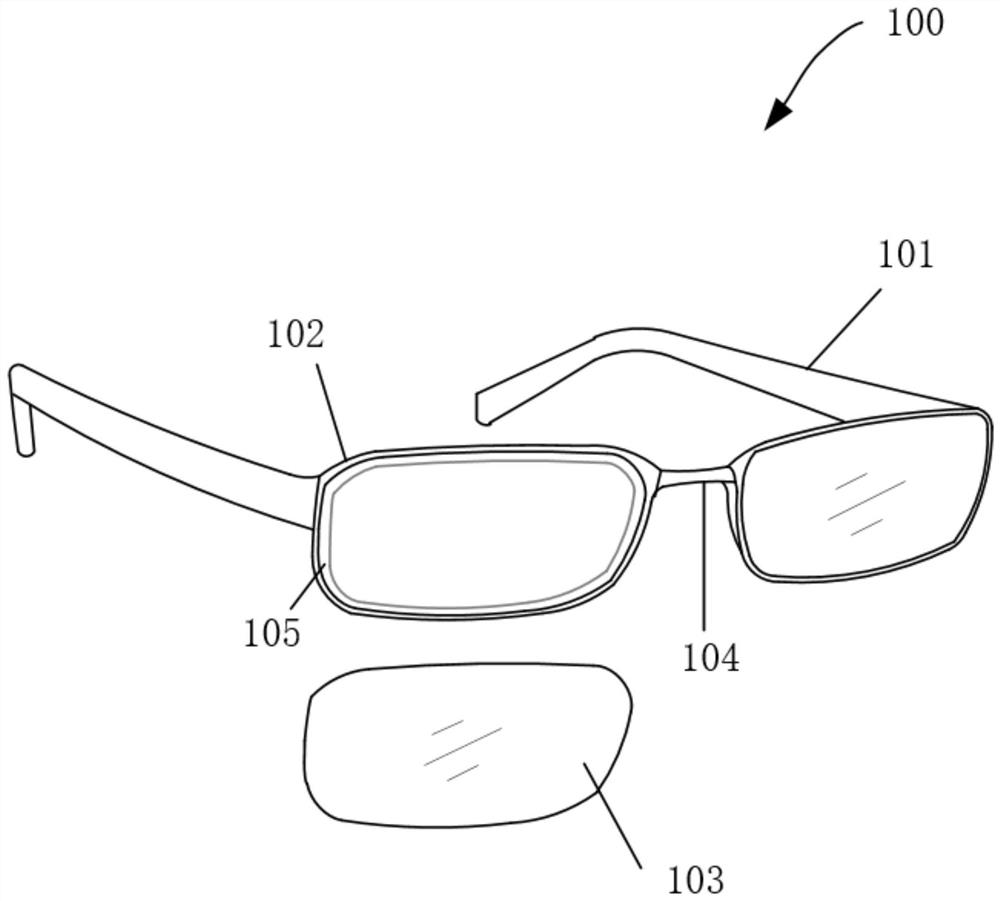

[0097] A kind of smart glasses, including solar battery lens, the structure of solar battery lens can be found in Figure 16 . The solar cell lens includes a lens substrate 10 and a solar cell 20 disposed on the lens substrate 10, and the conductive area A of the front electrode 21 of the solar cell 20 adopts an Ag / Cu composite metal grid layer 202 embedded in a transparent colloid layer 201, wherein, The grid groove width of the metal grid layer 202 is about 3.5 μm, the groove depth is about 3 μm, the silver filling depth in the groove is about 2.3 μm, the copper plating depth is about 1.0 μm, and the metal copper protruding from the surface of the groove is polished, The step after polishing is less than 10nm (ie, the height difference between the upper surface of the metal grid layer 202 and the upper surface of the transparent colloidal layer 201 is less than 10nm), and the groove pattern in the transparent colloidal layer 201 is a regular hexagon with a side length of 85 ...

Embodiment 2

[0099] Compared with Example 1, the only difference is that: the conductive region D of the back electrode is an Al electrode, the thickness of the Al layer is 150nm, and the width Wr is 1mm, and the conductive region C of the back electrode adopts a thin-layer metal / metal oxide composite electrode. Ag / MoO 3 Composite electrode, wherein, Ag thickness 10nm, MoO 3 Thickness 35nm, prepared 30cm 2 The photoelectric conversion efficiency of the large-area device cell is more than 2%.

Embodiment 3

[0101] The structure of the solar cell lens can be found in Figure 17 . Compared with Example 1, the only difference is that: the conductive region D of the back electrode 22 is an Al electrode, the thickness of the Al layer is 110 nm, and the width Wr is 1 mm, and the conductive region C of the back electrode 22 is composited with a metal grid 224 embedded in the TCO layer 223 Electrodes, wherein the TCO is ITO, the thickness of the ITO layer 223 is 300nm, the width of the grid line in the metal grid 224 is 1 μm, the depth is 1 μm, the pattern is a regular hexagon, the side length of the pattern is 85 μm, and the prepared 30cm 2 The photoelectric conversion efficiency of the large-area device cell is more than 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com