Paper diaper capable of effectively resisting bacteria and deodorizing

A technology of diapers and toilet paper, applied in the field of diapers, can solve the problems of easy breeding of bacteria, affecting antibacterial effect, and poor combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

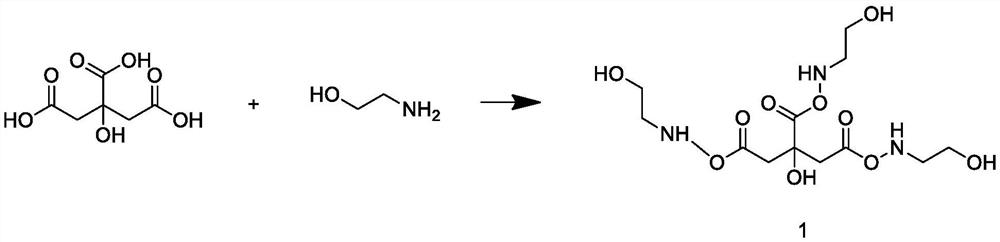

[0032] Prepare antibacterial debonding agent, the preparation steps of this antibacterial debonding agent are as follows:

[0033] Step 1: Add 30mL of chloroform, 15mL of citric acid and 30mL of ethanolamine to the flask under the conditions of heating in a water bath at 45°C and magnetic stirring to generate a pale yellow substance and carry out post-treatment to obtain intermediate product 1; the post-treatment method is to contain The flask with light yellow substance continued to stir and react for 5 minutes, took out the flask heated by the water bath, and cooled to 10°C;

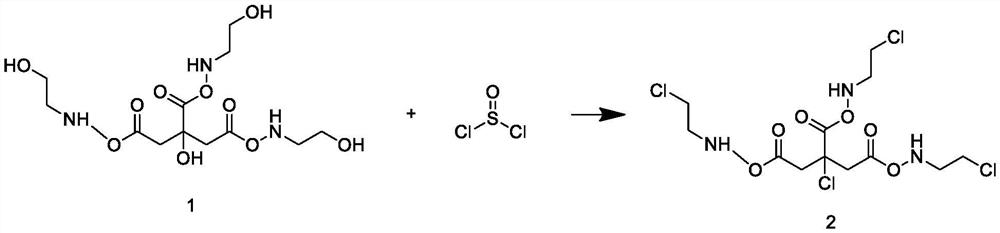

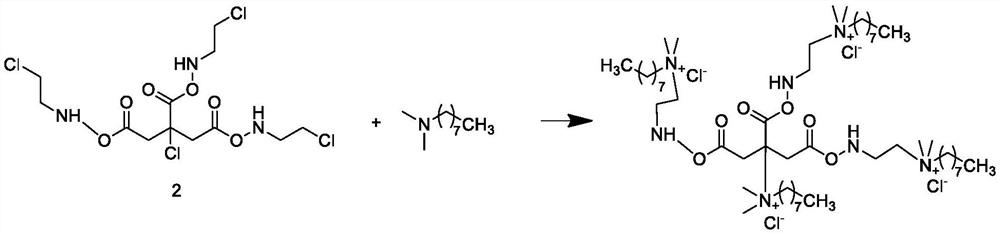

[0034] Step 2: Slowly add the thionyl chloride dropwise into the flask with a dripping bottle, a small amount of gas will be generated during the dropping process, and use the tailpiece to pass into the pre-prepared sodium hydroxide solution, and wait for the thionyl chloride to drip After the addition is completed, carry out post-processing; after the colorless gas is released, take out the flask in t...

Embodiment 2

[0037] Prepare antibacterial debonding agent, the preparation steps of this antibacterial debonding agent are as follows:

[0038] Step 1: Add 30mL of chloroform, 15mL of citric acid and 30mL of ethanolamine to the flask under the conditions of heating in a water bath at 50°C and magnetic stirring, to generate a light yellow substance and carry out post-processing to obtain intermediate product 1; the post-processing method is to contain The flask with light yellow substance continued to stir and react for 5 minutes, took out the flask heated by the water bath, and cooled to 12°C;

[0039] Step 2: Slowly add the thionyl chloride dropwise into the flask with a dripping bottle, a small amount of gas will be generated during the dropping process, and use the tailpiece to pass into the pre-prepared sodium hydroxide solution, and wait for the thionyl chloride to drip After the addition is completed, carry out post-processing; after the colorless gas is released, take out the flask ...

Embodiment 3

[0042] Prepare antibacterial debonding agent, the preparation steps of this antibacterial debonding agent are as follows:

[0043] Step 1: Add 30mL of chloroform, 15mL of citric acid and 30mL of ethanolamine to the flask under the conditions of heating in a water bath at 55°C and magnetic stirring to generate a light yellow substance and carry out post-treatment to obtain intermediate product 1; the post-treatment method is to contain The flask with light yellow substance continued to stir and react for 5 minutes, took out the flask heated by the water bath, and cooled to 15°C;

[0044] Step 2: Slowly add the thionyl chloride dropwise into the flask with a dripping bottle, a small amount of gas will be generated during the dropping process, and use the tailpiece to pass into the pre-prepared sodium hydroxide solution, and wait for the thionyl chloride to drip After the addition is completed, carry out post-processing; after the colorless gas is released, take out the flask in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com