Efficient mirabilite gypsum flotation purification process

A technology of Glauber's salt and gypsum, which is applied in flotation, solid separation, etc., can solve the problems of poor economy, limited industrial application, and high energy consumption, and achieve the effects of improving the whiteness of concentrate, maximizing resource utilization, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

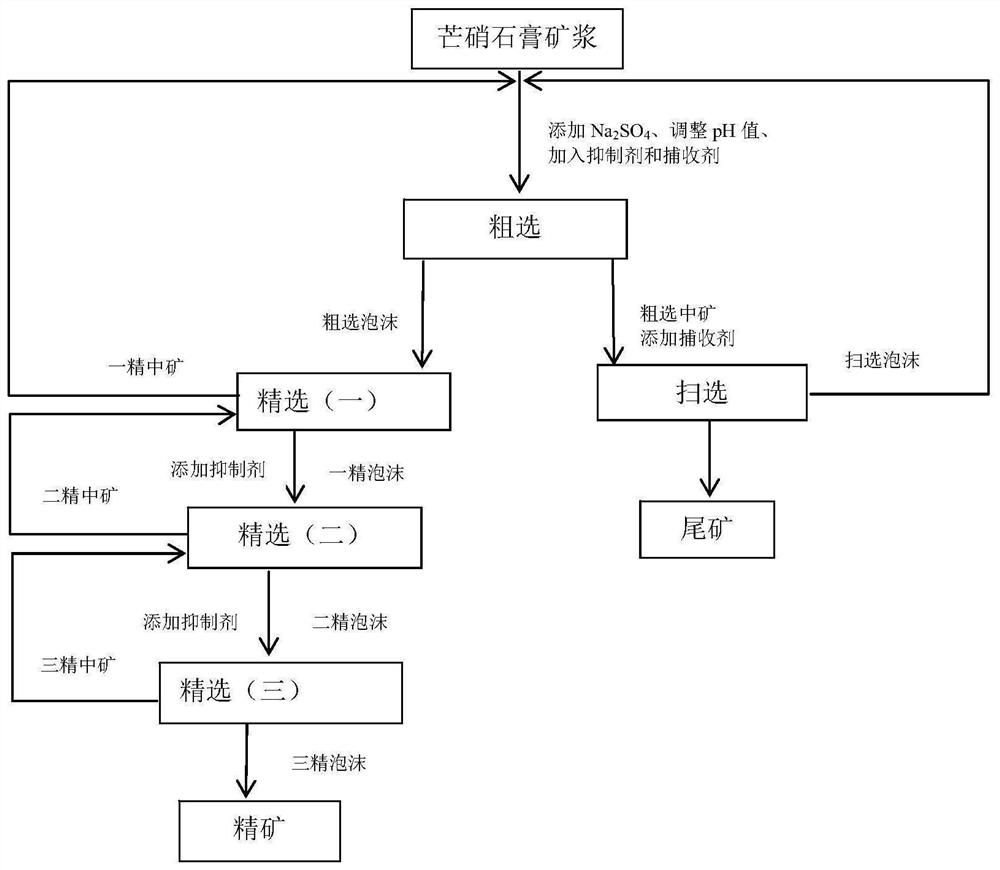

[0039] refer to figure 1 , a high-efficiency Glauber's salt gypsum flotation purification process, specifically comprising the following steps:

[0040] (1) Glauberite ore is prepared into Glauber's salt gypsum slurry; wherein the mass concentration of Glauber's salt gypsum slurry is 16%; wherein the pH value of Glauber's salt gypsum slurry is adjusted to 6;

[0041] (2) Rough separation: Add sodium sulfate, inhibitor and collector to the Glauber's salt gypsum slurry to obtain rough separation foam and rough separation; wherein the temperature of flotation is 25°C, and the scraping time is 5 minutes; the inhibitor It is sodium silicate, and the dosage of sodium silicate is 2000g / t; the collector includes sodium oleate, and the dosage of sodium oleate is 1500g / t; the dosage of sodium sulfate is 1280g / t;

[0042] (3) Sweeping: add collector to the rough selection, obtain the cleaning and tailings, and return the cleaning to the roughing; wherein the collector includes sodium ol...

Embodiment 2

[0047] refer to figure 1 , a high-efficiency Glauber's salt gypsum flotation purification process, specifically comprising the following steps:

[0048] (1) Glauberite ore is prepared into Glauber's salt gypsum slurry; wherein the mass concentration of Glauber's salt gypsum slurry is 30%; wherein the pH value of Glauber's salt gypsum slurry is adjusted to 8;

[0049] (2) Rough separation: Add sodium sulfate, inhibitor and collector to the Glauber's salt gypsum slurry to obtain rough separation foam and rough separation; the temperature of flotation is 35°C, and the scraping time is 6 minutes; the inhibitor It is sodium silicate, and the dosage of sodium silicate is 2600g / t; the collector includes sodium oleate, and the dosage of sodium oleate is 2300g / t; the dosage of sodium sulfate is 2500g / t;

[0050] (3) Sweeping: add collector to the rough selection, obtain the cleaning and tailings, and return the cleaning to the roughing; wherein the collector includes sodium oleate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com