Polyamide resin containing imide structure and preparation method of polyamide resin

A polyamide resin and imide-containing technology, which is applied in the field of polyamide resin containing imide structure and its preparation, can solve the problems of high water absorption of low water-absorbing nylon, barrier properties of polyamide resin, transparency, strength, medium Problems such as electrical degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides the preparation method of the polyamide resin containing imide structure described in above-mentioned technical scheme, comprises the following steps:

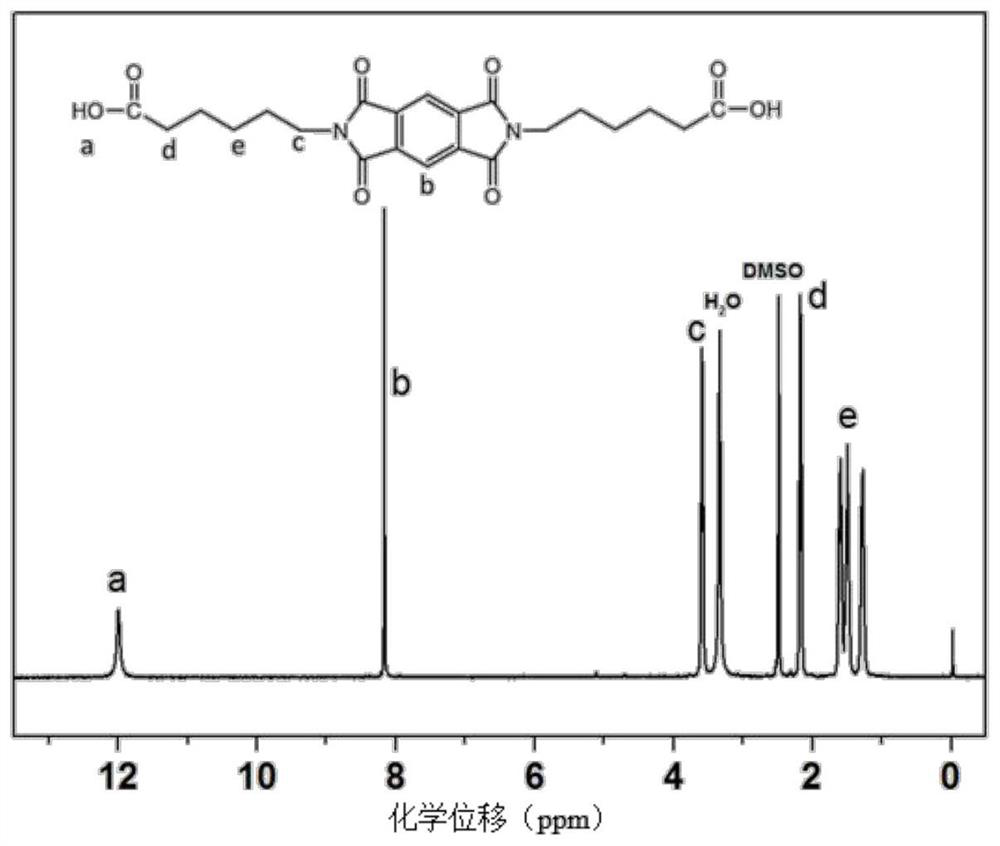

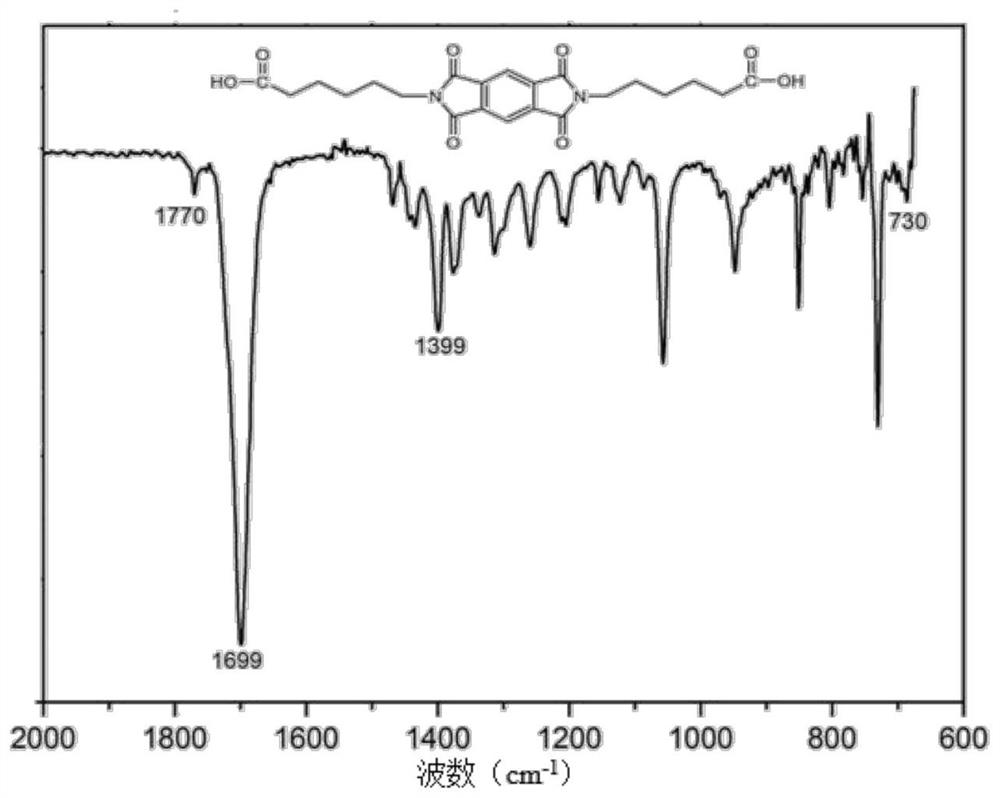

[0057] (1) Mix dianhydride, aminocarboxylic acid, first catalyst, solvent and dehydrating agent, carry out high temperature polycondensation reaction, obtain imide diacid, the chemical structural formula of described imide diacid is as shown in formula (II) ;

[0058]

[0059] In the formula (II), R is a fragment of an aromatic dianhydride and / or an alicyclic dianhydride, and G is a fragment of an aminocarboxylic acid;

[0060] (2) Condensing the imide diacid and the aliphatic diamine obtained in the step (1) in water to obtain a salt of the imide diacid and the aliphatic diamine;

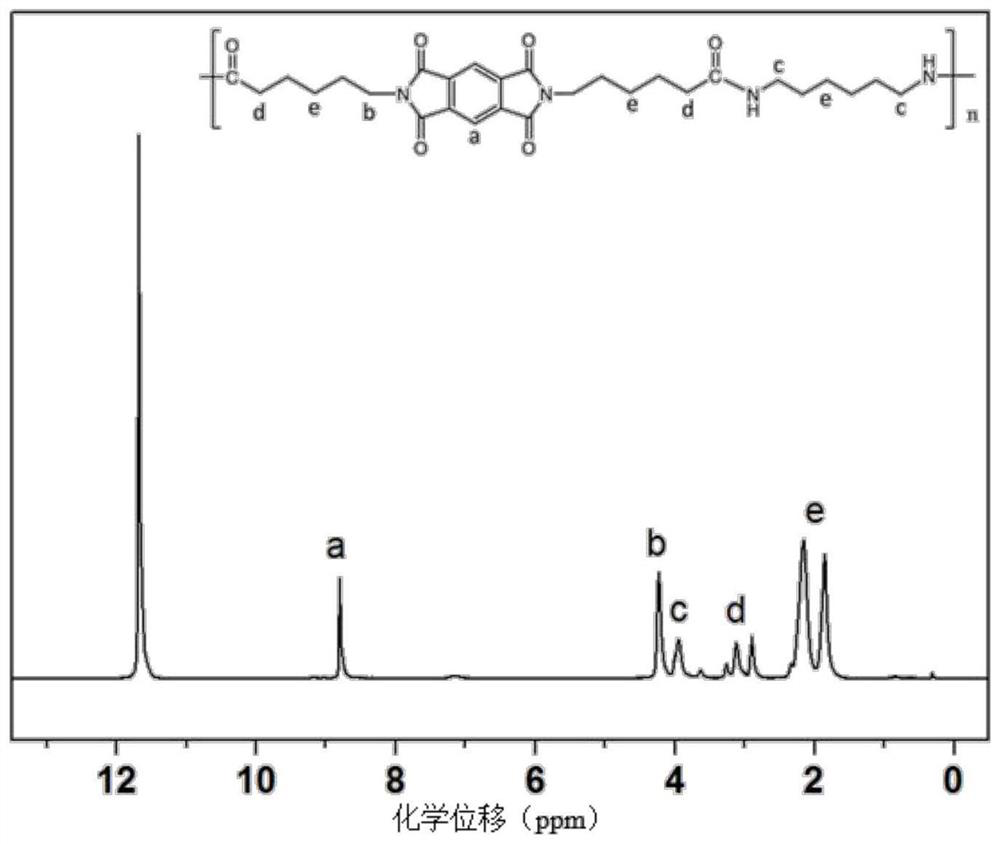

[0061] (3) Mix the imide diacid obtained in the step (2) with the salt of the aliphatic diamine and the second catalyst, and perform a melt polycondensation reaction to obtain a polyamide resin contain...

Embodiment 1

[0101] (1) Feed pyromellitic dianhydride and aminocaproic acid at a material ratio of 1:2.1, stir well in DMF solvent at 80°C, add the first catalyst sodium acetate, dehydrating agent acetic anhydride, 160°C Reflux and keep warm for 6 hours, settle in a large amount of distilled water after the reaction, the product is a white powdery solid, filter with suction, and dry in vacuum to obtain imide diacid with a yield of 90%. Wherein, the mass of the first catalyst is 0.2% of the mass of the dianhydride.

[0102] (2) Add the imide diacid obtained in the step (1) into pure water at 80°C and stir evenly, then dissolve hexamethylenediamine in an appropriate amount of pure water at 80°C, and gradually add it dropwise until complete, at 80°C Stir for 1 hour under heat preservation, the solution is a uniform milky white suspension, and the salt formation is completed; wherein, the ratio of imide diacid to hexamethylenediamine is 1:1 by substance.

[0103] (3) mixing the imide diacid o...

Embodiment 2

[0107] (1) Feed pyromellitic dianhydride and aminotoluic acid at a material ratio of 1:2.1, stir evenly in a mixed solvent of DMAc and acetic acid at 80°C, add the first catalyst sodium acetate, dehydrating agent acetic anhydride , reflux at 160°C for 10 hours, after the reaction was completed, it was settled in a large amount of distilled water, and the product was a white powdery solid, which was filtered by suction and dried in vacuum to obtain imide diacid with a yield of 80%. Wherein, the mass of the first catalyst is 0.2% of the mass of the dianhydride.

[0108] (2) Add the imide diacid obtained in the step (1) into pure water at 80°C and stir evenly, then dissolve decanediamine in an appropriate amount of pure water at 80°C, and gradually add it dropwise until complete, at 95°C Stir for 2 hours under heat preservation, the solution is a uniform light yellow suspension, and the salt formation is completed; wherein, the ratio of imide diacid to decanediamine is 1:1 by sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com