Floating type foam scrubbing rod for gas production of oil and gas field and preparation method of floating type foam scrubbing rod

A foam row and floating technology, which is applied in the field of oil and gas field gas recovery floating foam row and its preparation, can solve the problems of poor adaptability of condensate oil, improve the liquid drainage effect, increase the gas production, and compatibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A floating foam row stick for gas recovery in oil and gas fields, comprising the following components in parts by weight: 15 parts of cocamidopropyl betaine, 15 parts of lauryl amidopropyl hydroxysultaine, and 22 parts of fatty alcohol polyoxyethylene ether 8 parts of xanthan gum, 12 parts of polyethylene glycol, 10 parts of sodium hypochlorite, 25 parts of urea, 9 parts of carboxymethyl cellulose, and 10 parts of sodium chloride.

[0022] The preparation method of above-mentioned soaking stick comprises the steps:

[0023] (1) Import cocamidopropyl betaine, lauryl amidopropyl hydroxysultaine, and fatty alcohol polyoxyethylene ether into the container according to the proportion, stir until mixed evenly, and heat to 52°C;

[0024] (2) Add xanthan gum, polyethylene glycol, sodium hypochlorite, urea, carboxymethyl cellulose, and sodium chloride, stir until evenly mixed, and heat up to 70°C until the material is dried;

[0025] (3) After the mixed material is cooled to ro...

Embodiment 2

[0028] A floating foam row rod for gas recovery in oil and gas fields, comprising the following components in parts by weight: 17 parts of lauryl amidopropyl hydroxysultaine, 15 parts of dodecyl dimethyl betaine, fatty amide polyoxyethylene 22 parts of ether, 11 parts of xanthan gum, 14 parts of polyethylene glycol, 13 parts of sodium hypochlorite, 30 parts of urea, 10 parts of carboxymethyl cellulose, and 12 parts of potassium chloride.

[0029] The preparation method of above-mentioned soaking stick comprises the steps:

[0030] (1) Import lauryl amidopropyl hydroxysultaine, lauryl dimethyl betaine, and fatty amide polyoxyethylene ether into the container according to the proportion, stir until uniformly mixed, and heat to 55°C;

[0031] (2) Add xanthan gum, polyethylene glycol, sodium hypochlorite, urea, carboxymethyl cellulose, and potassium chloride, stir until evenly mixed, and heat up to 75°C until the material is dried;

[0032] (3) After the mixed material is cooled ...

Embodiment 3

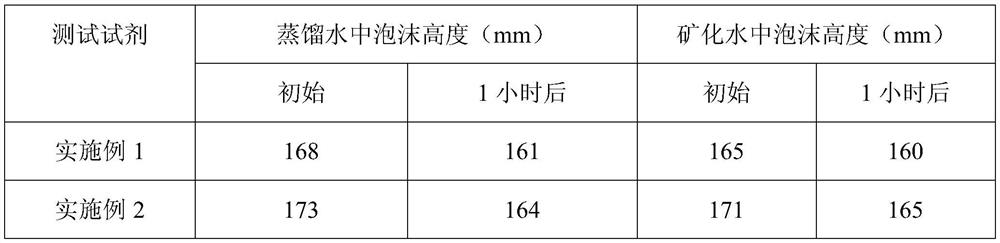

[0035] The bubble discharge sticks of Example 1 and Example 2 were placed in the 70g / L salinity solution, and condensate oil was added to carry out the anti-condensate oil performance test, wherein the liquid carrying capacity of the bubble discharge stick of Example 1 It has reached more than 120ml, and the liquid carrying capacity of the bubble discharge stick in Example 2 has reached more than 130ml, far higher than the 15ml required by the industry standard, showing good anti-condensation oil performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com