Laser fiber power supply working method based on power adaptive feedback

A technology of optical fiber power supply and working method, which is applied in photovoltaic power generation, current collectors, electric vehicles, etc., can solve the problems of poor long-term reliability of laser optical fiber power supply systems, and achieve the effect of improving long-term reliability and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

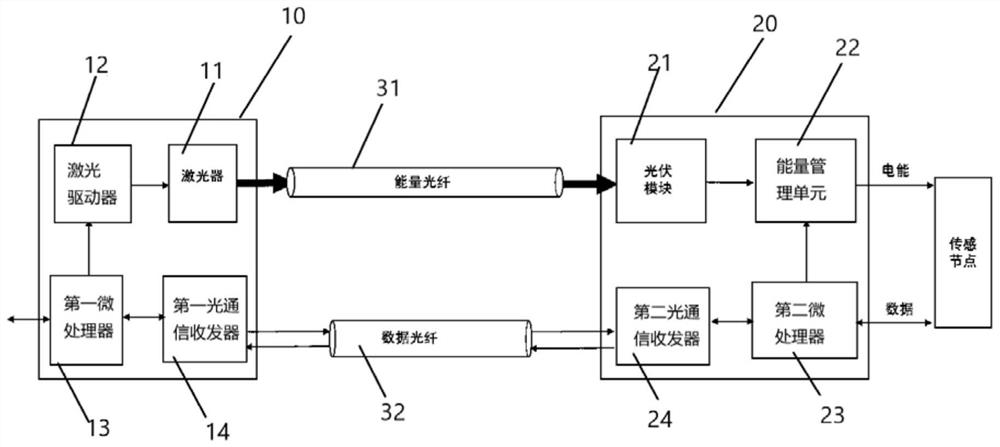

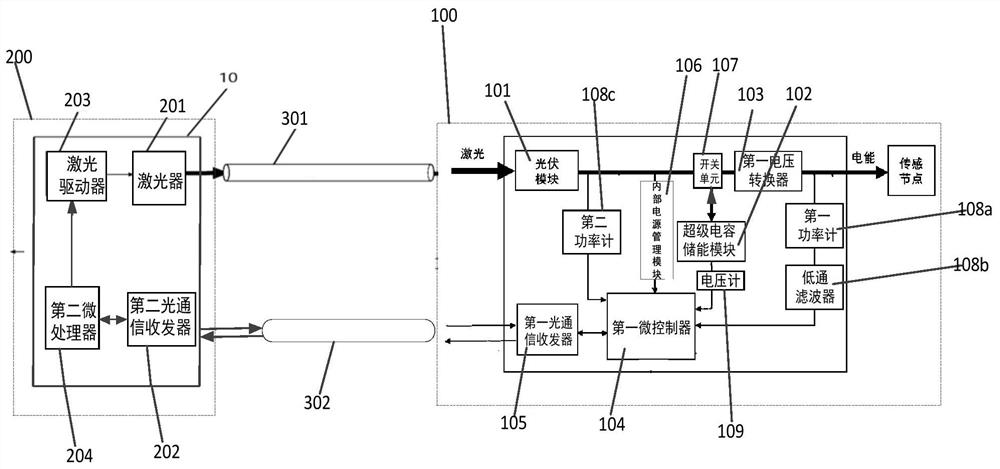

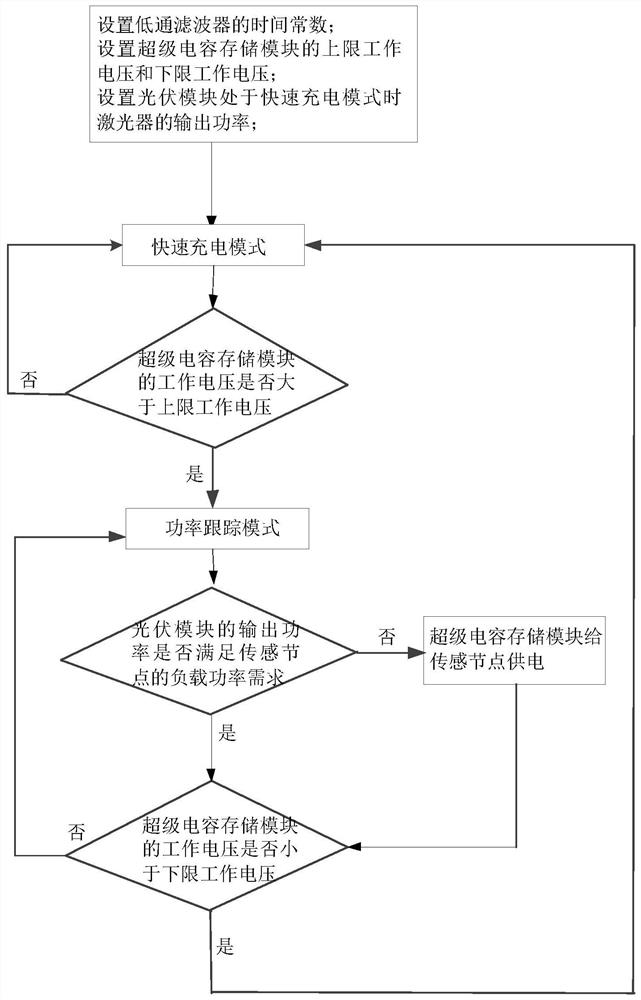

[0034] A laser fiber power supply system, refer to figure 1 , including: a laser power supply base station 10, an optical fiber and a laser power supply receiving end device 20. The laser power supply base station 10 includes: a laser 11 , a laser driver 12 , a first microcontroller 13 and a first optical communication transceiver 14 . The optical fibers include power optical fibers 31 and data optical fibers 32 . The laser power receiving end device 20 includes a photovoltaic module 21 , an energy management unit 22 , a second microcontroller 23 and a second optical communication transceiver 24 .

[0035] The laser 11 is a high-power laser diode. The laser 11 converts electrical energy into light energy, and then transmits it to the laser power receiving end device 20 through an energy fiber. The output power of the laser 11 is regulated via the current of the laser driver 12 . The laser power supply receiving end device 20 receives the laser energy output from the laser p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com