Anticoagulant dense net stent and preparation method thereof

An anti-coagulation and dense mesh technology, applied in the field of anti-coagulation dense mesh stent and its preparation, can solve the problems of thrombus restenosis, vascular intima damage, occlusion, etc., and achieve easy control, inhibition of adhesion and activation , good anticoagulant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

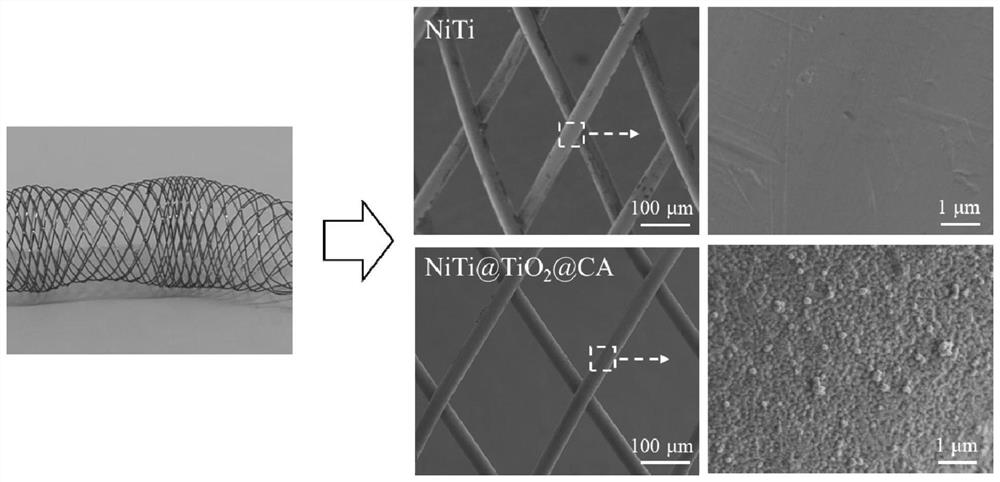

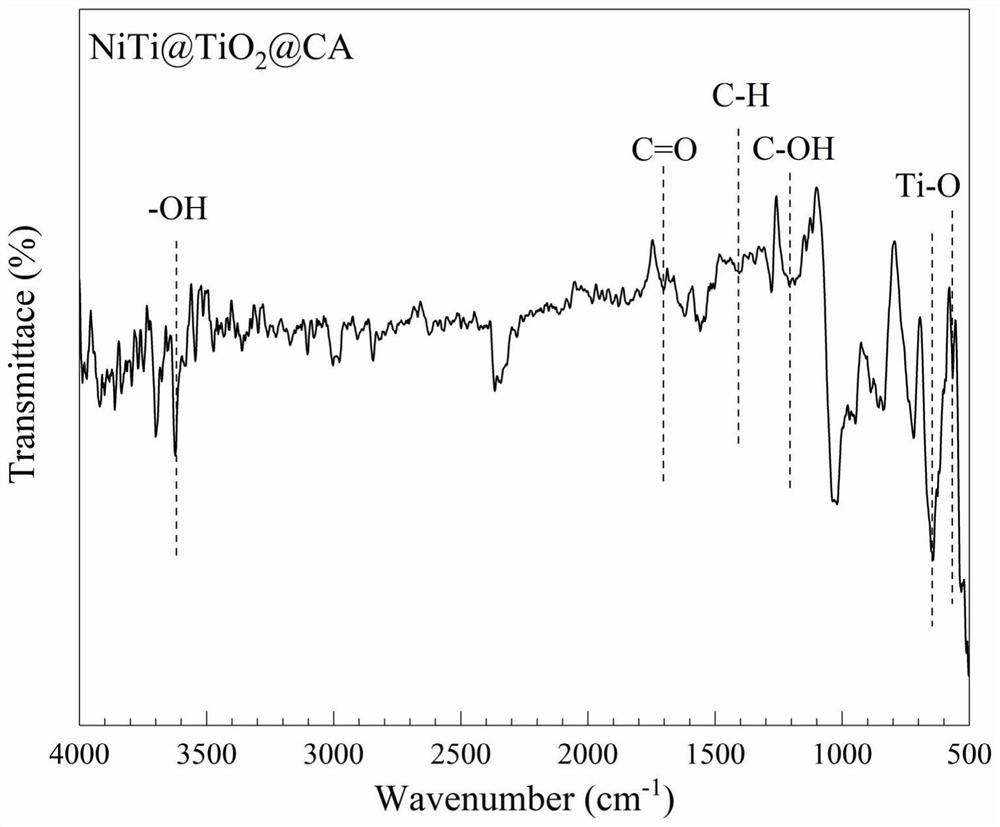

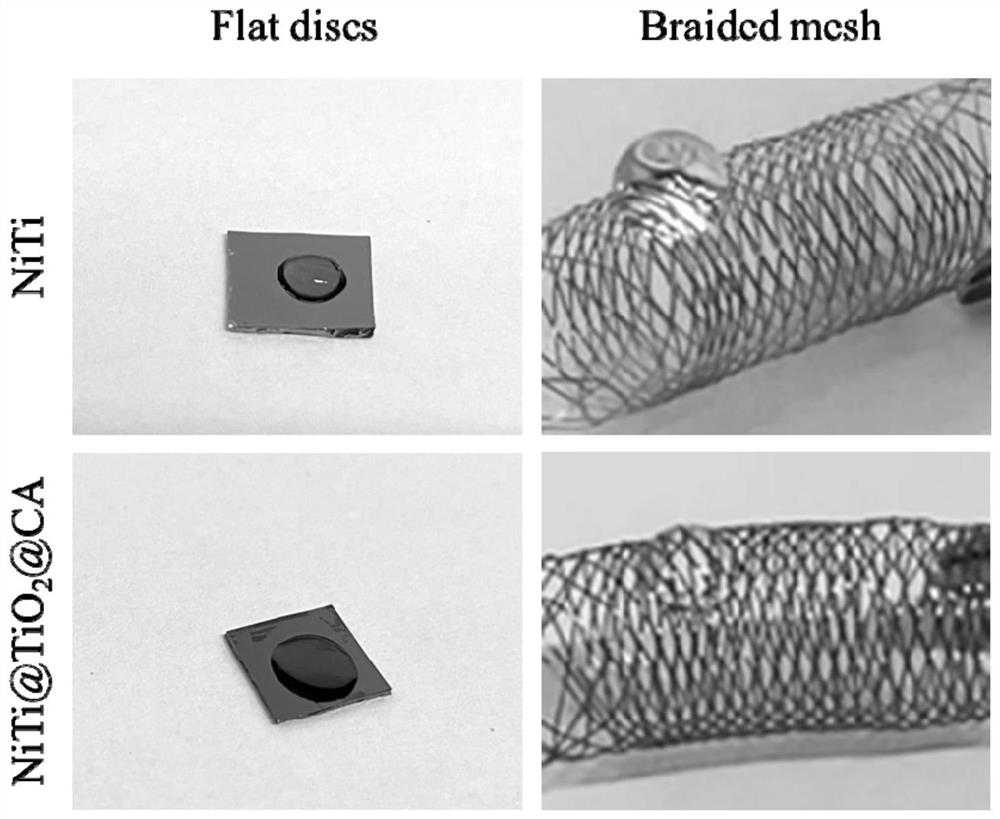

[0033] An anticoagulant dense-mesh stent comprises a nickel-titanium alloy dense-mesh stent base and a citric acid coating bonded to the surface of the nickel-titanium alloy dense-mesh stent base, and the thickness of the citric acid coating is about 300nm.

[0034] The dense-mesh scaffold for promoting endothelialization in this example was prepared through the following steps:

[0035] S1: Place the base of the dense-mesh stent in deionized water, and ultrasonically clean it three times, each time for 5 minutes; then place it in absolute ethanol, and ultrasonically clean it three times, each time for 5 minutes; then place it in acetone, and ultrasonically clean it three times, each time for 5 minutes ; Dry in a vacuum oven at last;

[0036] S2: Submerge the nickel-titanium alloy dense-mesh stent substrate treated by S1 in the treatment solution at a temperature of 50°C, and adjust the pH of the treatment solution to 3.88 with hydrofluoric acid, and take out the dense-mesh st...

Embodiment 2

[0040] An anticoagulant dense-mesh stent comprises a nickel-titanium alloy dense-mesh stent base and an acetylsalicylic acid coating bonded to the surface of the nickel-titanium alloy dense-mesh stent base, and the thickness of the acetylsalicylic acid coating is about 500nm.

[0041] The dense-mesh scaffold for promoting endothelialization in this example was prepared through the following steps:

[0042] S1: Place the base of the dense-mesh stent in deionized water, and ultrasonically clean it three times, each time for 5 minutes; then place it in absolute ethanol, and ultrasonically clean it three times, each time for 5 minutes; then place it in acetone, and ultrasonically clean it three times, each time for 5 minutes ; Dry in a vacuum oven at last;

[0043] S2: Submerge the nickel-titanium alloy dense-mesh stent substrate treated by S1 in the treatment solution at a temperature of 45°C, and adjust the pH of the treatment solution to 3.5 with hydrofluoric acid, and take out...

Embodiment 3

[0047] An anticoagulant dense-mesh support includes a nickel-titanium alloy dense-mesh support base and a tannic acid coating bonded to the surface of the nickel-titanium alloy dense-mesh support base. The thickness of the tannic acid coating is about 100nm.

[0048] The dense-mesh scaffold for promoting endothelialization in this example was prepared through the following steps:

[0049] S1: Place the base of the dense-mesh stent in deionized water, and ultrasonically clean it three times, each time for 5 minutes; then place it in absolute ethanol, and ultrasonically clean it three times, each time for 5 minutes; then place it in acetone, and ultrasonically clean it three times, each time for 5 minutes ; Dry in a vacuum oven at last;

[0050]S2: Immerse the nickel-titanium alloy dense-mesh stent substrate treated by S1 in the treatment solution at a temperature of 55°C, adjust the pH of the treatment solution to 4.0 with hydrofluoric acid, and take out the dense-mesh stent su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com