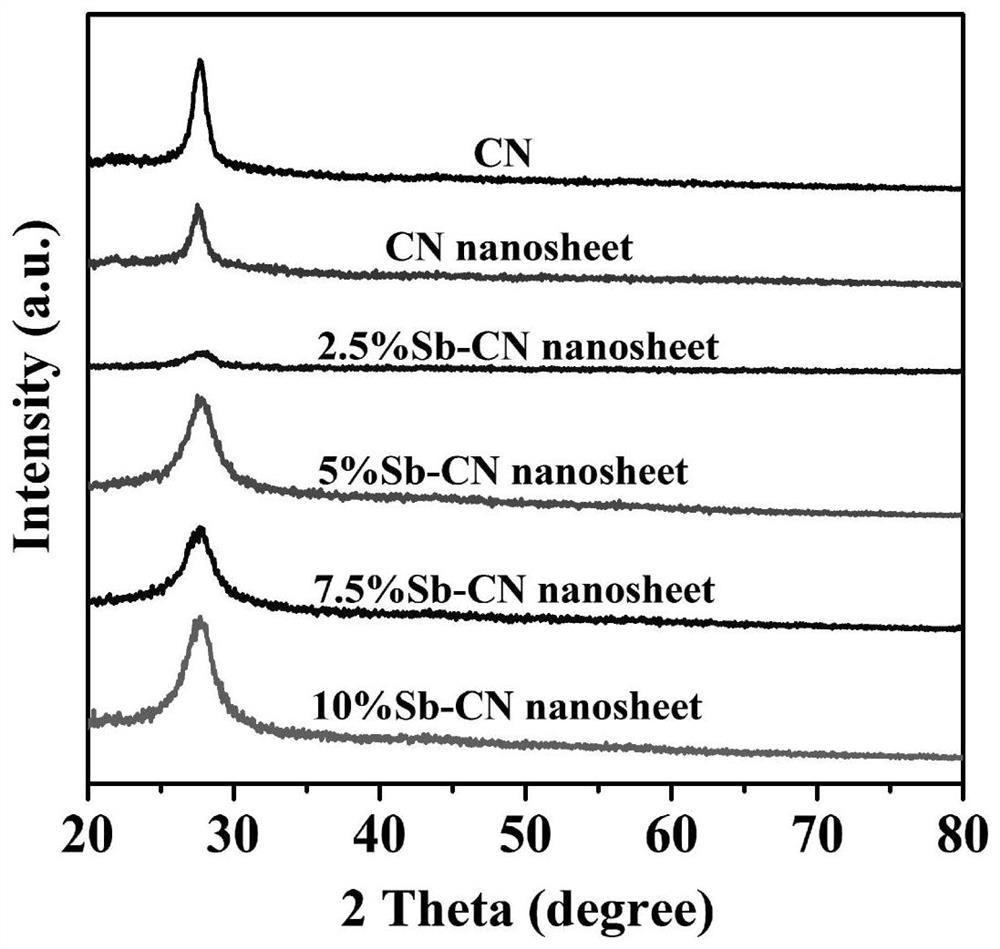

Antimony nanosheet and graphite-like carbon nitride nanosheet composite material and preparation method thereof

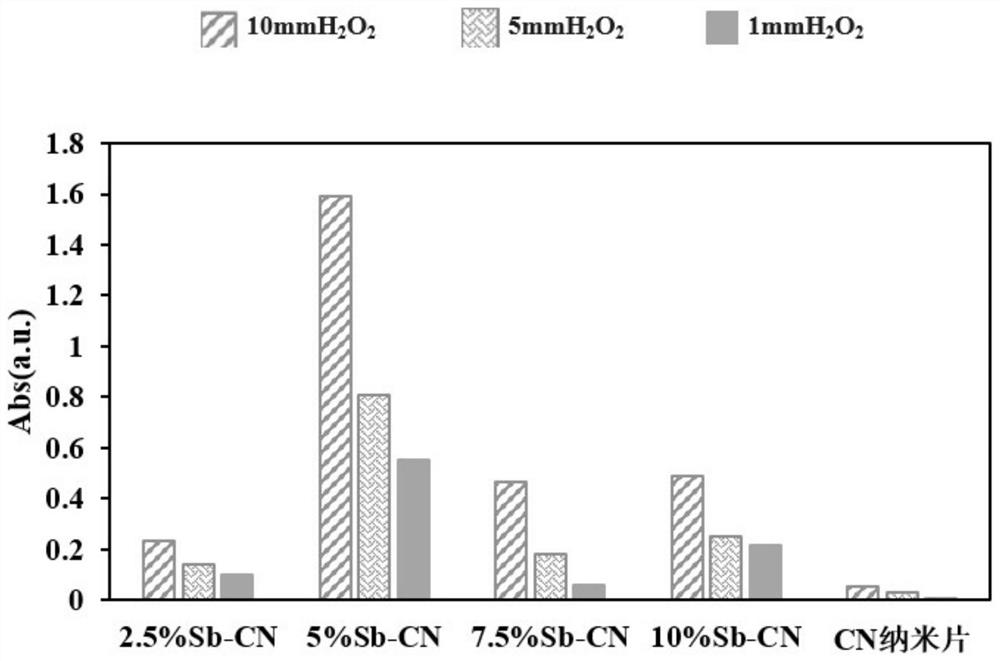

A technology of graphitic carbon nitride and composite materials, which is applied in the field of composite materials and preparation of Sb-CN nanosheets, can solve the problems of high carrier recombination rate, small specific surface area of materials, low catalytic efficiency, etc., and achieves the preparation process. Simple, enhanced electron transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

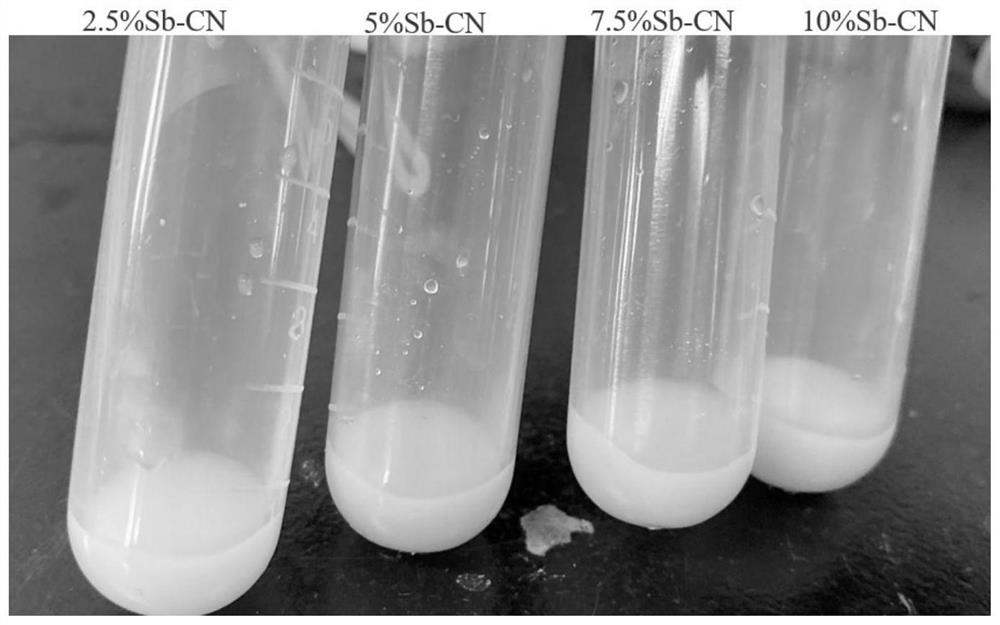

[0029] Embodiment 1: Preparation of 2.5% Sb-CN nanosheet composite material

[0030] (1) Disperse 0.2g of antimony and 0.2g of graphitic carbon nitride with 20mL of concentrated sulfuric acid respectively, stir at 25°C for 4 hours, then stand still for 30min;

[0031] (2) Take 0.5ml of the concentrated sulfuric acid solution of antimony in (1) and add dropwise to 20mL of the concentrated sulfuric acid solution of graphite phase carbon nitride prepared in (1), and continue to stir for 2h;

[0032] (3) At 25 degrees Celsius, add 500ml of ultrapure water with argon gas to the mixed solution obtained in (2) dropwise, finally wash to neutral, and dry in vacuum to obtain a composite material of 2.5% Sb-CN nano piece.

Embodiment 2

[0033] Embodiment 2: Preparation of 5% Sb-CN nanosheet composite material

[0034] (1) Disperse 0.2g of antimony and 0.2g of graphitic carbon nitride with 20mL of concentrated sulfuric acid respectively, stir at 25°C for 4 hours, then stand still for 30min;

[0035] (2) Take 1ml of the concentrated sulfuric acid solution of antimony in (1) and add it dropwise to 20mL of the concentrated sulfuric acid solution of graphite phase carbon nitride prepared in (1), and continue to stir for 2h;

[0036] (3) At 25 degrees Celsius, add 500ml of ultrapure water with argon to the mixed solution obtained in (2) dropwise, finally wash to neutral, and dry in vacuum to finally obtain the composite material 5 %Sb-CN nano piece.

Embodiment 3

[0037] Embodiment 3: Preparation of 7.5% Sb-CN nanosheet composite material

[0038] (1) Disperse 0.2g of antimony and 0.2g of graphitic carbon nitride with 20mL of concentrated sulfuric acid respectively, stir at 25°C for 4 hours, then stand still for 30min;

[0039] (2) Take 1.5ml of concentrated sulfuric acid solution of antimony in (1) and add dropwise to 20mL of concentrated sulfuric acid solution of graphite phase carbon nitride prepared in (1), and continue to stir for 2h;

[0040] (3) At 25 degrees Celsius, add 500ml of ultrapure water with argon to the mixed solution obtained in (2) dropwise, finally wash to neutral, and dry in vacuum to obtain a composite material of 7.5% Sb-CN nano piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com