Casting method of 12-cubic-meter slag ladle

A slag bag and casting technology, applied in the casting field of 12 cubic meters of slag bag, can solve the problems of easy falling off of the bag ears, large sand intake in the sand box, hidden safety hazards, etc., to optimize the heat treatment process, achieve significant economic benefits, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand and implement, the following example illustrates a casting method of a 12 cubic meter slag bag, and the specific steps include:

[0029] 1. Design and production:

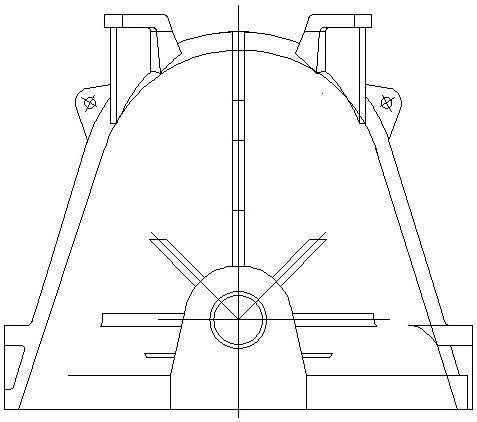

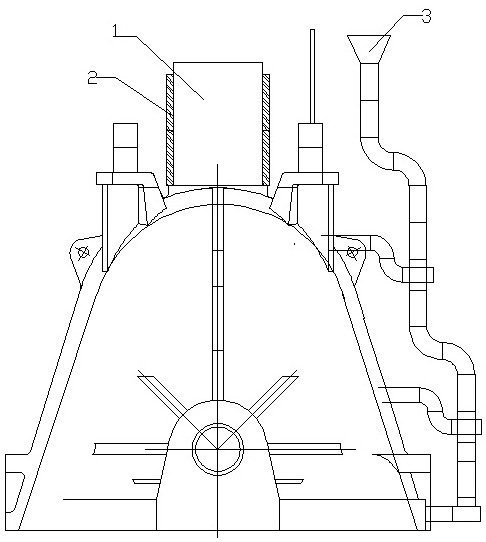

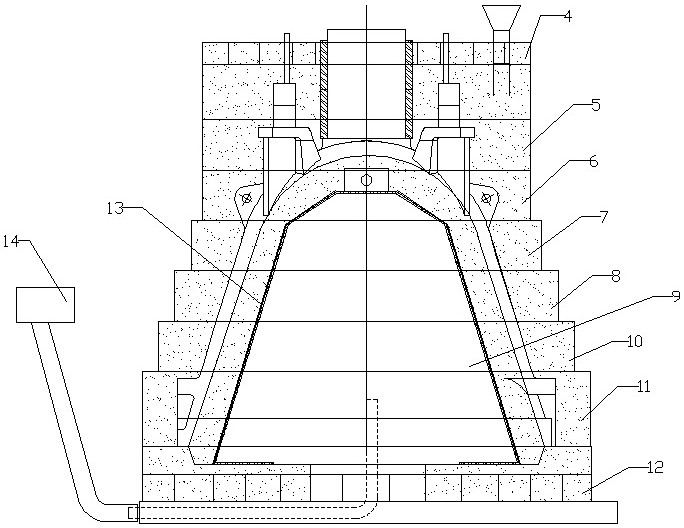

[0030] (1) The casting size is large, Φ3240mm*2910mm (see figure 1 ), the design gating system uses three-layer runners to inject molten steel stably, the vertical main runner is a φ120 ceramic tube, the horizontal runner is a φ100 ceramic tube, and elbows are added to both the straight and runners to ensure smooth flushing of molten steel; The bottom of the slag bag is equipped with a main riser 1 of φ720mm and a height of 1000mm, wrapped with a 60mm thick thermal insulation and heating plate 2 with a height of two floors, and each of the six feet of the slag bag is equipped with 2 φ200mm and a height of 200mm (superimposed) thermal insulation and heating risers, through The magma simulation software conducts repeated analysis, simulation, and correction to finally determine t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com