Environment-friendly low-phosphorus composite scale inhibitor suitable for coexistence working condition of calcium carbonate, calcium sulfate and barium sulfate as well as preparation method and application of environment-friendly low-phosphorus composite scale inhibitor

A composite antiscalant and calcium sulfate technology, which is applied in chemical instruments and methods, descaling and water softening, and special treatment targets, etc., can solve the problem of poor mixed treatment effect of various antiscalants, which affects the normal production of oilfields, Well pipe and sucker rod blockage and other problems, to achieve significant scale inhibition effect, low cost, and reduce the effect of high phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

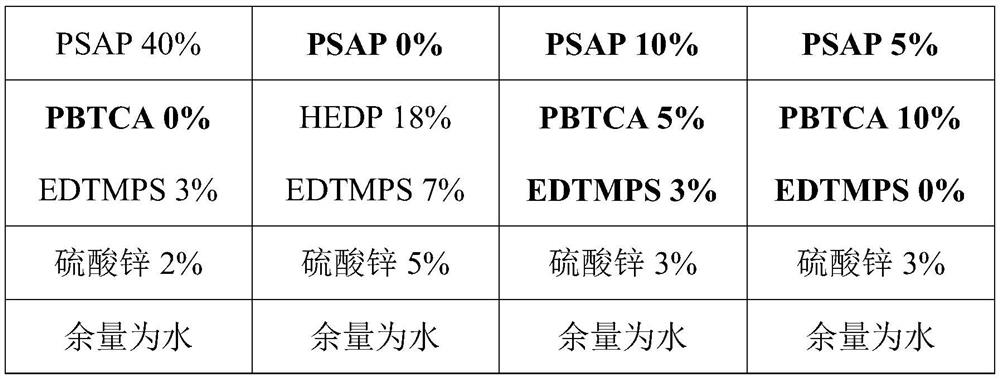

Examples

Embodiment 1

[0039] An environmentally friendly low-phosphorus composite scale inhibitor suitable for the coexistence of calcium carbonate, calcium sulfate and barium sulfate in this embodiment is made of the following raw material components in proportions by mass: sodium polyaspartate ( PASP) 40 parts, 1,2,4-tricarboxylic acid-2-phosphobutane (PBTCA) 10 parts, ethylenediamine tetramethylene phosphonate sodium (EDTMPS) 3 parts, zinc sulfate 2 parts, the balance for water.

[0040]The preparation method of an environment-friendly low-phosphorus composite scale inhibitor suitable for the coexistence condition of calcium carbonate, calcium sulfate and barium sulfate of the present invention is realized through the following steps:

[0041] Step 1. Add 2 parts of zinc sulfate to 45 parts of water, and start heating to raise the temperature. When the temperature rises to 50°C, start stirring until the zinc sulfate is completely dissolved in water;

[0042] Step 2. After mixing 10 parts of 1,2...

Embodiment 2

[0046] An environmentally friendly low-phosphorus composite scale inhibitor suitable for the coexistence of calcium carbonate, calcium sulfate and barium sulfate in this embodiment is made of the following raw material components in proportions by mass: sodium polyaspartate ( PASP) 15 parts, amino trimethylene phosphonic acid (ATMP) 18 parts, ethylenediamine tetramethylene phosphonate sodium (EDTMPS) 7 parts, zinc sulfate 5 parts, and the balance is water.

[0047] The preparation method of an environment-friendly low-phosphorus composite scale inhibitor suitable for the coexistence condition of calcium carbonate, calcium sulfate and barium sulfate of the present invention is realized through the following steps:

[0048] Step 1. Add 5 parts of zinc sulfate to 55 parts of water, and start heating to raise the temperature. When the temperature rises to 50°C, start stirring until the zinc sulfate is completely dissolved in water;

[0049] Step 2. After mixing 18 parts of aminotr...

Embodiment 3

[0053] An environmentally friendly low-phosphorus composite scale inhibitor suitable for the coexistence of calcium carbonate, calcium sulfate and barium sulfate in this embodiment is made of the following raw material components in proportions by mass: sodium polyaspartate ( PASP) 25 parts, 1,2,4-tricarboxylic acid-2-phosphobutane (PBTCA) 15 parts, ethylenediamine tetramethylene phosphonate sodium (EDTMPS) 6 parts, zinc sulfate 3 parts, the balance for water.

[0054] The preparation method of an environment-friendly low-phosphorus composite scale inhibitor suitable for the coexistence condition of calcium carbonate, calcium sulfate and barium sulfate of the present invention is realized through the following steps:

[0055] Step 1. Add 3 parts of zinc sulfate to 55 parts of water, and start heating to raise the temperature. When the temperature rises to 50°C, start stirring until the zinc sulfate is completely dissolved in water;

[0056] Step 2. After mixing 15 parts of 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com