Two-component water-based hydroxyl acrylic polyurethane finishing coating emulsion and preparation method thereof

A technology of hydroxyacrylic polyurethane and hydroxyacrylate, which is applied in the field of two-component waterborne hydroxyacrylic polyurethane topcoat emulsion and its preparation, to achieve the effects of improving water resistance, simple preparation process and long potency period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

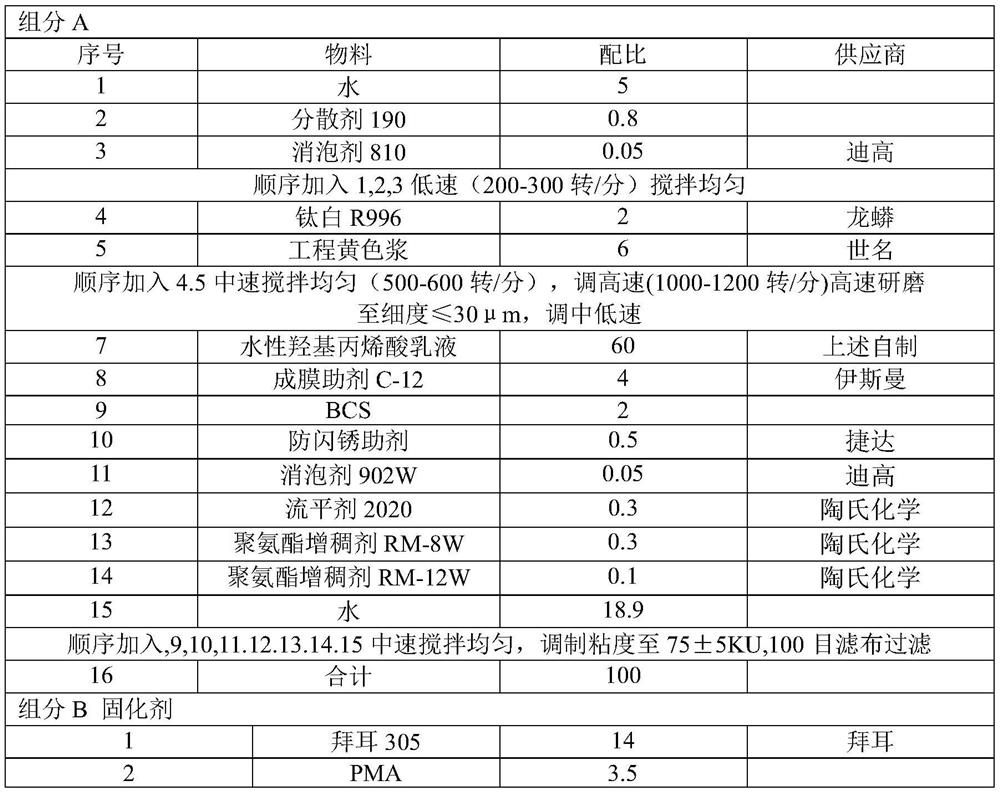

Image

Examples

Embodiment 1

[0031] This embodiment provides a technical solution: a two-component waterborne hydroxyacrylic polyurethane topcoat emulsion and its preparation method, its formula includes 1-2% emulsifier, 45-50% water, 7-12% hydroxyacrylate mono body, 10-20% styrene, 20-28% acrylate monomer, 0.3-1.5% vinyl siloxane, 0.1-1% chain transfer agent and 0.1-1% initiator; the emulsifier includes anionic Emulsifier and nonionic emulsifier, the chain transfer agent includes one or more of mercaptoethanol, mercaptopropanol, and 2-hydroxyethyl mercaptopropionate.

[0032] The hydroxyacrylic acid monomer and the vinyl siloxane are used as functional monomers to improve the water resistance and hardness of the emulsion finished product. During the reaction process, the hydroxyl groups in the hydroxyacrylic acid monomers tend to accumulate or aggregate, resulting in uneven distribution of the hydroxyl groups in the finished emulsion, resulting in a decrease in the hardness of the finished emulsion; ther...

Embodiment 2

[0041] The present embodiment provides a kind of production technology of a kind of two-component waterborne hydroxyacrylic polyurethane topcoat emulsion described in the preparation embodiment 1, and the steps are as follows:

[0042] S1. To prepare the pre-emulsion, take 20-70% of the total amount of emulsifier and 20-60% of the total amount of water and stir and mix it for 10-20 minutes to completely dissolve it, and then add all the styrene and acrylic esters in sequence body, hydroxy acrylate monomer, vinyl siloxane, chain transfer agent, and emulsified at high speed for 30-40 minutes to prepare a pre-emulsion for later use;

[0043] First, by mixing part of the emulsifier and water, a part of the emulsifier aqueous solution is prepared, and at the same time, all the monomers and chain transfer agents are added to the part of the emulsifier aqueous solution for agitation reaction, so that the emulsification reaction is initially started, using part of the emulsifier and wa...

Embodiment 3

[0054] This embodiment provides a technical solution:

[0055] a) To prepare the pre-emulsion, weigh 310g of deionized water, 12g of anionic reactive emulsifier SR10 (Japan Adidas), 10g of isomeric tridecyl alcohol polyoxyethylene ether nonionic emulsifier NOVELUTION 390 (Sasol Functional Chemicals ) stirred rapidly for 15 minutes to dissolve completely, added 120g styrene, 150g methyl methacrylate, 50g butyl methacrylate, 148g ethyl acrylate, 114g butyl acrylate, 93 isooctyl acrylate, 180g hydroxymethacrylate Ethyl ester, 15g of acrylic acid, 10g of mercaptoethanol, and 10g of vinyltrimethoxysilane were stirred at high speed for 30 minutes to obtain a pre-emulsion.

[0056] b) Prepare the bottom material of the kettle, weigh 360g deionized water, 6g reactive emulsifier SR10 (Japan Aidike), 10g NOVELUTION 390 (Sasol functional chemicals), 20.95g sodium bicarbonate aqueous solution (dissolve 0.95g in 20g water sodium bicarbonate solid) was stirred for 15 minutes. heat up.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com