Lightweight high-strength hard alloy material and preparation method thereof

A hard alloy, high-strength technology, applied in the direction of carbide, titanium carbide, etc., can solve the problems of TiC-based cemented carbide tool wear resistance and service life are not ideal, can not meet market demand, tool service life is equivalent, etc., Achieve the effects of less difficulty in production control, low production cost, and improved strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

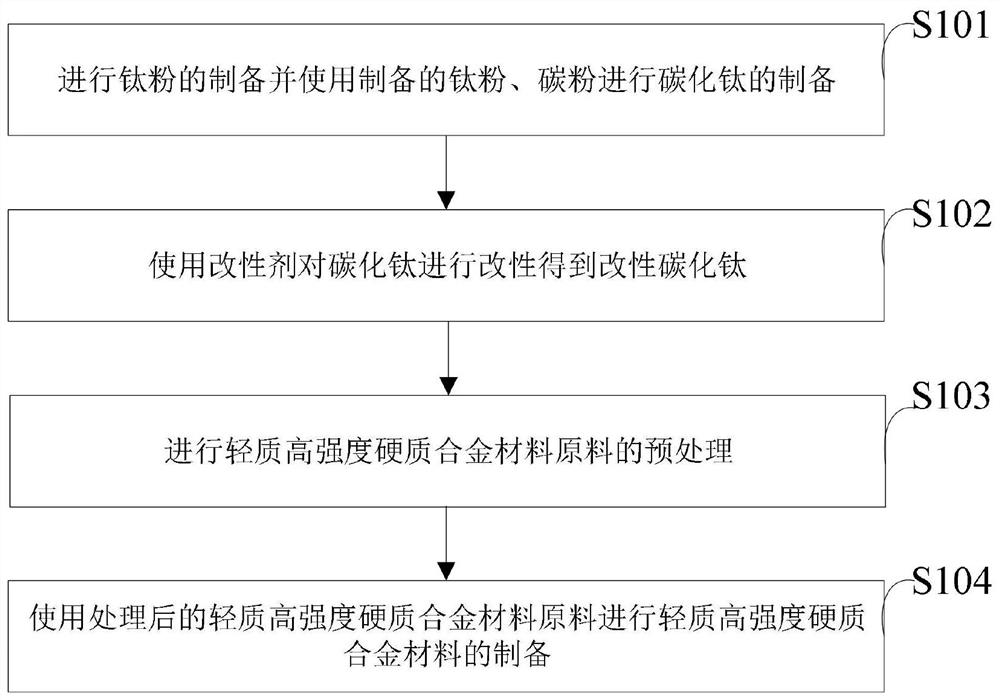

[0033] Such as figure 1 As shown, the preparation method of the lightweight high-strength cemented carbide material provided by the embodiment of the present invention comprises the following steps:

[0034] S101, preparing titanium powder and using the prepared titanium powder and carbon powder to prepare titanium carbide;

[0035] S102, using a modifier to modify titanium carbide to obtain modified titanium carbide;

[0036] S103, performing pretreatment of light-weight and high-strength cemented carbide raw materials;

[0037] S104, using the processed lightweight high-strength cemented carbide raw material to prepare a lightweight high-strength cemented carbide material.

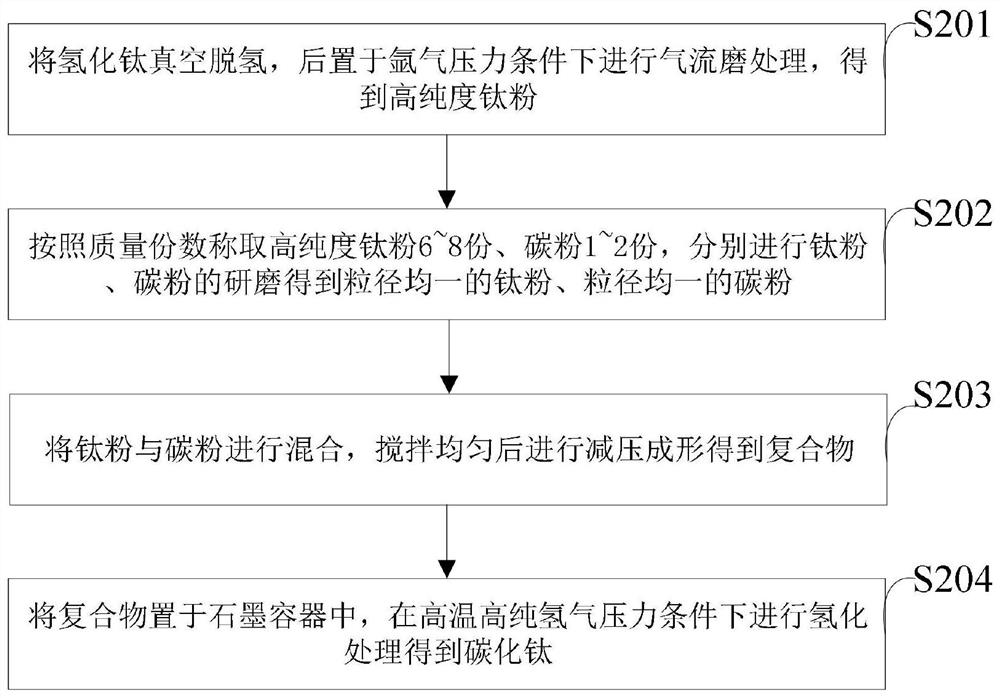

[0038] Such as figure 2 As shown, the preparation of titanium powder provided by the embodiments of the present invention and the preparation of titanium carbide using the prepared titanium powder and carbon powder include:

[0039] S201, dehydrogenating titanium hydride in a vacuum, and then perfor...

Embodiment 1

[0066] A light-weight high-strength hard alloy material, the light-weight high-strength hard alloy material is composed of 6 parts of titanium, 1 part of carbon, 3 parts of zirconium, 2 parts of silicon, 1 part of copper, 2 parts of nickel, Composed of 2 parts of manganese, 1 part of iron, 1 part of niobium and 1 part of chromium.

Embodiment 2

[0068] A light-weight high-strength hard alloy material, the light-weight high-strength hard alloy material consists of 8 parts by mass, 2 parts by carbon, 6 parts by zirconium, 5 parts by silicon, 4 parts by copper, 3 parts by nickel, Composed of 3 parts of manganese, 2 parts of iron, 2 parts of niobium and 3 parts of chromium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com