Method for preparing fermented feed additive through gas explosion

A fermented feed and additive technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, and animal feed molding or processing, can solve the problems of complex operation steps, unfavorable preparation of traditional Chinese medicine, single destruction mode, etc., and achieve relief Toxic and side effects, enhance immunity, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

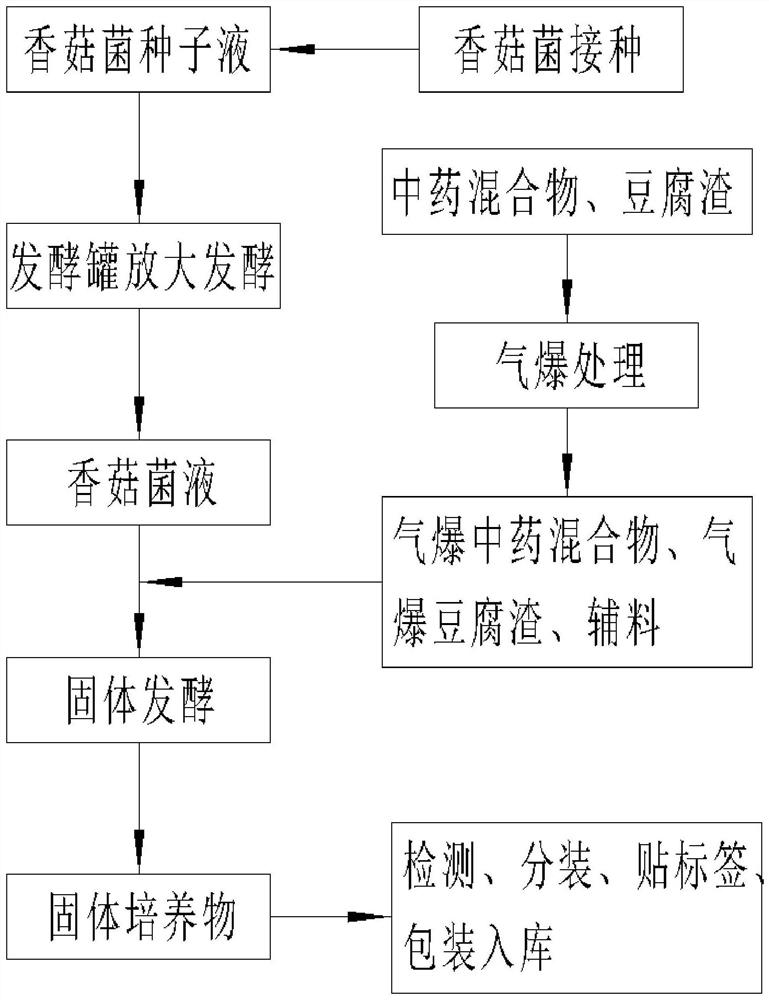

[0030] like figure 1 Shown, a kind of method using gas explosion to prepare fermented feed additive comprises the following steps,

[0031] S1 gas explosion treatment, put the Chinese medicine compound, bean curd residue, and auxiliary materials into the air explosion tank respectively for gas explosion treatment, and obtain the air-exploded Chinese medicine compound, air-exploded bean curd residue, and air-explosion auxiliary materials; the Chinese medicine compound includes the following weight Percentage components, astragalus 24%, Codonopsis 22%, yam 22%, licorice 10%, soybean meal 8%, bean dregs 6%, corncob 8%; auxiliary materials are a mixture of talcum powder and stove core soil, talcum powder and stove core The weight ratio of the soil is 1:1; the gas explosion treatment parameters are as follows: the gas explosion pressure is 0.5MPa, the gas explosion treatment time is 4min, and the moisture content after the gas explosion is controlled at 45wt%.

[0032] S2, seed li...

Embodiment 2

[0038] A method for preparing a fermented feed additive using gas explosion, comprising the following steps,

[0039]S1 gas explosion treatment, put the Chinese medicine compound, bean curd residue, and auxiliary materials into the air explosion tank respectively for gas explosion treatment, and obtain the air-exploded Chinese medicine compound, air-exploded bean curd residue, and air-explosion auxiliary materials; the Chinese medicine compound includes the following weight Percentage components, astragalus 24%, Codonopsis 23%, yam 25%, licorice 10%, soybean meal 5%, bean dregs 5%, corn cob 8%; auxiliary materials are a mixture of talcum powder and stove core soil, talcum powder and stove core The weight ratio of the soil is 1:1; the gas explosion treatment parameters are as follows: the gas explosion pressure is 0.3MPa, the gas explosion treatment time is 6min, and the moisture content after the gas explosion is controlled at 50wt%.

[0040] S2, seed liquid preparation, prepa...

Embodiment 3

[0046] A method for preparing a fermented feed additive using gas explosion, comprising the following steps,

[0047] S1 gas explosion treatment, put the Chinese medicine compound, bean curd residue, and auxiliary materials into the air explosion tank respectively for gas explosion treatment, and obtain the air-exploded Chinese medicine compound, air-exploded bean curd residue, and air-explosion auxiliary materials; the Chinese medicine compound includes the following weight Percentage components, astragalus 20%, Codonopsis 22%, yam 24%, licorice 10%, soybean meal 8%, bean dregs 7%, corncob 9%; auxiliary materials are a mixture of talcum powder and stove core soil, talc powder and stove core The weight ratio of the soil is 1:1; the gas explosion treatment parameters are as follows: the gas explosion pressure is 0.7MPa, the gas explosion treatment time is 3min, and the moisture content after the gas explosion is controlled at 30wt%.

[0048] S2, seed solution preparation, prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com