Composite plant anti-allergy agent, composite plant anti-allergy composition, preparation method of composite plant anti-allergy composition and application of composite plant anti-allergy agent

A technology of plant anti-allergic agent and composition, applied in the field of anti-allergy, can solve skin acne and other problems, achieve the effect of improving anti-oxidation, increasing long-term water content, and enhancing anti-inflammatory and anti-allergic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

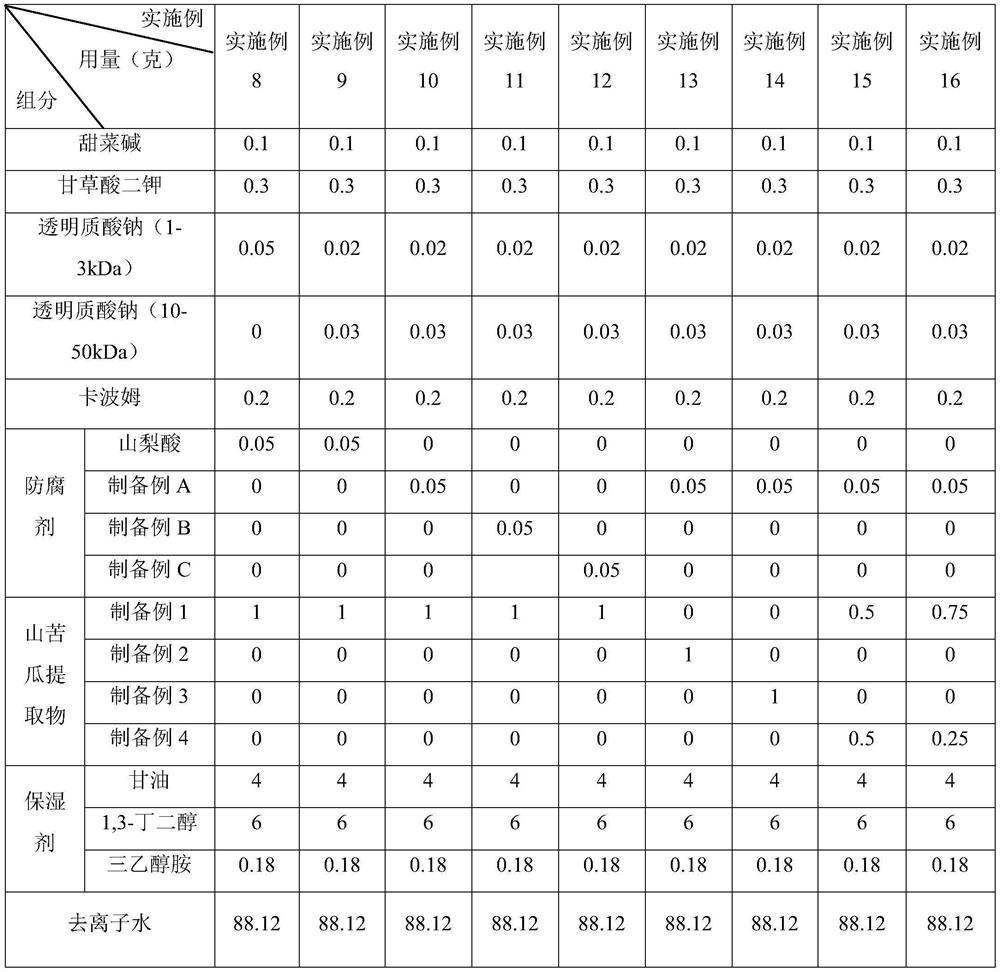

Examples

preparation example 1

[0067] Preparation example 1: a kind of bitter gourd extract, its preparation method is as follows:

[0068] (1) After drying and crushing bitter gourd through a 50-mesh sieve, add ethanol to control the weight ratio of bitter gourd and ethanol, that is, mix bitter gourd: ethanol at a ratio of 1:15 to obtain a mixed solution; Underleaching for 1.5h, then ultrasonic extraction for 2h, and then filtering with a 0.45μm microporous membrane;

[0069] (2) The filtrate obtained after filtering in step (1) is subjected to vacuum rotary evaporation under the condition that the absolute vacuum degree is controlled to be 0.095 MPa to obtain the bitter gourd extract.

preparation example 2

[0070] Preparation example 2: a kind of bitter gourd extract, its preparation method is as follows:

[0071] (1) After drying and crushing bitter gourd through a 40-mesh sieve, add ethanol to control the weight ratio of bitter gourd and ethanol, that is, mix bitter gourd: ethanol at a ratio of 1:10 to obtain a mixed solution; the obtained mixed solution is heated at 20°C Extract for 1 hour, then ultrasonically extract for 0.5 hour, and then filter with a 0.45 μm microporous membrane;

[0072] (2) The filtrate obtained after filtering in step (1) is subjected to vacuum rotary evaporation under the condition that the absolute vacuum degree is controlled to be 0.094 MPa to obtain the bitter gourd extract.

preparation example 3

[0073] Preparation example 3: a kind of bitter gourd extract, its preparation method is as follows:

[0074] (1) After drying and crushing bitter gourd through an 80-mesh sieve, add ethanol to control the weight ratio of bitter gourd and ethanol, that is, mix bitter gourd:ethanol at 1:20 to obtain a mixed solution; the obtained mixed solution is heated at 30°C Extract for 2 hours, then ultrasonically extract for 3 hours, and then filter with a 0.45 μm microporous membrane;

[0075] (2) The filtrate obtained after filtering in step (1) is subjected to vacuum rotary evaporation under the condition that the absolute vacuum degree is controlled to be 0.096 MPa to obtain the bitter gourd extract.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com