Powder aerosol capable of resisting to idiopathic pulmonary fibrosis and preparation method thereof

A technology of pulmonary fibrosis and powder spray, which is applied in the field of anti-idiopathic pulmonary fibrosis powder spray and its preparation, and can solve the problems of poor drug efficacy and poor lung deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Prepare micropowder.

[0048] 1. Put pirfenidone, distearoylphosphatidylcholine and lecithin at room temperature for 20 minutes, weigh pirfenidone, distearoylphosphatidylcholine, lecithin and chloride Calcium, water and ethyl acetate, spare;

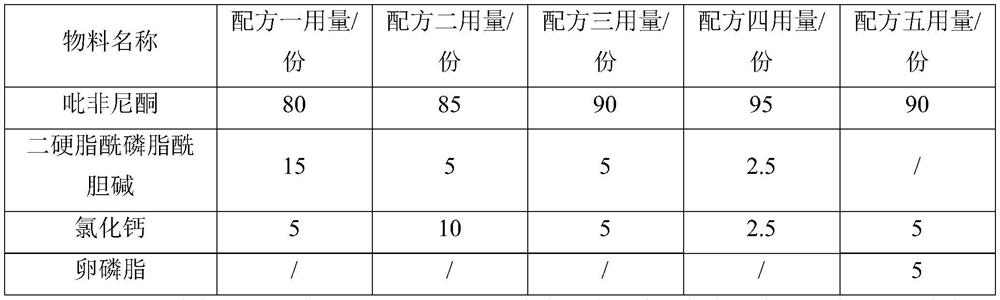

[0049] Table 1 Micropowder formula table

[0050]

[0051] 2. According to the formula in Table 1, put pirfenidone, distearoylphosphatidylcholine, and lecithin into the ethyl acetate solution, stir to dissolve it; dissolve calcium chloride in water, and set aside;

[0052] 3. Pour the ethyl acetate solution obtained in step 2 into a stirring tank with an ultrasonic function, add water dissolved in calcium chloride into it, stir for 30 minutes, and set the ultrasonic oscillation frequency to 20-130KHz. , set the frequency of ultrasonic oscillation to 80KHz, and after 30 minutes of ultrasonication, the drug-containing emulsion is obtained;

[0053] 4. Use a peristaltic pump to pump the drug-containing emulsion obtained in step...

Embodiment 2

[0060] Determination of various data indicators of micropowder.

[0061] The micropowder that obtains in embodiment 1 is carried out each data index measurement, adopts graduated measuring cylinder method to measure bulk density, adopts fillet cone method to measure angle of repose, adopts specific surface and pore size distribution meter to measure, and the results are as follows:

[0062] Table 2 The specific surface area of different proportioning micropowders

[0063] group Bulk density g / ml Angle of repose° Specific surface area m 2 / g

recipe one 0.082 62 12.7028 recipe two 0.087 56 11.6099 Recipe three 0.089 50 13.928 Recipe 3-2 0.12 48 6.2532 Recipe four 0.092 53 12.3025 Recipe five 0.085 58 7.9524

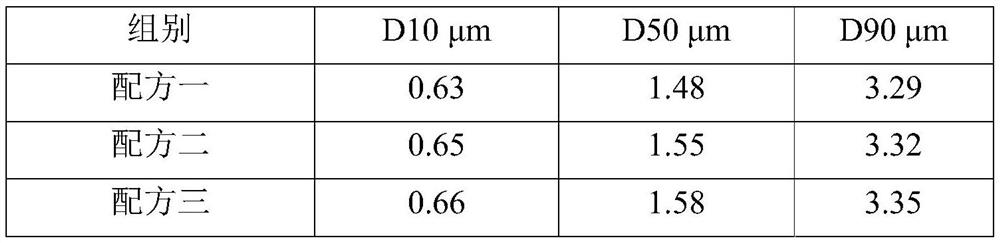

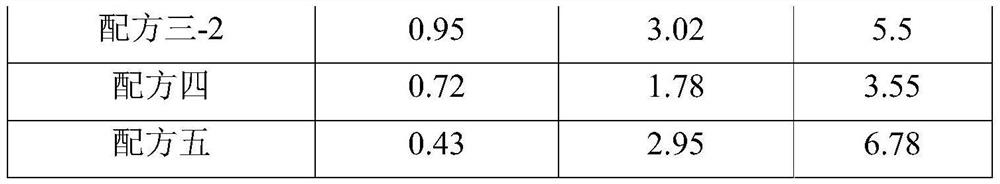

[0064] Table 3 Geometric diameters of micropowders with different ratios Laser particle size analyzer was used to detect the geometric diameters of micropowders, the results are as follows:

[0065] ...

Embodiment 3

[0069] conditioning test.

[0070] The micropowder obtained by spray drying is mainly amorphous, which needs to be transformed into a stable crystalline state under the combination of temperature and relative humidity. The micropowder obtained in step 6 of Example 1 is placed in an environment of 25±5° C. and 65±15% RH, and the stability time is ≥240 minutes.

[0071]In this example, the micropowder was placed in an environment of 25°C and 75% RH, and was stabilized for 360 minutes, and the moisture content and crystal form before and after conditioning were compared. The micropowder obtained in the step is placed simultaneously in an environment of 30°C and 85% RH, and is stable for 360 minutes. This sample is marked as formula 3-3, and the results are compared, as shown in the following table:

[0072] Each formula conditioning result of table 4

[0073] group Moisture content before conditioning% Moisture content after conditioning% pre-conditioning crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com