Flaky CeO2/UIO-66-NH2 composite photocatalytic material and preparation method thereof

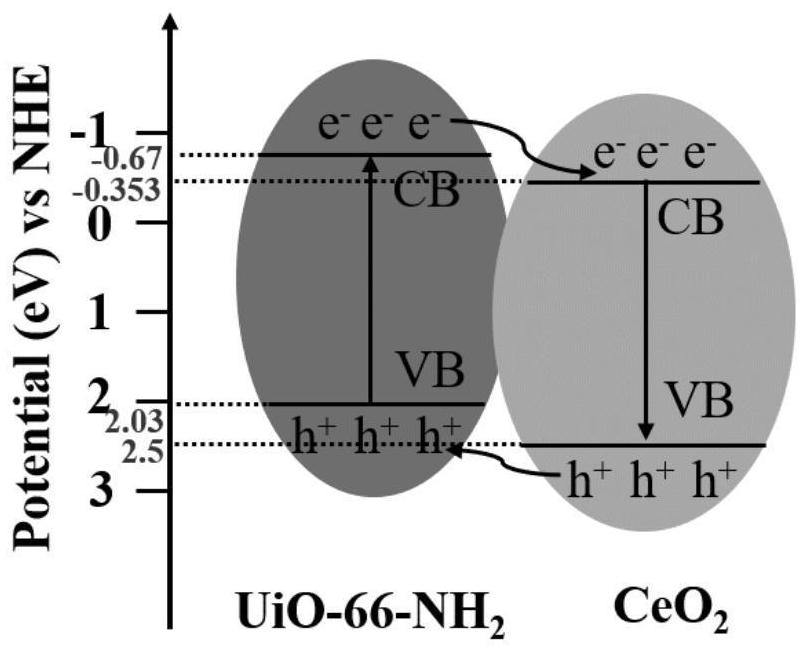

A UIO-66-NH2, composite photocatalysis technology, used in organic compound/hydride/coordination complex catalysts, catalyst activation/preparation, chemical instruments and methods, etc. The problems of poor photocatalytic degradation performance and poor electron transport ability can improve the light absorption efficiency, improve the photocatalytic activity, and reduce the recombination rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In order to solve the technical problem of low removal efficiency of organic pollutants by existing catalysts, the embodiment of the present invention provides a flake CeO 2 / UIO-66-NH 2 The preparation method of composite photocatalytic material comprises the following steps:

[0034] S1. Preparation of CeO by water bath synthesis method 2 nanosheet precursors, followed by calcining the CeO 2 Nanosheet precursors, resulting in CeO 2 Nanosheets;

[0035] S2, ultrasonically dispersing zirconium tetrachloride and 2-amino-1,4 phthalic acid in a solvent, and then the CeO 2 Nano flakes are added to the solvent, mixed evenly, kept at a temperature of 100-180°C for 12-48h, then separated and dried to obtain flake CeO 2 / UIO-66-NH 2 Composite photocatalytic materials.

[0036] A major problem of existing catalysts is the poor photocatalytic performance due to the fast recombination rate of photogenerated carriers, resulting in low removal efficiency for organic pollutant...

Embodiment 1

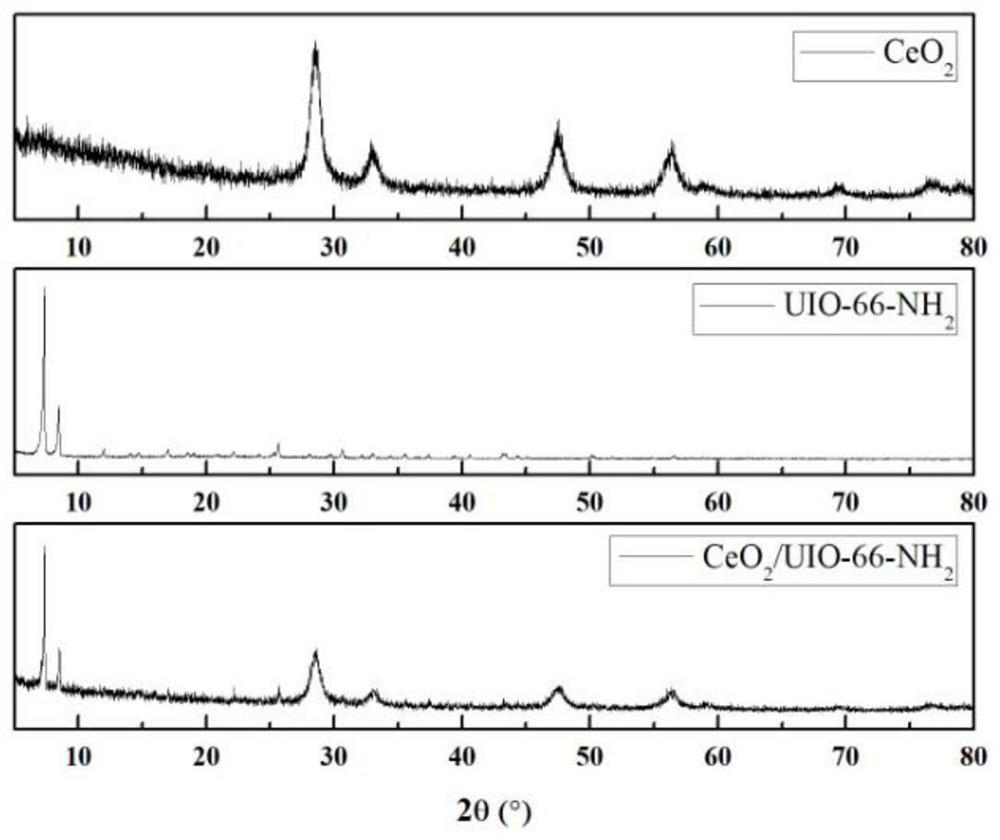

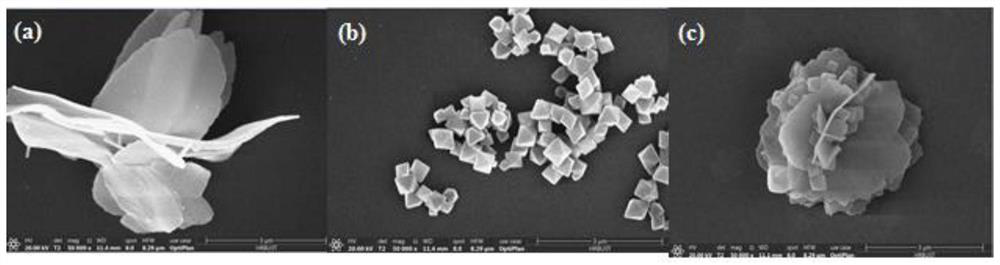

[0052] A flake CeO 2 / UIO-66-NH 2 Composite photocatalytic material, the flake CeO 2 / UIO-66-NH 2 Composite photocatalytic materials including CeO with 3D flower-like morphology 2 nanosheets and dispersion deposited on the CeO 2 UIO-66-NH in the middle of the interlayer of nanosheets 2 nanoparticles.

[0053] The flaky CeO 2 / UIO-66-NH 2 The preparation method of composite photocatalytic material comprises the following steps:

[0054] S1. Dissolve 1.39g of cerium nitrate hexahydrate and 0.75g of ammonium bicarbonate in 200mL of deionized water respectively, stir magnetically until the cerium nitrate hexahydrate and ammonium bicarbonate are completely dissolved and the solution is evenly mixed, then quickly pour the ammonium bicarbonate solution into In the cerium nitrate solution, stir at 0°C for 30 minutes for water bath reaction. After the reaction is completed, filter the reaction solution to collect the precipitate, dissolve the precipitate in deionized water, and...

Embodiment 2

[0061] Embodiment 2 is basically the same as embodiment 1, and its difference is: described flaky CeO 2 / UIO-66-NH 2 CeO in composite photocatalytic materials 2 with UIO-66-NH 2 The mass ratio is 1.5:1.

[0062] Observing the flaky CeO of the present embodiment by a scanning electron microscope (SEM) 2 / UIO-66-NH 2 Microscopic morphology of composite photocatalytic materials, the results are as follows Figure 5 shown. Depend on Figure 5 It can be seen that CeO 2 Nanosheets appear agglomerated and stacked, some UIO-66-NH 2 Nanoparticles suffer from insufficient binding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com