Method for preparing zinc oxide ultrafine powder by using zinc skins of waste zinc-manganese batteries

A zinc-manganese battery, zinc oxide technology, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low added value of recycled products, pollution, resources environmental waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

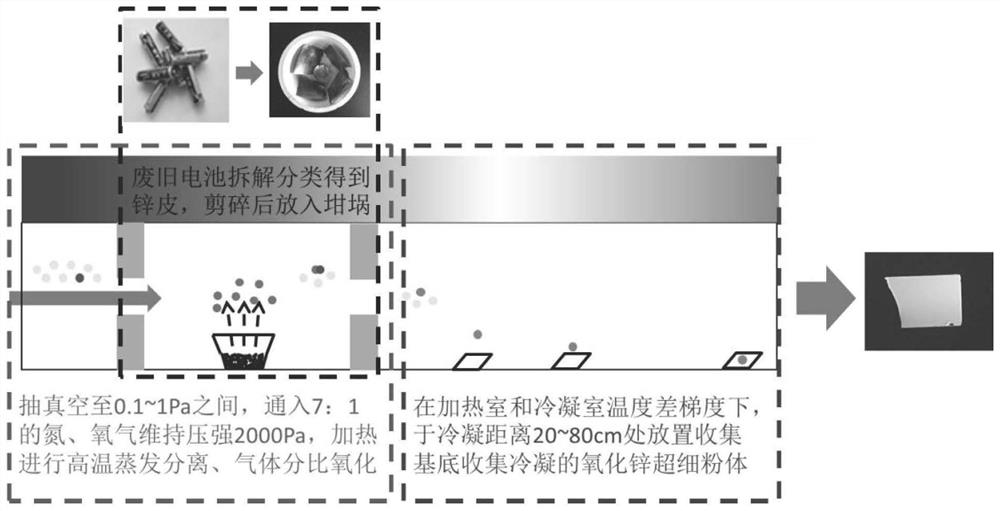

[0044]First, the waste zinc-manganese battery is disassembled and separated, and the obtained zinc skin is cut into pieces and put into the crucible, and then the crucible is put into the heating chamber of the vacuum furnace. Place a glass slide in the cooling chamber as a collection substrate. For details on the location of the crucible and collection base, see figure 1 shown. After the vacuum furnace is sealed, start the vacuum pump group to exhaust the air in the furnace, so that the vacuum degree in the furnace is at 0.1Pa, so as to avoid the metal from being oxidized during the heating process. First turn on the heating switch of the heating chamber (reaction chamber), and heat the reaction chamber to 450°C at a heating rate of 10°C / min. 2000Pa, then continue to heat until the temperature reaches 850°C, and keep it for 30 minutes. Zinc oxide vapor enters the condensation chamber with the air flow, and the condensation temperature is controlled at 50°C. Due to the huge ...

Embodiment 2

[0046] First, the waste zinc-manganese battery is disassembled and separated, and the obtained zinc skin is cut into pieces and put into the crucible, and then the crucible is put into the heating chamber of the vacuum furnace. Place a glass slide in the cooling chamber as a collection substrate. For details on the location of the crucible and collection base, see figure 1 shown. After the vacuum furnace is sealed, start the vacuum pump group to exhaust the air in the furnace, so that the vacuum degree in the furnace is at 1Pa, so as to avoid the metal from being oxidized during the heating process. First turn on the heating switch of the reaction chamber, and heat the reaction chamber to 450°C at a heating rate of 10°C / min (if the temperature is lower than 400°C, zinc will not evaporate to the gas phase, and zinc oxide powder cannot be generated; if the temperature is higher than 500°C, If zinc enters the gas phase too early, it will be directly condensed into zinc powder (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap