System and method for preparing novel biomass carbon source through enhanced anaerobic fermentation of organic garbage

A biomass carbon source, organic waste technology, applied in fermentation, organic fertilizer, fatty material recovery and other directions, can solve the problems of low effective COD equivalent, poor product stability, high production cost, and achieve convenient optimization and product additional High-value, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

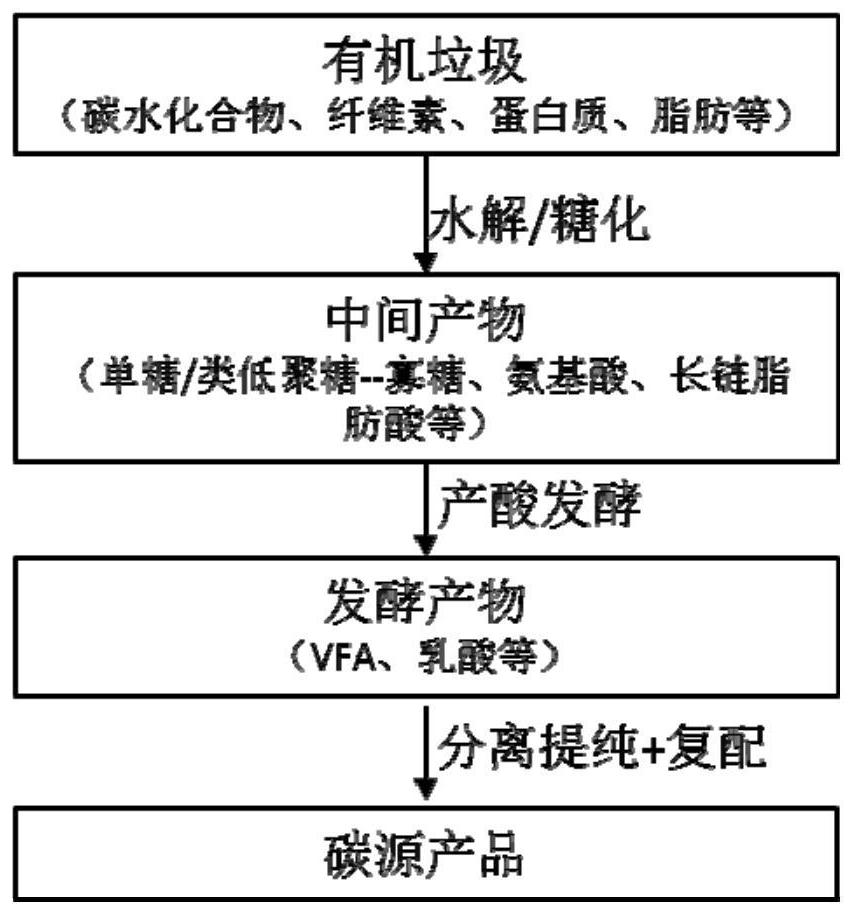

Problems solved by technology

Method used

Image

Examples

Embodiment 1

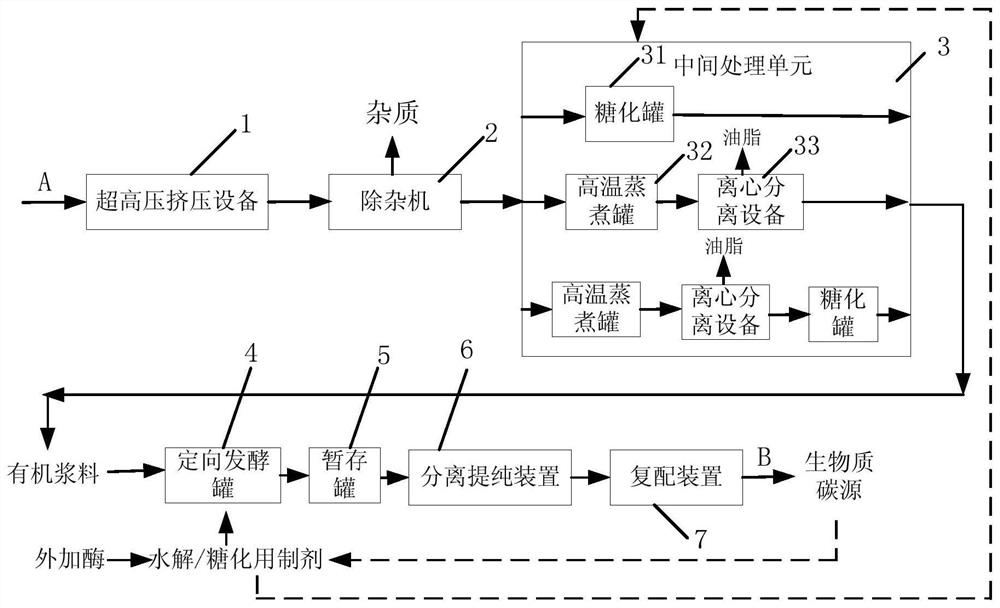

[0068] see image 3 , this embodiment provides a method for preparing a new type of biomass carbon source by enhanced anaerobic fermentation of organic waste, using the system of the present invention, including:

[0069] Food waste (100t / d, solid content 10%~15%) is fed and pretreated by ultra-high pressure extrusion equipment to make pulp, and impurities (20t / d) are removed by the impurity remover, and the slurry is transported Go to the high-temperature cooking tank for cooking. The heating method is heated by a steam (10t / d) injector. The heating temperature reaches about 70-80°C, and it is kept in the high-temperature cooking tank for 2 hours; The separator separates three phases of solid (12t / d), liquid (74t / d) and oil (4t / d), and the separated crude oil is transported to a biodiesel factory as raw material; the obtained 56t liquid phase organic slurry is used for Biogas is produced by anaerobic fermentation, and the steam produced by the gas-fired boiler is used for sy...

Embodiment 2

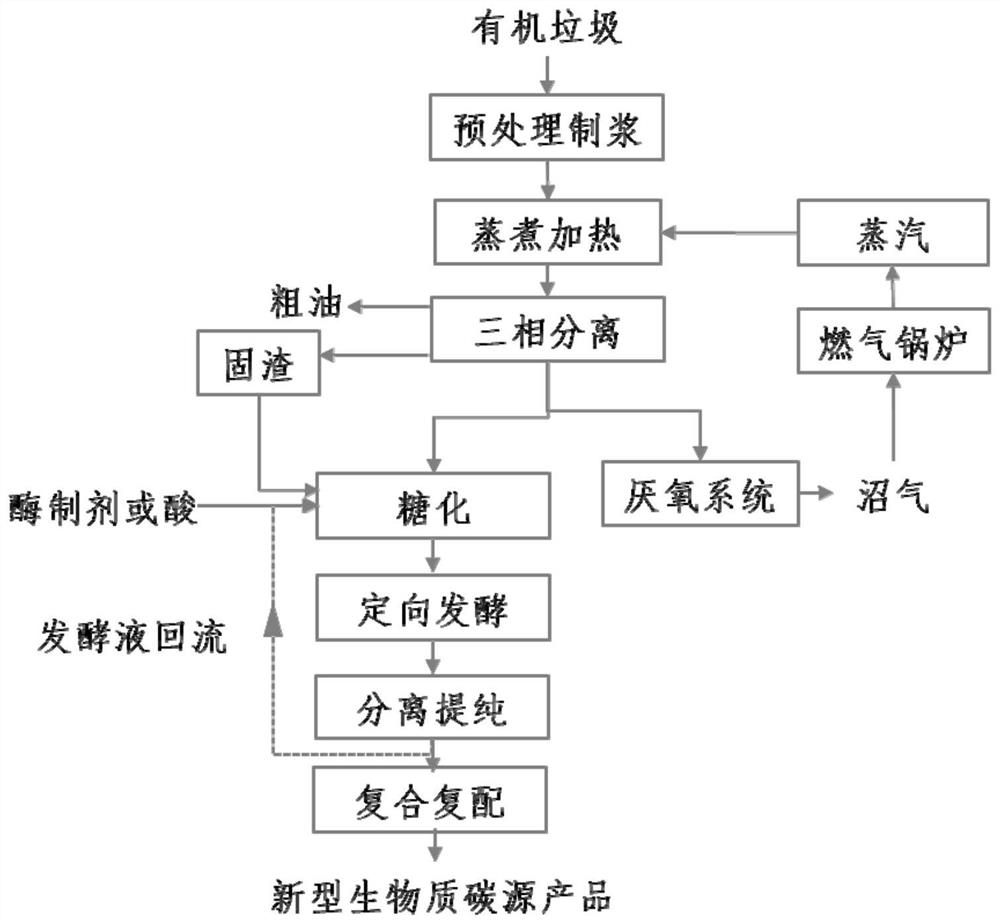

[0071] see Figure 4 , this embodiment provides a method for preparing a new type of biomass carbon source by enhanced anaerobic fermentation of organic waste, using the system of the present invention, including:

[0072] Food waste (100t / d, solid content 8%~12%) is fed into organic slurry by gradient extrusion pretreatment of ultra-high pressure extrusion equipment, and then removed by impurity remover to remove impurities (20t / d), the prepared slurry is transported to a high-temperature cooking tank for cooking, steam (10t / d) is used as an external heat source, and the cooked slurry (90t / d) is separated into solid (12t / d) and liquid ( 74t / d) and oil (4t / d) are separated in three phases, the proposed crude oil is sold outside, and the solid phase is used for black soldier fly breeding; the liquid phase (74t / d) enters the directional fermentation tank, and at the same time, 5% to 10 % acetic acid fermentation bacteria, etc., adjust the pH in the directional fermenter to be ...

Embodiment 3

[0074] see Figure 5 , this embodiment provides a method for preparing a new type of biomass carbon source by enhanced anaerobic fermentation of organic waste, using the system of the present invention, including:

[0075] Kitchen waste (100t / d, solid content 10% to 25%) is fed into the slurry by ultra-high pressure extrusion equipment in a gradient extrusion method, and then removed by the impurity remover to remove impurities (10t / d) , the prepared slurry (90t / d) directly enters the saccharification tank, adds 10% cellulase to the saccharification tank for saccharification, enters the directional fermenter after saccharification, and adds 5% acetic acid fermenting bacteria After fermentation, the fermentation liquid is obtained, and the pH in the directional fermentation tank is adjusted between 4.5 and 6, and the fermentation temperature is 25 to 35°C. After the fermentation liquid is separated and purified by a separation and purification device, the concentrated liquid co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com