Optical film for enhancing reflection and direct type backlight module applying same

A technology of optical film and backlight module, which is applied in the field of optical materials and optical systems, and can solve the problems of affecting display effect, color shift of picture quality, increasing product cost and power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

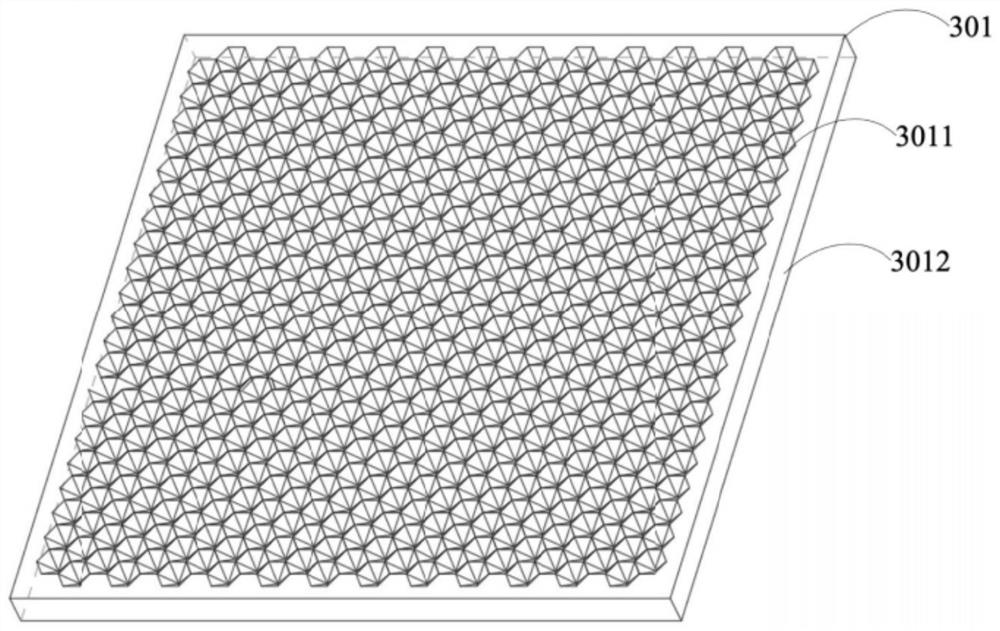

[0046] This embodiment provides an optical film 301 made of polycarbonate, such as image 3 , Figure 4 As shown, the optical film 301 includes a light-emitting side and a light-incident side disposed opposite to each other perpendicular to its thickness direction, a reflective layer 3011 is disposed on the light-emitting side, and a transmissive layer 3012 is disposed on the light-incident side. The surface of the reflective layer 3011 is provided with a plurality of microlens structures that are concave to the inside of the optical film 301. The microlens structures are planar symmetric structures in the shape of hexagonal pyramids, and the size of all the microlens structures is greater than 100 μm. The microlens structure adjoins at least one other microlens structure. In other embodiments, the microlens structure disposed on the reflective layer 3011 may also be other planar symmetric structures, such as a hemispherical structure, a cylindrical structure, a near-conical ...

Embodiment 2

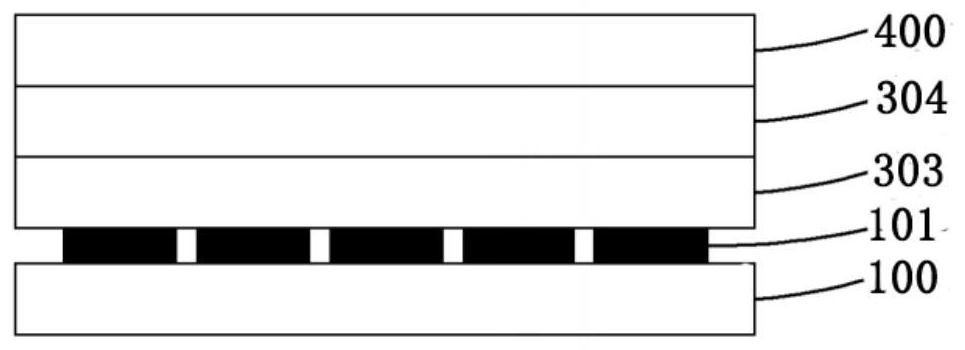

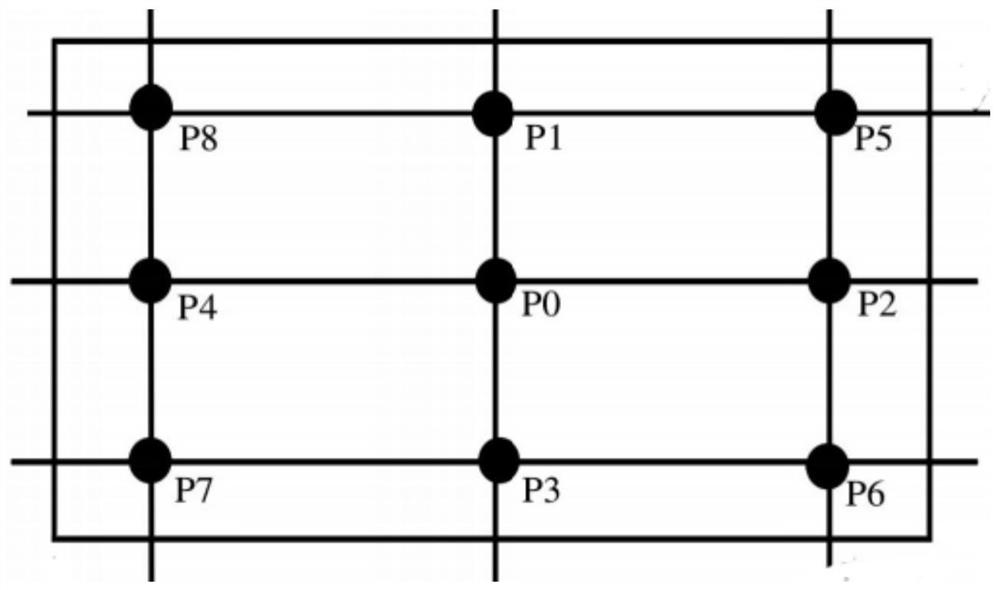

[0054] This embodiment provides a direct-lit backlight device using the optical film 301 provided in Embodiment 1, such as Figure 7 As shown, the direct-lit backlight device further includes a PCB substrate 100 , a reflector 200 and a quantum dot film 303 . A plurality of Mini-LED light sources 101 are installed on the surface of the PCB substrate 100, and the plurality of Mini-LED light sources 101 are arranged periodically. The "periodic arrangement" mentioned here means arranged in a matrix. In this implementation, each Mini-LED - The LED light source 101 comprises a Mini-LED chip. The reflection cover 200 includes a plurality of reflection cup structures with upper and lower openings. In the direct-lit backlight device, the PCB substrate 100, the reflector 200, the optical film 301, and the quantum dot film 303 are arranged sequentially from bottom to top, and each Mini-LED light source 101 is set corresponding to a reflective cup structure. The Mini-LED light source 10...

Embodiment 3

[0060] In the following, only the differences between this embodiment and Embodiment 1 will be described, and the similarities will not be repeated here. This embodiment is based on the optical film structure provided in Example 1, with the ratio of the thickness of the transmissive layer 3012 and the reflective layer 3011 in the optical film as a variable (controlling the thickness of the reflective layer 3011 is constant, by changing the thickness of the transmissive layer 3012 In order to adjust the thickness ratio), different optical films were designed, and the different optical films were assembled with reference to Example 2 in a direct-type backlight device, and the optical performance test was carried out.

[0061] The ratios of the thicknesses of the direct-type backlight device and its optical film of the transmissive layer 3012 to the reflective layer 3011 are respectively: backlight device 1A, transmissive layer: reflective layer = 1:10; backlight device 1B, transm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com