Phase field simulation method for predicting nano alpha twin crystal precipitation and microscopic structure evolution in titanium alloy in local stress state

A microstructure and phase field simulation technology, applied in the field of metallurgical casting, can solve problems such as difficulty in characterizing local stress state, reduce fatigue and creep properties of alloys, and achieve the effect of improving and optimizing mechanical properties and avoiding limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

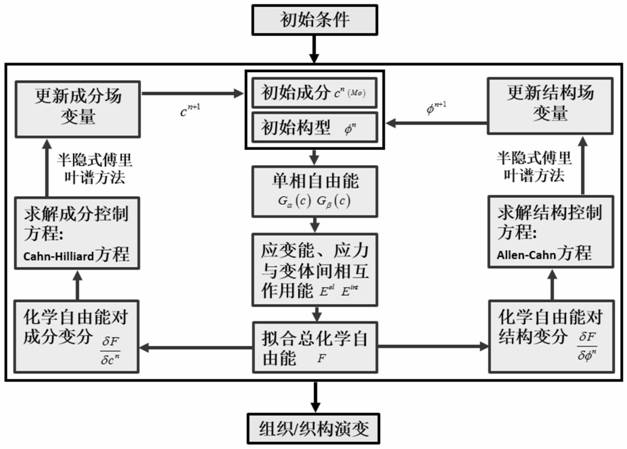

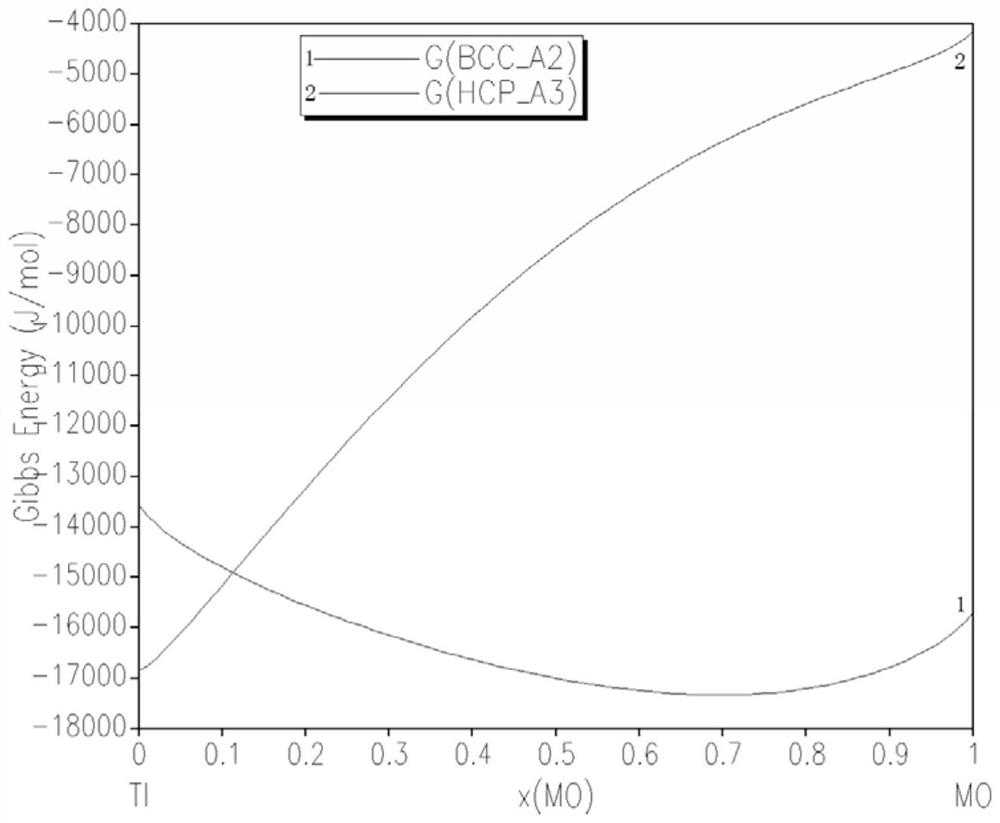

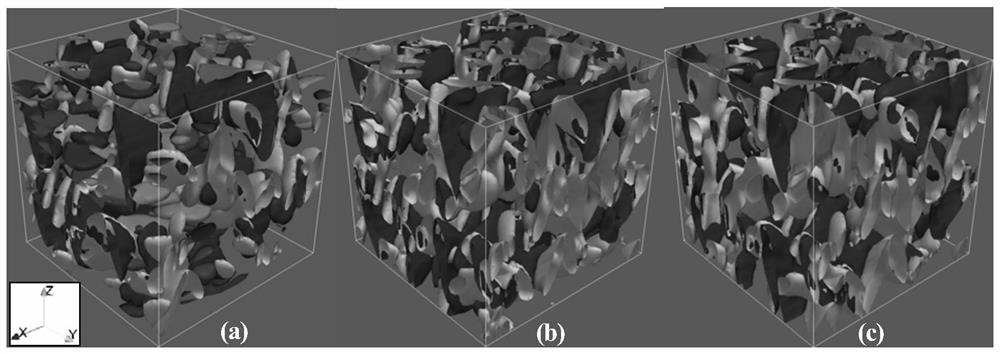

[0064] Such as Figure 6 As shown, the simulation method for predicting the precipitation of nano-α twins and the evolution of microstructure in titanium alloys under external stress is as follows: first, collect the thermodynamic data of the titanium alloy system and the strain parameters of the α-transition phase transformation; then, establish the phase field dynamics Next, input various physical parameters, boundary conditions, interface energy and external stress loads into the model; use Fortran language to write a program to solve the phase field governing equation; visualize the output structure and composition field variables, and statistically Volume fraction of different kinds of α variants, texture strength calculated for tissues under different stress conditions.

[0065] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments.

[0066] Embodiment is exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com