Environment-friendly cultivation bag for camellia oleifera container grafted seedlings

A container grafting seedling and cultivation bag technology, which is applied in cultivation, grafting, application, etc., can solve the problems of no antibacterial performance and water absorption, the plant is vulnerable to insect damage, and poor degradability, so as to increase water absorption and moisture absorption performance, improve Anti-salt stress ability, effect of increasing fat solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

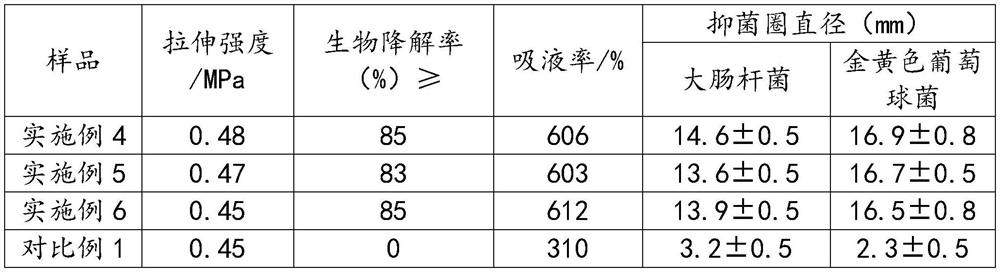

Examples

Embodiment 1

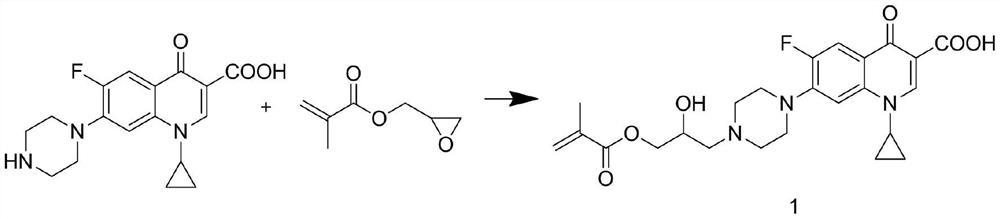

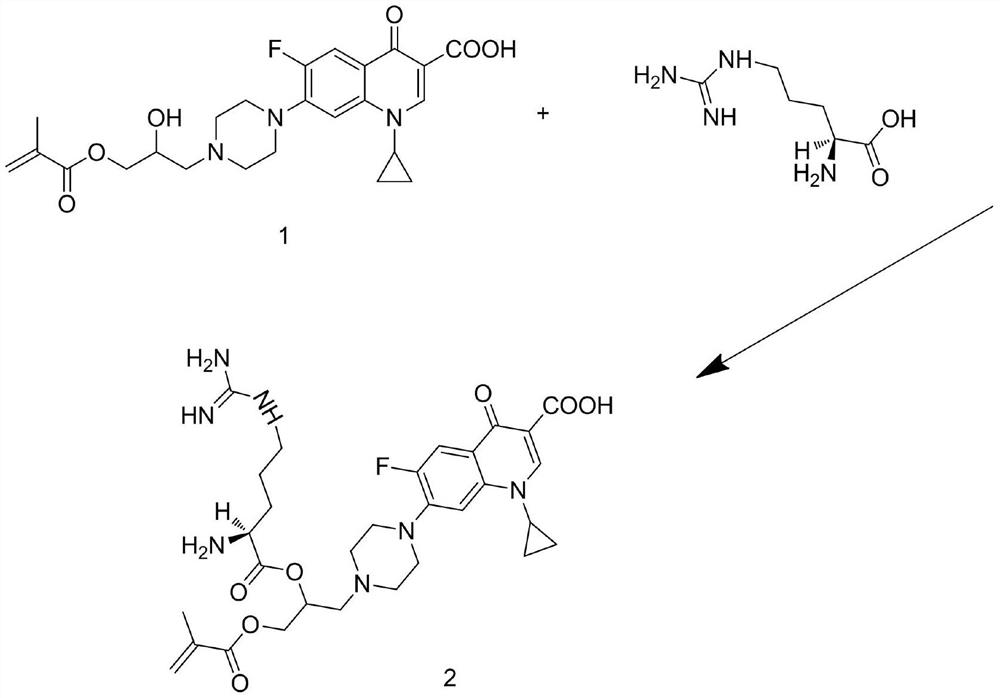

[0027] Modified polypropylene is made of the following steps:

[0028] Step 1, 1 g of cyclopropoxicle, 0.42 ml of methacrylate and 5 ml of dimethylformamide were added to the round bottom flask, and the magnetic force was stirred, and the hydrochloric acid solution of 2 ml concentration of 0.1 mol / L was slowly added dropwise. At 40 ° C, the holding was stirred for 24 h, after cooling to room temperature, filtered, filtered cake was washed 3 times with diethyl ether, and then dried in an oven at 60 ° C to constant weight, resulting in monomer 1;

[0029] Step 2, 5 mmol of monomers 1 and 10 ml of dimethylformamide were added to the reactor, and 10 ml of an aqueous solution of 10 ml of arginine was added to the reaction, and stirred under a rotational speed of 50R / min, 2 ml of concentrated sulfuric acid was added to the reaction kettle. After the dropping is completed, the temperature is warmed to 80 ° C, stirred at the speed of 100 minutes under the temperature of 30 min, cool t...

Embodiment 2

[0032] Modified polypropylene is made of the following steps:

[0033] Step 1, 1 g of cyclopropoxicle, 0.42 ml of methacrylate and 7 ml of dimethylformamide were added to the round bottom flask, and the magnetic force was stirred, and the hydrochloric acid solution of 2 ml of concentration of 0.1 mol / L was slowly added dropwise. After 40 ° C, the holding was stirred for 24 h, after cooling to room temperature, filtration, the filter cake was washed 4 times with diethyl ether, and then dried in an oven at 60 ° C to constant weight, resulting in monomer 1;

[0034] Step 2, 5 mmol 1 and 12 ml of dimethylformamide were added to the reaction kettle, and 10 ml of an aqueous solution of 10 ml of arginine was added to the reaction kettle. After stirring at a rotational speed 50R / min, 2 ml of concentrated sulfuric acid was added to the reaction kettle. After the dropping is completed, the temperature is warmed to 82 ° C, stirred at a speed of 150R / min, and the reaction is stirred at ...

Embodiment 3

[0037] Modified polypropylene is made of the following steps:

[0038] Step 1, 1 g of cyclopropoxicle, 0.42 ml of methacrylate and 8 ml of dimethylformamide were added to the round bottom flask, and the magnetic force was stirred, and the hydrochloric acid solution of 2 ml concentration of 0.1 mol / L was slowly added dropwise. After 40 ° C, the incubation was stirred for 24 h, after cooling to room temperature, filtration, filter cake was washed 5 times with diethyl ether, and then dried in an oven at 60 ° C to constant weight, resulting in monomer 1;

[0039] Step 2, 5 mmol 1 and 13 ml of dimethylformamide were added to the reactor, and 10 ml of an aqueous solution of 10 ml of arginine was added to the reaction kettle. After stirring at a rotational speed 60R / min, 2 ml of concentrated sulfuric acid was added to the reaction kettle. After the dropping is completed, the temperature is warmed to 85 ° C, and the reaction is stirred at a rotational speed of 200R / min, and the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com