TPU film with good cohesiveness and preparation method thereof

A cohesive and inert atmosphere technology, which is applied in the field of TPU film, can solve the problems that the mechanical properties cannot meet the market demand and the general cohesiveness of TPU films, etc., and achieve the effects of excellent mechanical properties, improved application fields, and excellent cohesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

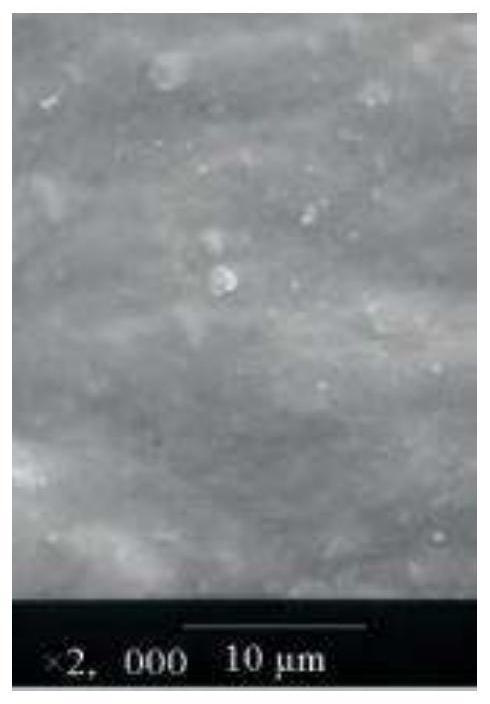

Image

Examples

preparation example Construction

[0058] A method of preparing a TPU film having a good adhesive, including the following steps:

[0059] (1) Doped nano-dioxide particles, modified carbon nanotubes are added to the mixer for stirring, and then dried in the drying tank to give mixed particles;

[0060] (2) The mixed particles are mixed with TPU particles in the reaction vessel, and the reaction kettle temperature range is provided to 168-172, and the reaction reaction is carried out at a temperature of 500 r / min, and the reaction time is 7-8 hours. After the reaction is completed, it is discharged. To get an intermediate;

[0061] (3) Adding an intermediate, plasticizer, lubricant, corn fibrous, compatible agent, and amino silane coupling agent to a twin screw extruder, molten mixing, resulting in a mixture;

[0062] (4) Add the mixture to the casting machine, and then passes to the casting roller roller surface, forming a film, and a pressure is applied to the film, so that the film is flatly attached to the rol...

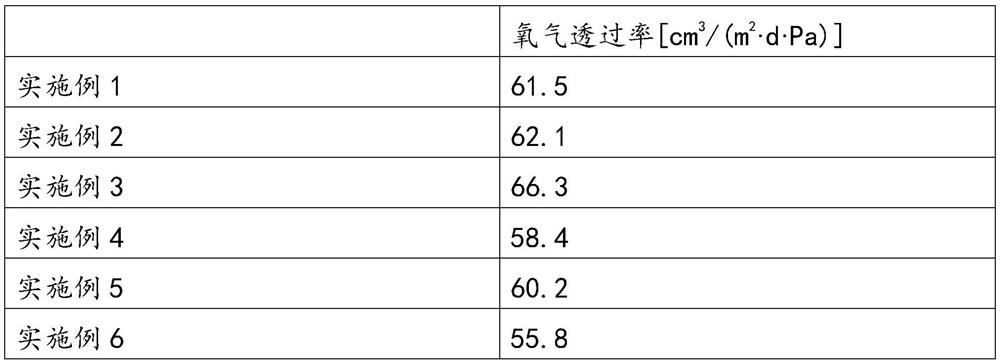

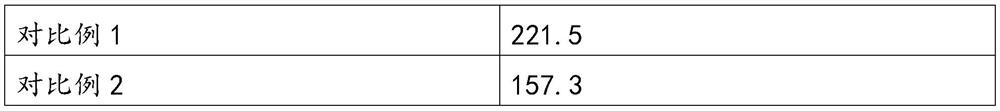

Embodiment 1

[0065] A TPU film having a good adhesive, is made of a component of the following components: TPU particles 88, plasticizers 4, lubricant 1, filler 22, corn fibrous glue 12, compatible agent 1, amino silane coupling Division 1; the filler is formed by mixing nano-dioxide particles, modified carbon nanotubes in a mass ratio of 1: 5. The preparation method of doped nano-dioxide particles is: ammonium polyavantate, ammonium molybdate is added to the stirred tank, stirred at 500 r / min for 30 min, then in an inert atmosphere, heated to 385 At ° C, stirring was stirred for 40 min, then cooled to 220 ° C, and then heated for 1 hour, then heated to 440 ° C, heat premium for 30 min, and then naturally cooled to room temperature, i.e., doped nano-dioxide particles. The inert atmosphere is an argon atmosphere. The modified carbon nanotube preparation method is: uniformly dispersed carbon nanotubes into toluene to obtain a carbon nanotube dispersion; heating carbon nanotube dispersion tempe...

Embodiment 2

[0067] A TPU film having a good adhesive, is made of a component of the following components: TPU particles 92, plasticizer 6, lubricant 2, filler 26, corn fibrous glue 18, compatible agent 4, amino silane coupling Division 4; the filler is mixed by doping nano-dioxide particles, modified carbon nanotubes in a mass ratio of 1: 5. The preparation method of doped nano-dioxide particles is to add polyvantadanate and ammonium molybdate to the stirrer, stirred at a temperature of 500 r / min for 30 min, and then heated to 390 in an inert atmosphere ° C, stirring was stirred for 40 min, then cooled to 230 ° C, followed by holding for 1 hour, then heated to 460 ° C, holding up for 30 min, then naturally cooled to room temperature, i.e., doped nano-nanowalline dioxide particles. The inert atmosphere is an argon atmosphere. The modified carbon nanotube preparation method is: uniformly dispersed carbon nanotubes into toluene to obtain a carbon nanotube dispersion; heating the carbon nanotub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com