Preparation method of silane modified water-based acrylic coating

A water-based acrylic and silane modification technology, applied in the direction of coating, can solve the problems of low adhesion, weak mechanical properties, poor water resistance, etc., and achieve the effect of improving adhesion, improving wear resistance and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare a kind of silane modified waterborne acrylic paint preparation method, its method is as follows:

[0039] 1) Water-based acrylic emulsion: 60 parts; calcium carbonate: 36 parts; surfactant stearic acid: 2 parts; defoamer polydimethylsiloxane: 1 part; leveling agent polyether modified polysiloxane : 1 part; Stir to mix evenly;

[0040] 2) The pH value of the coating described in the above step 1 is adjusted to be acidic 4;

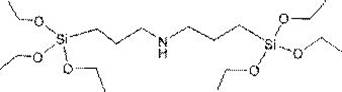

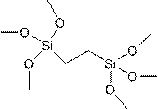

[0041] 3) Mix 3 parts of silane crosslinking agent bis-(3-(triethoxysilane)propyl)-disulfide into the above coating and stir evenly;

[0042] 4) Carry out construction and complete the construction within 60 minutes.

Embodiment 2

[0044] Prepare a kind of silane modified waterborne acrylic paint preparation method, its method is as follows:

[0045] 1) Water-based acrylic emulsion: 80 parts; titanium dioxide: 18 parts; surfactant sodium dodecylbenzene sulfonate: 1 part; defoamer polyoxyethylene polyoxypropanolamine ether: 0.5 parts; Ether-modified polysiloxane: 0.5 parts; stir and mix evenly;

[0046] 2) The pH value of the coating described in the above step 1 is adjusted to be neutral 7;

[0047] 3) Mix 8 parts of silane crosslinking agent bis(3-triethoxysilylpropyl)amine into the above coating and stir evenly;

[0048] 4) Carry out construction and complete the construction within 15 minutes.

Embodiment 3

[0050] Prepare a kind of silane modified waterborne acrylic paint preparation method, its method is as follows:

[0051] 1) Water-based acrylic emulsion: 70 parts; silicon dioxide: 27 parts; surfactant cetyltrimethylammonium bromide: 1.5 parts; defoamer polyoxypropylene polyoxyethylene glyceryl ether: 0.75 parts; leveling Agent polyether modified polysiloxane: 0.75 parts; Stir and mix evenly;

[0052] 2) Adjust the pH value of the coating described in the above step 1 to be alkaline to 10;

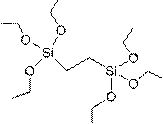

[0053] 3) Mix 5 parts of silane crosslinking agent 1, 2-bis(triethoxysilyl)ethane into the above coating, and stir evenly;

[0054] 4) Carry out construction and complete the construction within 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com