Sensor monocrystalline silicon etching device

An etching device and technology of single crystal silicon, applied in the field of sensors, can solve problems such as inability to adjust, fixed distance, uneven etching of sensor single crystal silicon, etc., and achieve the effect of increased loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

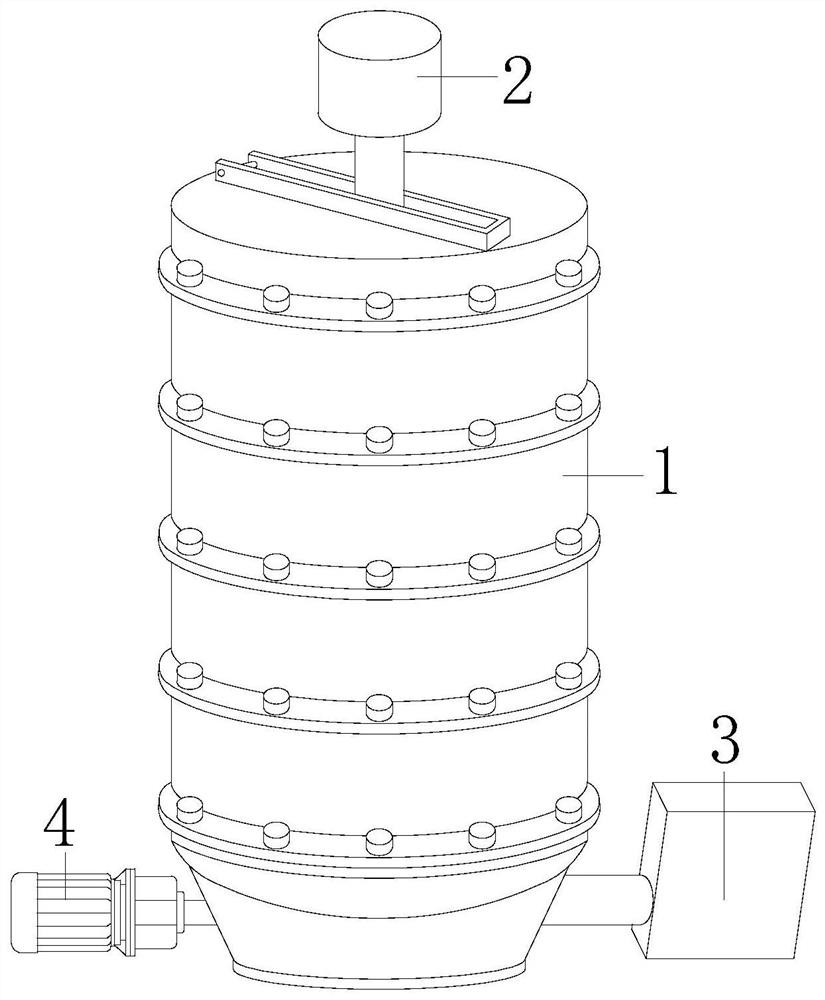

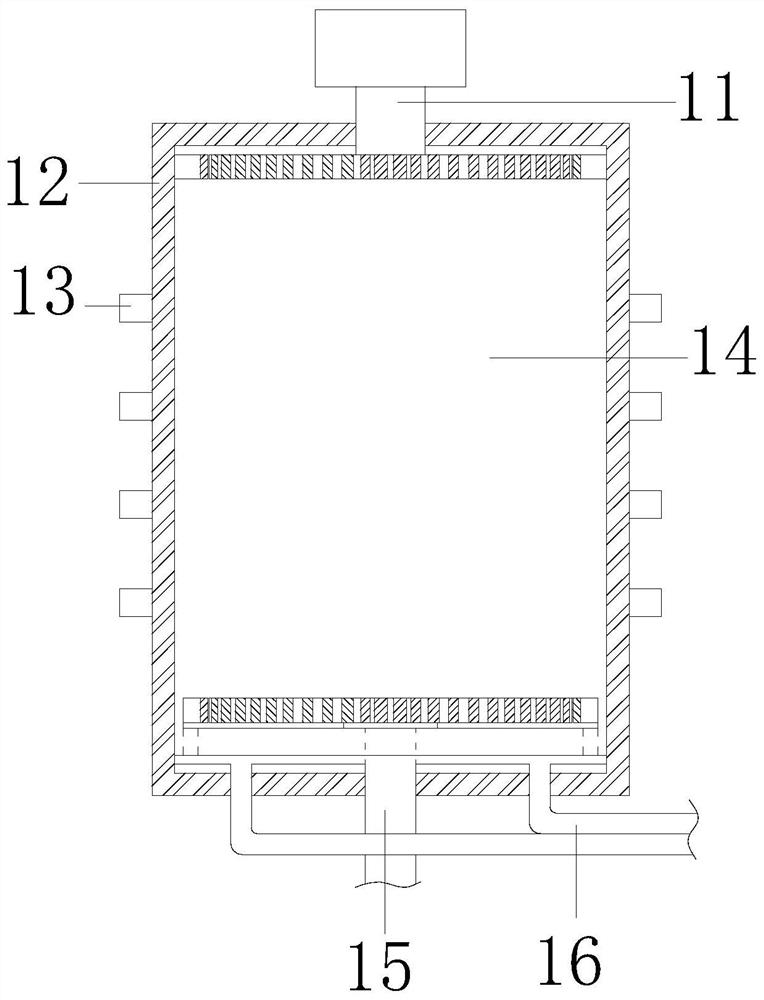

[0024] as attached figure 1 To attach Figure 5 Shown:

[0025] The present invention provides a single crystal silicon etching device for sensors, the structure of which includes an etching mechanism 1, a gas source chamber 2, a vacuum pump 3, and a drive motor 4. The lower end of the gas source chamber 2 is flange-connected to the upper end of the etching mechanism 1, The vacuum pump 3 is arranged on the right side below the air source chamber 2, the driving motor 4 is arranged on the left side below the air source chamber 2, and the etching mechanism 1 is composed of an air supply port 11, a housing 12, an electromagnetic coil 13, and a reaction chamber. The mechanism 14, the first rotating shaft 15, and the suction pipe 16 are composed of the lower end of the air delivery port 11 and the upper end of the housing 12 by welding, the electromagnetic coil 13 is connected with the housing 12 by bolts, and the reaction chamber mechanism 14 is located at the air delivery port ...

Embodiment 2

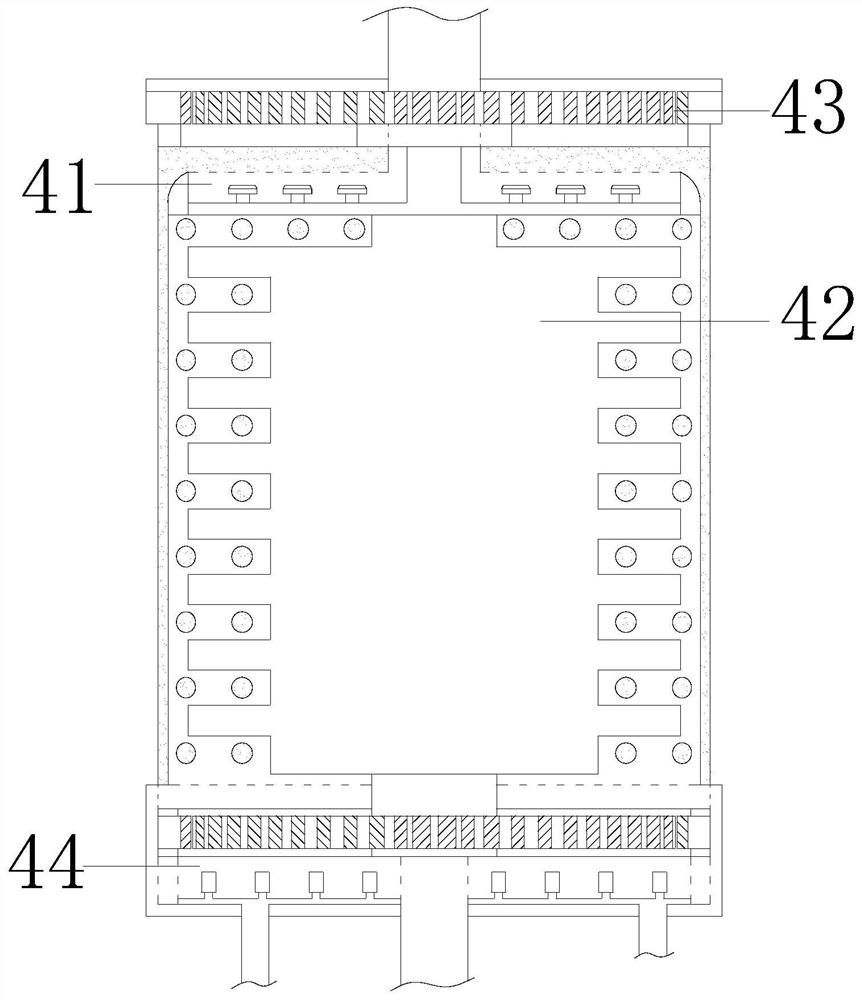

[0032] as attached Figure 6 To attach Figure 7 Shown:

[0033] Wherein, the air suction mechanism 44 is composed of a transmission gear 441, a filter screen 442, an air suction chamber 443, an air suction head mechanism 444, and an air suction pipe 445. The filter screen 442 is arranged on the left and right sides of the transmission gear 441 lower end, so The upper end of the suction chamber 443 is welded to the connecting rod at the lower end of the transmission gear 441, the suction head mechanism 444 is arranged above the inner bottom plate of the suction chamber 443, and the lower end of the suction head mechanism 444 is welded to the upper section of the suction pipe 445, The suction head mechanism 444 is located at the lower end of the housing 12, and the filter screen 442 has properties such as acid resistance, alkali resistance, temperature resistance, and wear resistance, and is used to filter the moisture in the gas so that it enters the suction chamber 443. The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com