Quartz glass crucible, method for producing silicon single crystal using same, method for measuring infrared transmittance of quartz glass crucible, and method for manufacturing quartz glass crucible

A quartz glass crucible, infrared transmission technology, applied in transmittance measurement, glass manufacturing equipment, glass molding and other directions, can solve the problems of transmittance decrease and transmittance increase, and achieve the effect of improving the manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107]

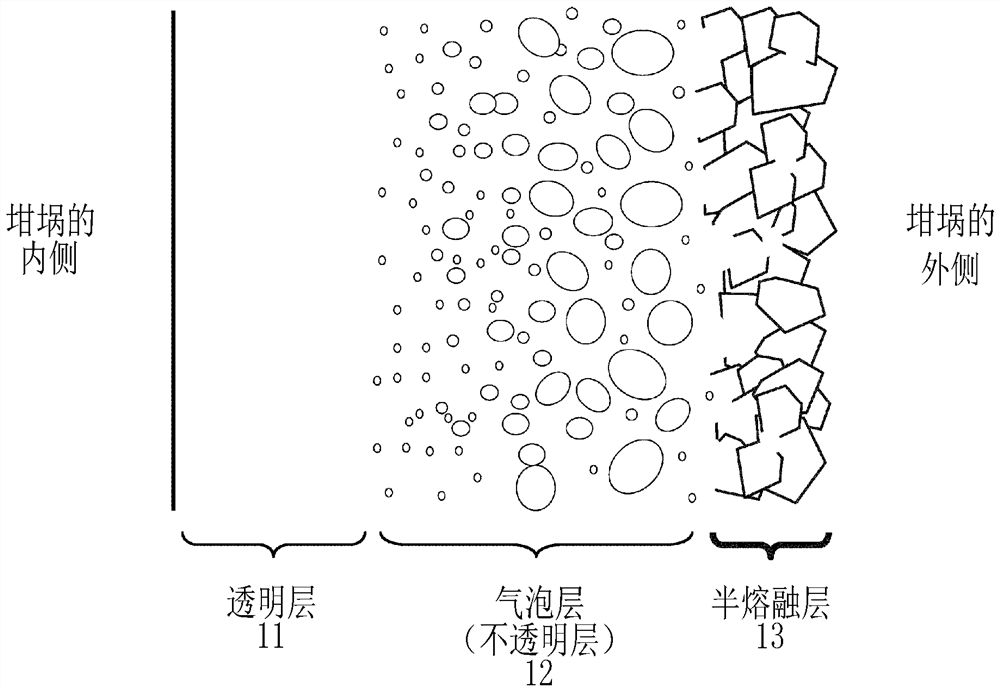

[0108] The influence of the semi-molten layer on the infrared transmittance of the crucible was investigated. In this investigation, a quartz glass crucible with a diameter of 800 mm (32 inches) was first prepared, and a crucible piece about 30 mm square was cut out from its side wall. The semi-fused layer on the outer surface of the crucible piece sample was not polished in any way, according to JIS B0601 As a result of measuring the surface roughness of the outer surface according to the -2001 standard, the arithmetic mean roughness Ra was 30 μm.

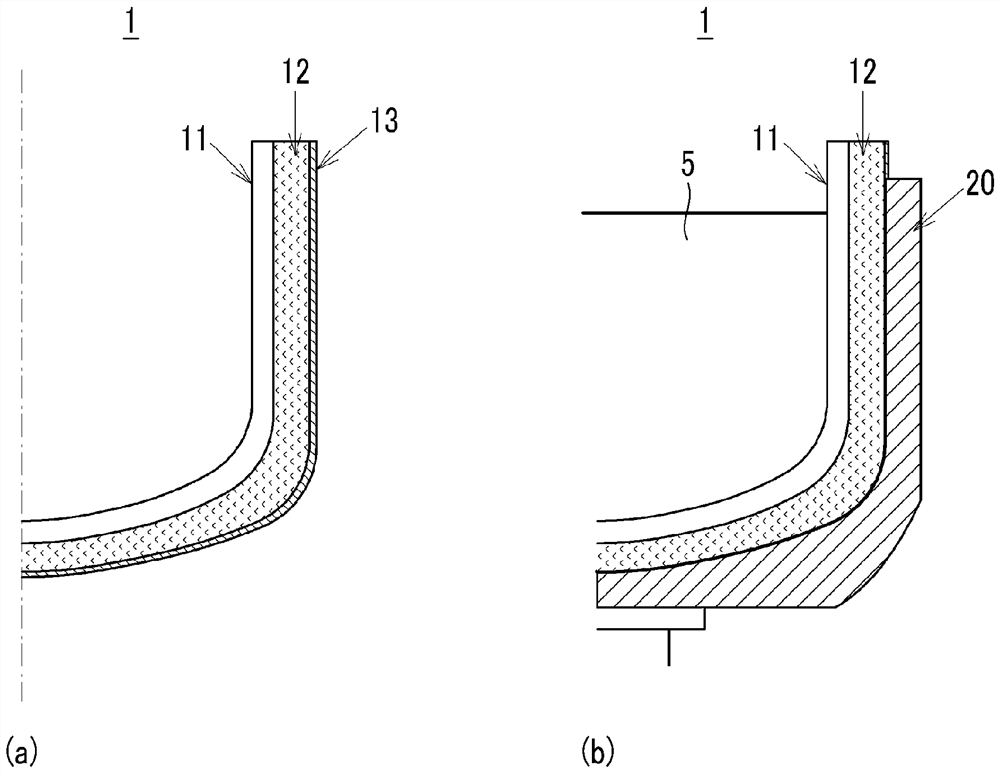

[0109] Secondly, the infrared transmittance of the crucible piece sample was measured. In the measurement of infrared transmittance, a laser power meter (light receiving device) with a diameter of 22 mm in the light receiving part is installed at a position 43 mm away from the infrared lamp with a wavelength of 0.5 to 3.5 μm and a peak wavelength of 1.0 μm, and a crucible piece sample of about 30 mm square is placed in ...

Embodiment 2

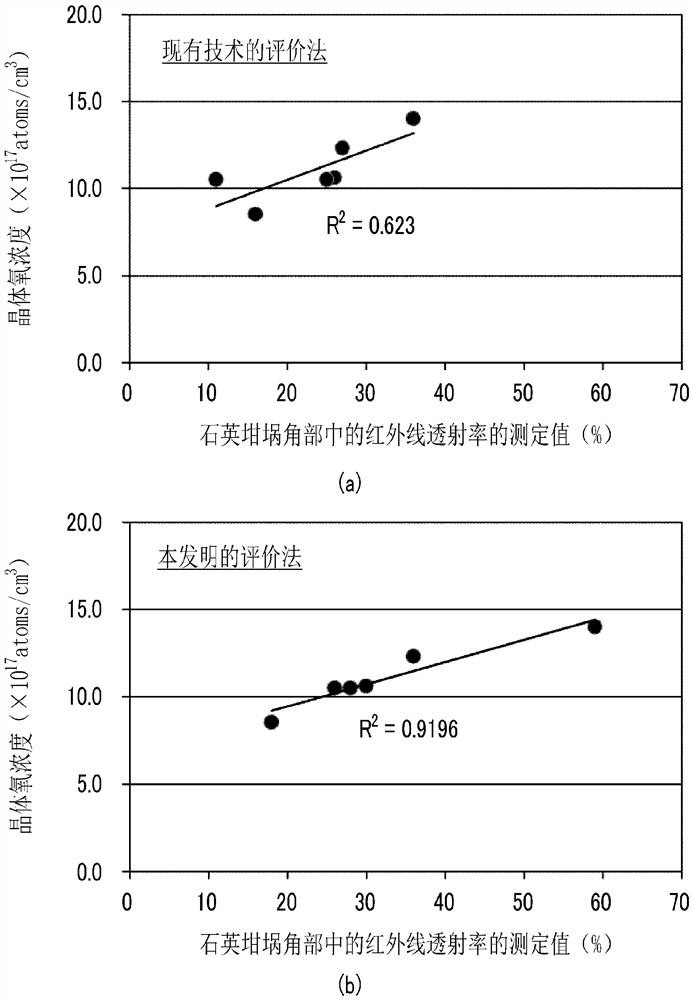

[0118] The infrared transmittances of the side walls, corners, and bottom of the quartz glass crucible sample #2 according to Example 2 were 70%, 25%, and 50%, respectively. The oxygen concentration in the single crystal silicon pulled using this crucible sample #2 was 9×10 17 ~12×10 17 atoms / cm 3 In the range of , it becomes a particularly low value, and there is no dislocation in the single crystal.

Embodiment 3

[0119] The infrared transmittances of the side walls, corners, and bottom of the quartz glass crucible sample #3 according to Example 3 were 56%, 33%, and 36%, respectively. The oxygen concentration in the single crystal silicon pulled using this crucible sample #3 was 9×10 17 ~12×10 17 atoms / cm 3 In the range of , it becomes a particularly low value, and there is no dislocation in the single crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arithmetic mean roughness | aaaaa | aaaaa |

| Arithmetic mean roughness | aaaaa | aaaaa |

| Arithmetic mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com