Plastic plant culture medium and preparation method thereof

A cultivation substrate and plasticity technology, applied in the field of plastic plant cultivation substrate and its preparation, can solve the problems of serious negative nutrition of rivers and groundwater, difficulty in ensuring nutrient content, non-renewable raw materials, etc., so as to increase ventilation and water permeability and improve agricultural energy. The utilization rate of resources and the effect of inhibiting the reproduction of miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

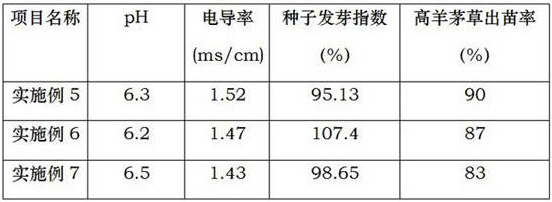

Examples

Embodiment 1

[0020] Embodiment 1: a kind of plastic plant cultivation matrix, comprises the raw material of following mass percentage: 20% compost product, 0.1% microbial inoculant, 2% rice husk, 20% peat soil, 2% perlite, 2% % vermiculite, 5% insect sand manure, 0.2% bacteriostat, 0.2% growth regulator. The microbial agent is Bacillus subtilis; the growth regulator is a mixture of paclobutrazol, ABT rooting powder, forchlorfenuron, diethyl ethyl, and sodium nitrophenolate; paclobutrazol, ABT rooting powder, forchlorfenuron, diethyl ethyl, The mass ratio of sodium nitrophenolate is 0.5:1:0.5:0.5:0.5:1.

Embodiment 2

[0021] Embodiment 2: a kind of plasticity plant cultivation matrix, comprises the raw material of following mass percentage: 30% compost product, 0.3% microbial bacterial agent, 6% rice husk, 25% peat soil, 5% perlite, 5% % of vermiculite, 12% of insect sand manure, 1% of antibacterial agent, and 1% of growth regulator. The microbial agent is jelly-like Bacillus; the growth regulator is a mixture of paclobutrazol, ABT rooting powder, forchlorfenuron, diethyl ethyl, and sodium dinitrophenolate; paclobutrazol, ABT rooting powder, forchlorfenuron, diethyl ethyl , The mass ratio of sodium nitrophenolate is 0.8:0.8:0.1:0.8:0.1:0.7.

Embodiment 3

[0022] Embodiment 3: a kind of plasticity plant cultivation matrix, comprises the raw material of following mass percentage: 40% compost product, 0.5% microbial inoculant, 10% rice husk, 30% peat soil, 10% perlite, 10% % vermiculite, 20% insect sand manure, 2% bacteriostatic agent, and 2% growth regulator. The microbial agent is Bacillus megaterium; the growth regulator is a mixture of paclobutrazol, ABT rooting powder, forchlorfenuron, diethyl diethyl ethyl, and sodium nitrophenolate; The mass ratio of sodium nitrophenolate is 0.1:0.5:0.8:1:0.8:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com