Production equipment and method thereof of internal and external type high-strength high-conductivity wear-resistant copper-steel composite contact wire

A composite contact and production equipment technology, applied in the field of wire rods, can solve the problems of large wear, shorten the service life of the contact wire, and limit the improvement range, and achieve the effects of strengthening the firmness, saving the electrical conductivity and increasing the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

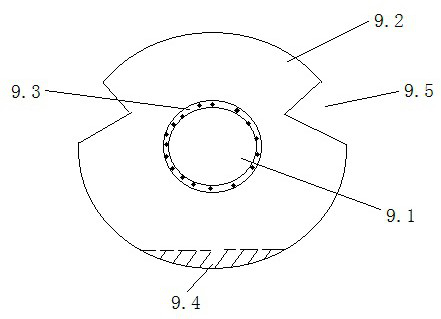

[0031] see Figure 1-2 , figure 1 A schematic diagram of the production equipment for an internal and external high-strength, high-conductivity and wear-resistant copper-steel composite contact wire is drawn. As shown in the figure, the production equipment of internal and external high-strength, high-conductivity and wear-resistant copper-steel composite contact wires involved in the present invention includes a first mold 5, a circulating cooling system 6 and a finishing mold 7; the first mold 5 includes an injection section and In the cooling section, the injection section is provided with five injection ports, respectively injecting steel core 1, copper water 2, copper-magnesium alloy furnace water 3 and copper-steel mixed furnace water 4, and the cooling section is provided with a circulating cooling system 6.

[0032] The first mold 5 is provided with a cylindrical steel core cavity for placing the steel core 1; the outer ring of the steel core cavity is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com