High-concentration organic industrial wastewater treatment and cyclic utilization integrated system

An industrial wastewater and integrated system technology, applied in the direction of water/sewage multi-stage treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., can solve the problem of sludge swelling and loss, the impact of air environment on human health, water distribution points Problems such as blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

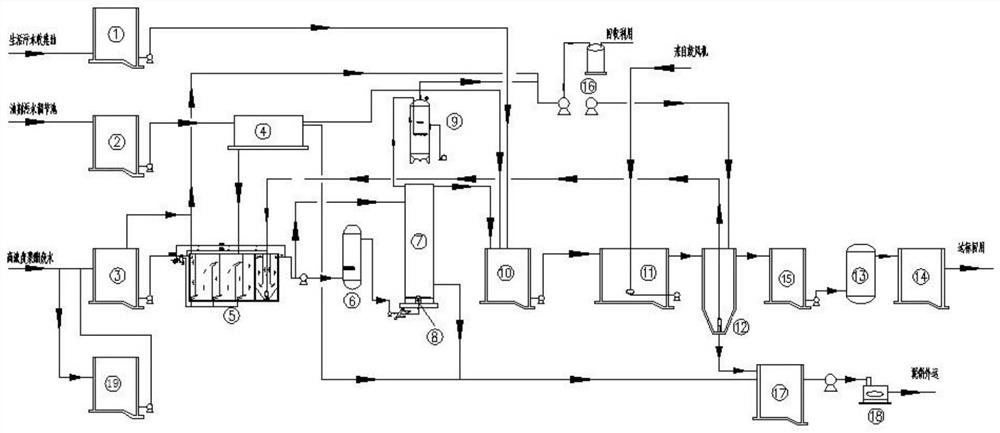

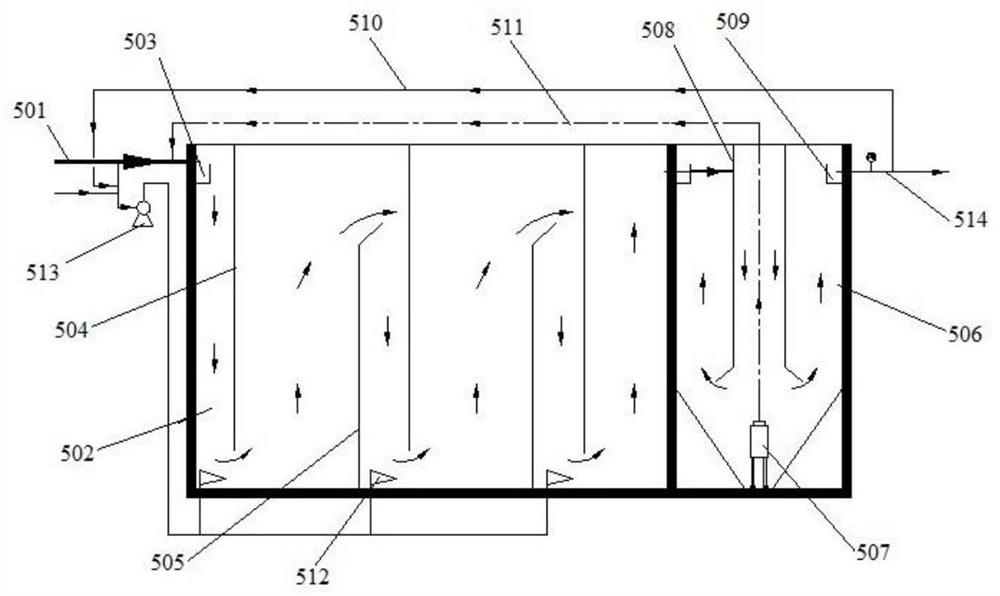

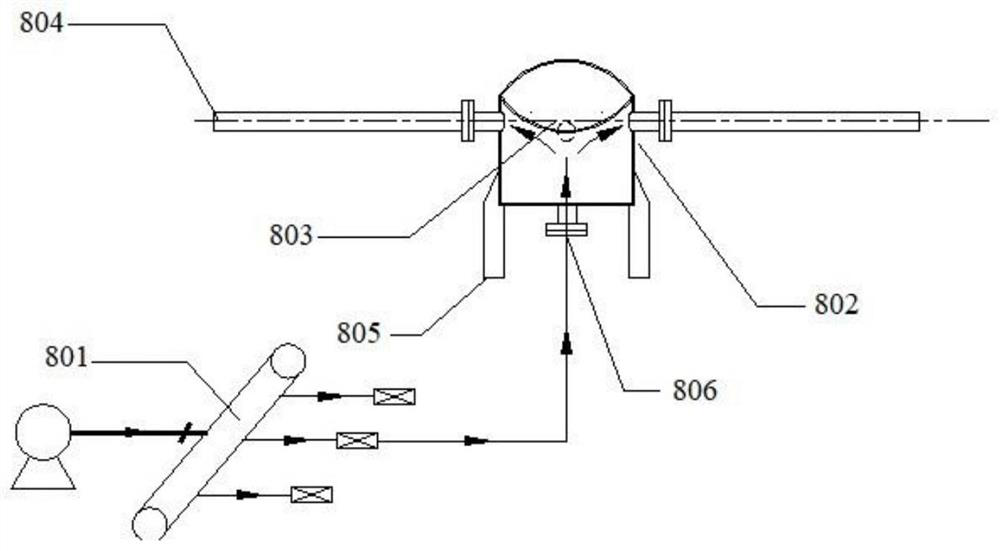

[0035] Such as figure 1 As shown, an integrated system for the treatment and recycling of high-concentration organic industrial wastewater, including a high-concentration sewage regulating pool 3, an oily sewage regulating pool 2, a domestic and ground washing sewage collection pool 1, an accident sewage pool 19, and emulsified oil separation Device 4, homogeneous hydrolysis tank 5, high-efficiency anaerobic reactor 7, comprehensive sewage regulating tank 10, high multiplier biological treatment tank 11, sedimentation tank 12, intermediate tank 15, filter 13, sludge tank 17 and monitoring discharge tank 14 , the high-concentration sewage regulating pool 3 is connected to the comprehensive sewage regulating pond 10 through the homogeneous hydrolysis pond 5 and the high-efficiency anaerobic reactor 7, and the described oily sewage regulating po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com