Pervious concrete reinforcing agent

A permeable concrete and reinforcing agent technology, applied in the field of concrete, can solve the problems of loss of permeable concrete, limited improvement of compressive strength of permeable concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment discloses a reinforcing agent for permeable concrete, which is prepared by the following steps:

[0049] Step 1), adding water and surfactant accounting for 20% of the total mass of water into the mixer and stirring for 3 minutes at a speed of 60 r / min to obtain the first mixed solution;

[0050] Step 2), add remaining water, calcium nitrate, calcium nitrite, ferrous chloride, sodium nitrate and auxiliary agent into the mixer and stir for 5min, the stirring speed is 80r / min, to obtain the second mixed solution;

[0051] Step 3), add microsilica fume to the mixer and continue stirring for 10 minutes at a speed of 120r / min to obtain a reinforcing agent for permeable concrete.

Embodiment 2

[0053] This embodiment discloses a reinforcing agent for permeable concrete, which is prepared by the following steps:

[0054] Step 1), adding water and surfactant accounting for 25% of the total mass of water into the mixer and stirring for 4 minutes at a speed of 70 r / min to obtain the first mixed solution;

[0055] Step 2), add remaining water, calcium nitrate, calcium nitrite, ferrous chloride, sodium nitrate and auxiliary agent into the mixer and stir for 8min, stirring speed 100r / min, to obtain the second mixed solution;

[0056] Step 3), add microsilica fume to the mixer and continue stirring for 13 minutes at a speed of 135r / min to obtain a reinforcing agent for permeable concrete.

Embodiment 3

[0058] This embodiment discloses a reinforcing agent for permeable concrete, which is prepared by the following steps:

[0059] Step 1), adding water and surfactant accounting for 30% of the total mass of water into the mixer and stirring for 5 minutes at a speed of 80 r / min to obtain the first mixed solution;

[0060] Step 2), adding remaining water, calcium nitrate, calcium nitrite, ferrous chloride, sodium nitrate and additives into the mixer and stirring for 10min, stirring speed 120r / min, to obtain the second mixed solution;

[0061] Step 3), add microsilica fume to the mixer and continue stirring for 15 minutes at a speed of 150r / min to obtain a reinforcing agent for permeable concrete.

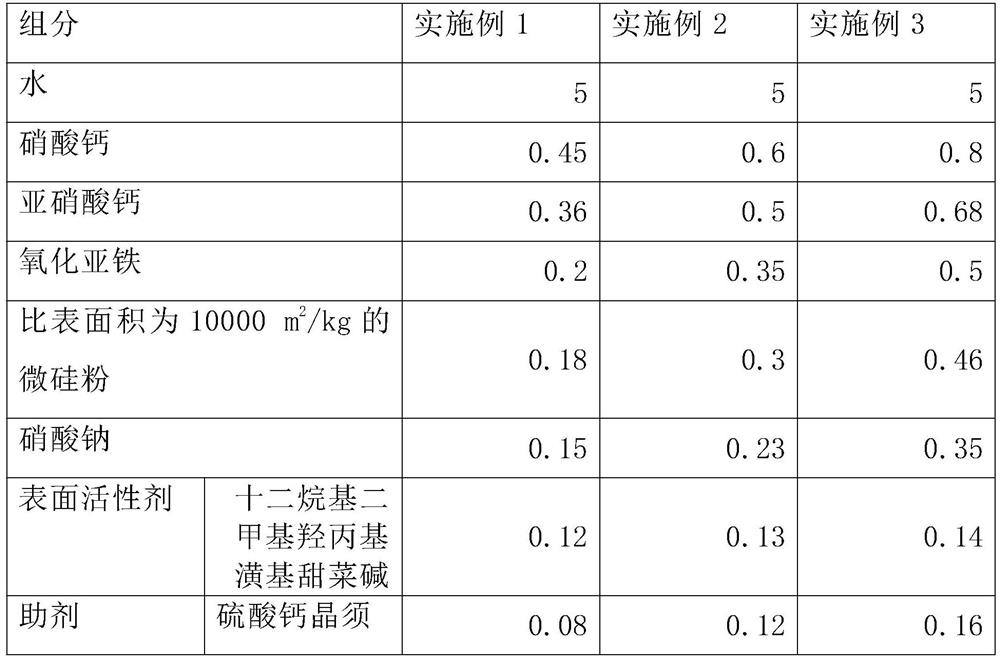

[0062] The component input amount of embodiment 1-3 is shown in Table 1, unit: Kg.

[0063] Table 1

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap