Modifying and flooding agent and method for improving plugging efficiency of polymer microspheres

A technology of polymer and displacement agent, applied in chemical instruments and methods, drilling composition, etc., can solve the problems of limited liquid flow diversion effect and reduced plugging efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

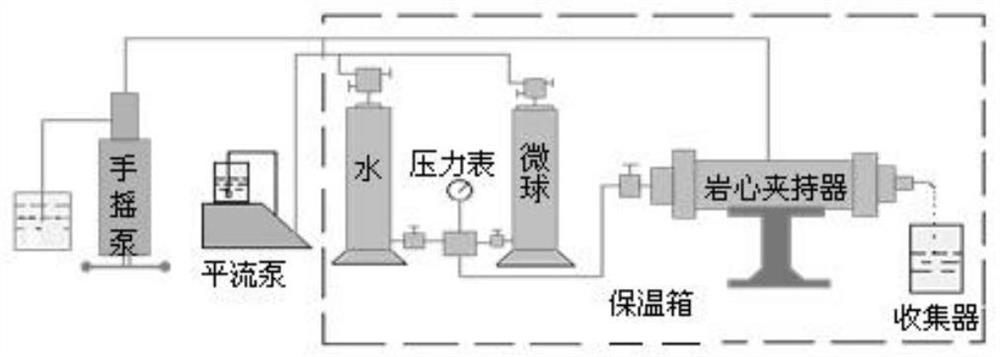

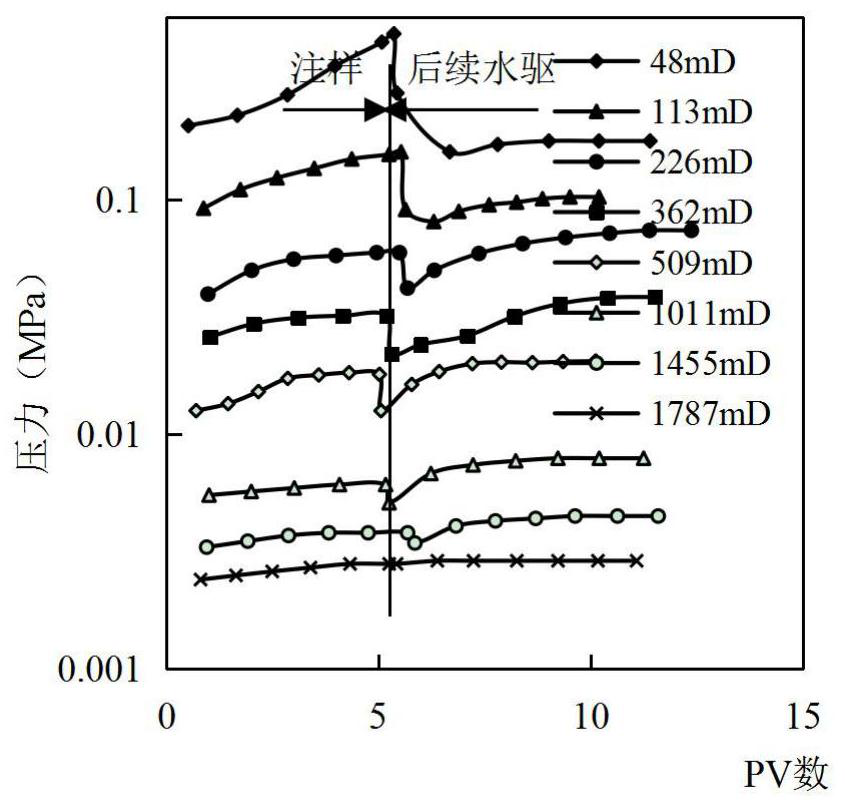

Method used

Image

Examples

preparation example Construction

[0035] In the present invention, the emulsion of the crosslinking agent is a water-in-oil emulsion with a crosslinking agent prepared by mixing an oil phase obtained. In the present invention, the preferred method for preparing the emulsion of the crosslinking agent comprises the steps of:

[0036] 1) mixing the emulsifier with the oil phase to obtain an emulsion;

[0037] 2) the step of mixing the emulsion obtained in 1) with a crosslinking agent, a crosslinking agent to give an emulsion.

[0038] The present invention is preferably mixed with the oil phase emulsifier to obtain an emulsion.

[0039] In the present invention, the emulsifier is preferably used in an amount of 17.8 - 19.4% by mass of the oil phase, and more preferably 18 to 19% by mass of an oil phase; the kind of the emulsifier is preferably from Span-60 and Tween-60 in at least one, and more preferably from Span-60 and Tween-60; when the emulsifier is Span-60 and Tween-60, Span-60 and the mass of Tween-60 or 9:1 i...

Embodiment 1

[0051] Flooding agent prepared by the following method:

[0052] (1) The solids content of 24.5% polyacrylamide microspheres are mixed with the test water, to give a concentration of 3000mg / L solution of polymeric microspheres;

[0053] Wherein the microspheres polyacrylamide water-in-oil emulsion; water injection test water QHD32-6 Bohai oilfield simulation, the water quality analysis results shown in Table 1;

[0054] Table 1 Water quality analysis

[0055]

[0056] (2) the step (1) to give a solution of polymeric microspheres with a crosslinking agent an organic chromium (Cr 3+ Mixing an amount of 1.2%) emulsion, to obtain flooding agent;

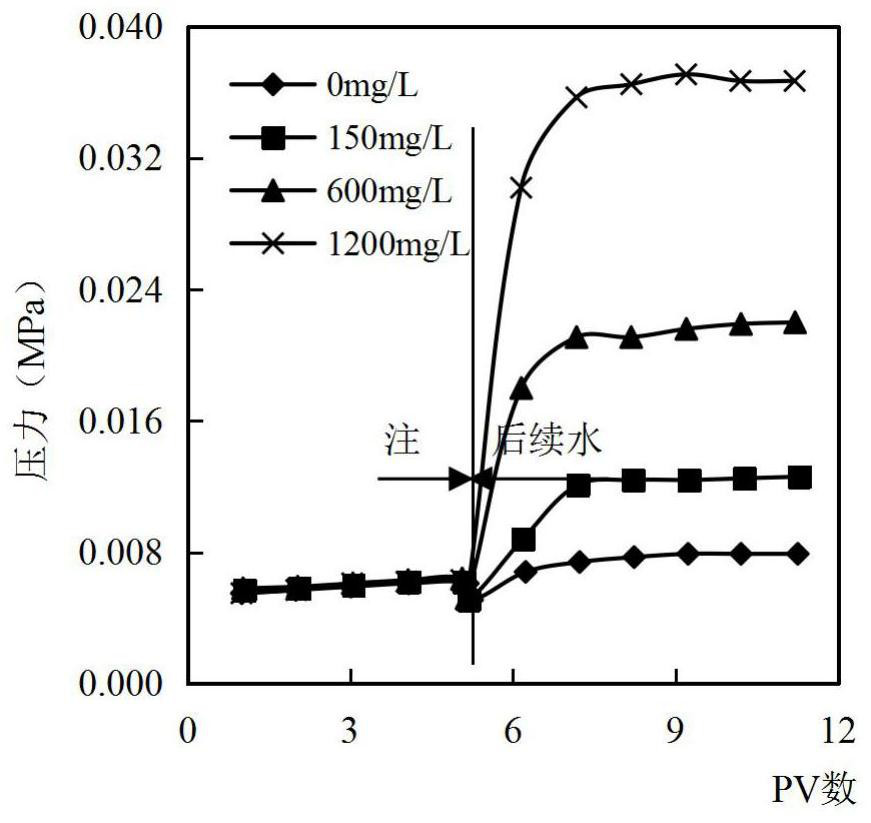

[0057] Wherein the concentration of the mixed flooding agent crosslinking agent is preferably 150mg / L; crosslinker emulsion water-in-oil emulsion with an oil phase prepared by mixing a crosslinking agent obtained in the following steps:

[0058] 1) Tween-60, Span-60 surfactant and liquid paraffin to obtain an emulsion;

[0059] Wherein...

Embodiment 2

[0062] The embodiment of Example 1, Step (2) adjusting the concentration of displacement agent in the crosslinking agent was changed to 600mg / L, ceteris paribus.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com