Transparent conductive film and preparation method and application thereof

A technology of transparent conductive film and transparent substrate, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., and can solve the problems of silver nanowire vulcanization and silver ion migration inhibition effect are not significant, environmental pollution, cost Increase and other issues, to achieve one-dimensional morphology enhancement, improve anti-sulfurization, anti-silver ion migration, and erosion enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

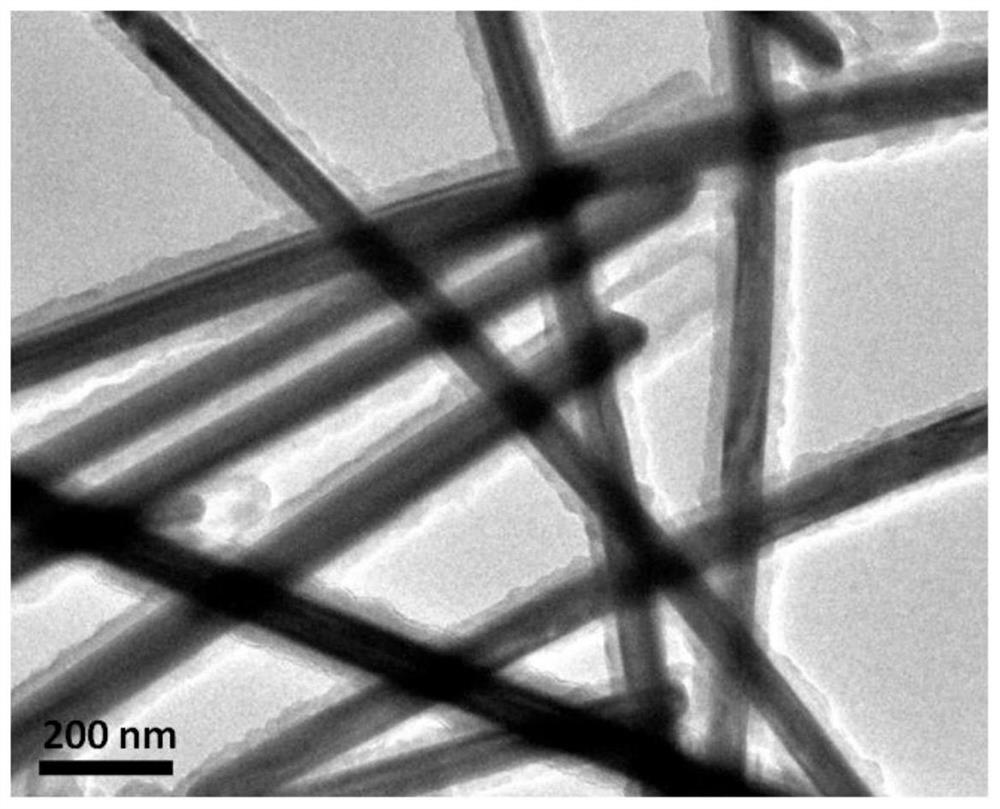

[0033] First, use a wire rod to coat the silver nanowire dispersion in isopropanol on the PET surface, and dry it at 80°C for 5 minutes to evaporate the solvent; then, scrape-coat the tetraethyl orthosilicate on the surface of the silver nanowire network, and then soak it in a 60°C In an aqueous sodium hydroxide solution with a pH of 10, keep warm for 30 minutes; finally, dry to obtain a silver nanowire transparent conductive film. Tested by transmission electron microscopy, such as figure 1 As shown, the surface of silver nanowires can form a silica shell. Hydrogen sulfide treatment for 500 hours, the change in the square resistance of the conductive film is 0.2%; 30V DC voltage treatment for 500 hours, the change in the square resistance of the conductive film is 0.5%; 10% hydrochloric acid solution treatment for 1000 hours, the change in the square resistance of the conductive film is 0.7%; 10% hydrogen Sodium oxide solution treatment for 1000 hours, the change in square r...

Embodiment 2

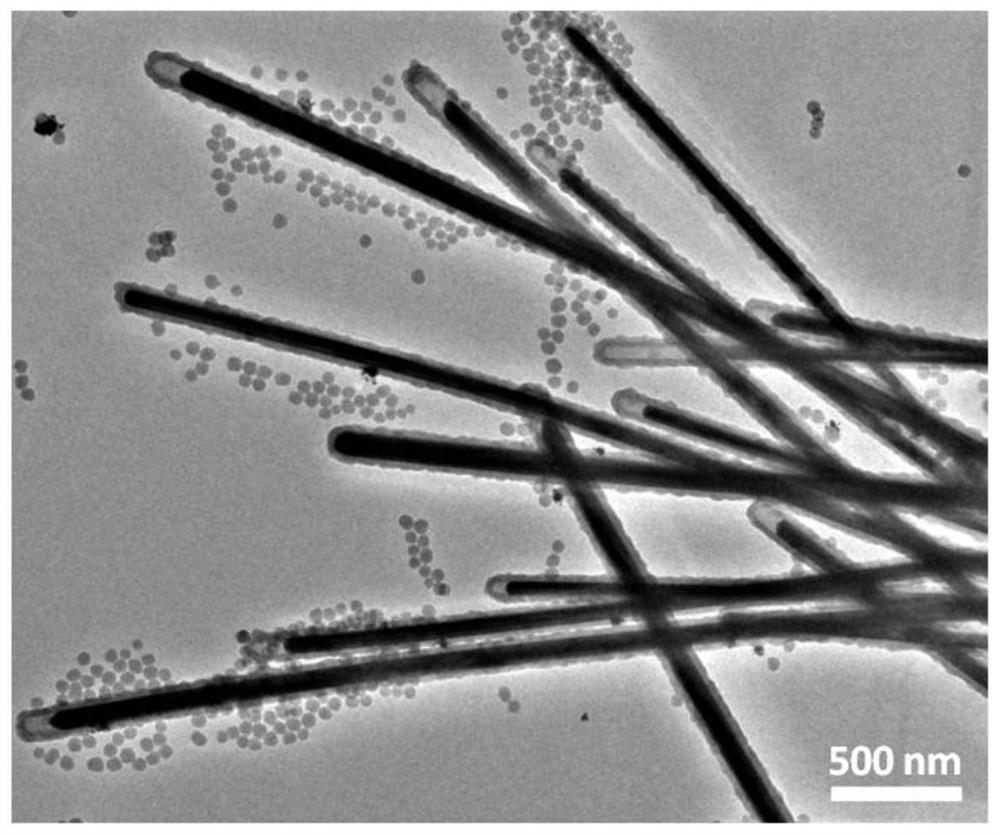

[0035] The silver nanowire transparent conductive film was prepared in the same manner as in Example 1 except that the pH of the aqueous sodium hydroxide solution was 12. Tested by transmission electron microscopy, such as figure 2 As shown, the surface of silver nanowires can form a silica shell. Hydrogen sulfide treatment for 500 hours, the change in the square resistance of the conductive film is 0.3%; 30V DC voltage treatment for 500 hours, the change in the square resistance of the conductive film is 0.6%; 10% hydrochloric acid solution treatment for 1000 hours, the change in the square resistance of the conductive film is 0.6%; 10% hydrogen Sodium oxide solution treatment for 1000 hours, the change in square resistance of the conductive film is 0.5%; treatment at 300°C for 30 minutes, the change in square resistance of the conductive film is 4%.

Embodiment 3

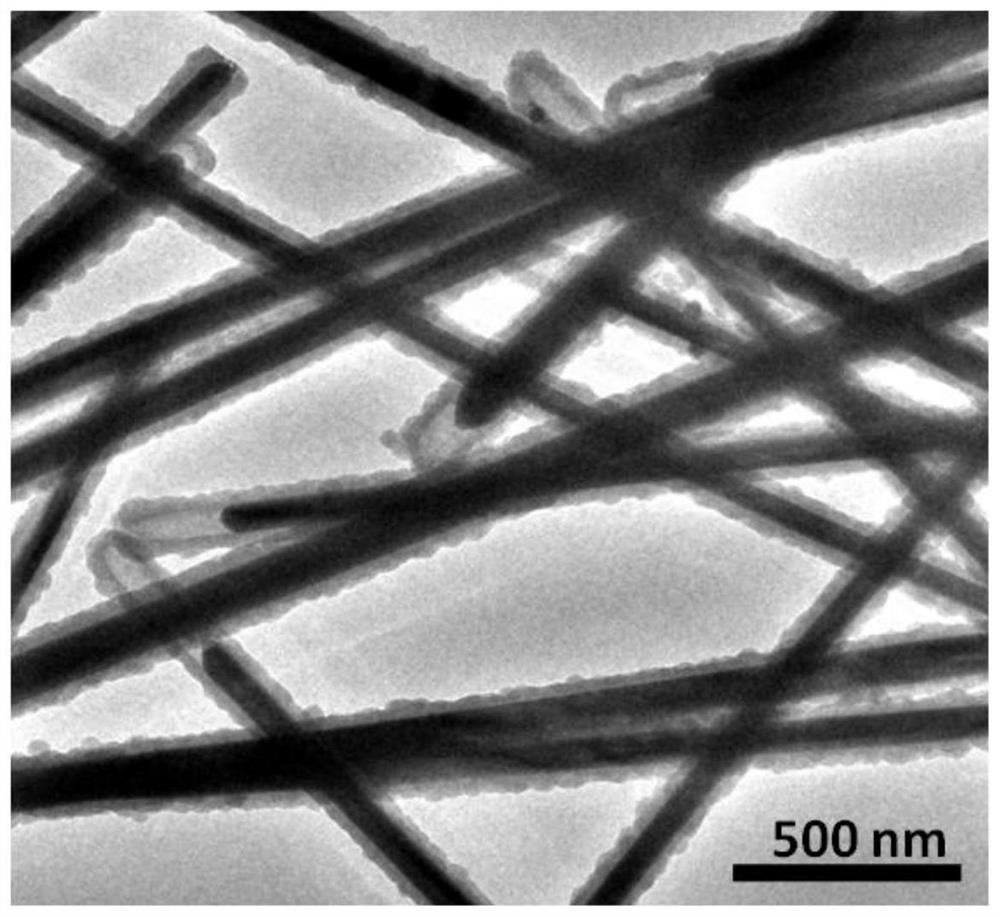

[0037] The silver nanowire transparent conductive film was prepared in the same manner as in Example 1 except that the pH of the sodium hydroxide aqueous solution was 8. Tested by transmission electron microscopy, such as image 3 As shown, the surface of silver nanowires can form a silica shell. Hydrogen sulfide treatment for 500 hours, the change in the square resistance of the conductive film is 0.1%; 30V DC voltage treatment for 500 hours, the change in the square resistance of the conductive film is 0.5%; 10% hydrochloric acid solution treatment for 1000 hours, the change in the square resistance of the conductive film is 0.5%; 10% hydrogen Sodium oxide solution treatment for 1000 hours, the change in square resistance of the conductive film is 0.8%; treatment at 300°C for 30 minutes, the change in square resistance of the conductive film is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com