Preparation method of low-resistivity garnet type modified LLZO solid electrolyte

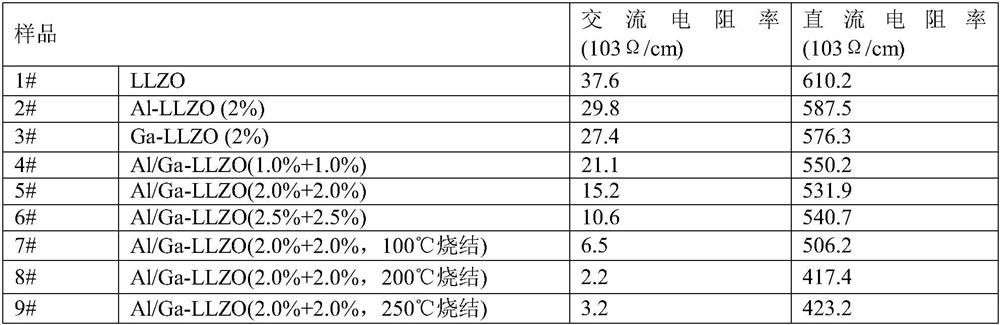

A solid electrolyte, garnet-type technology, applied in the direction of electrolytes, circuits, electrical components, etc., can solve the problems of large interface impedance, high operating costs, high material costs, etc., to improve the conductivity of grain boundaries, reduce DC and AC resistivity , Improve the effect of mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of low-resistivity garnet-type modified LLZO solid electrolyte, comprising the following steps:

[0026] 1) Preparation of Al / Ga doped modified LLZO solid electrolyte: Li 2 CO 3 (purity 99.9%, add 5-15% excess Li 2 CO 3 to compensate for Li loss during sintering), La 2 o 3 (purity 99.9%), ZrO 2 (purity 99.9%), Ga 2 o 3 (purity 99.9%), Al 2 o 3 (purity 99.9%) as raw material, according to the required stoichiometric ratio into the three-dimensional high-energy vibration ball mill (the total doping amount of Ga and Al in LLZO is not more than 5wt%), the inner wall of the ball mill is made of zirconia, and the grinding balls are steel balls , tungsten carbide ball, polyaminopeptide ball, the ratio of ball to material is 20-50:40-80, ball milling at room temperature for 5-10 minutes, and sintering in air at 300-400°C for 1-3 hours to promote different Interfacial compatibility between raw materials, cooling to room temperature at a rate of 10...

Embodiment 1

[0029] Preparation of Al / Ga-doped modified LLZO solid electrolyte: Li 2 CO 3 (purity 99.9%, add 10% excess Li 2 CO 3 to compensate for Li loss during sintering), La2 o 3 (purity 99.9%), ZrO 2 (purity 99.9%), as a raw material, according to the required stoichiometric ratio into the three-dimensional high-energy vibration ball mill, the inner wall of the ball mill is made of zirconia, the grinding balls are tungsten carbide balls, the ball-material ratio is 25:45, ball milling at room temperature for 10 minutes, Sinter in air at 400°C for 3 hours to promote interfacial compatibility between different raw materials, cool to room temperature at a rate of 10°C / min, continue ball milling and mixing for 10 minutes, and sinter anaerobically at 1000°C for 8 hours at 400Mpa to increase crystallization Degree and density, LLZO solid electrolyte was prepared, with an average particle size of 0.5-1.0 μm.

Embodiment 2

[0031] The difference from Example 1 is: 2% Al doping is carried out, and the Al-containing raw material is Al 2 o 3 (purity 99.9%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com