Adjustable high-optical-efficiency broadband multi-longitudinal-mode Raman microchip laser

An optical efficiency, Raman microchip technology, applied in lasers, laser parts, structures/shapes of optical resonators, etc., can solve problems such as difficulty in achieving high optical efficiency output, limiting output power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

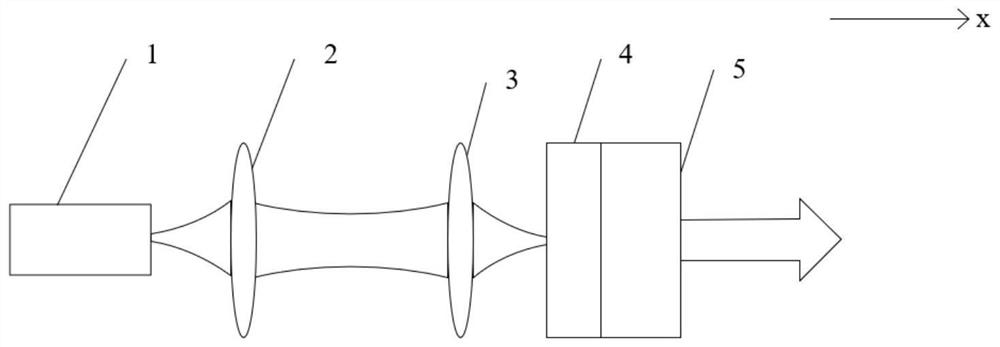

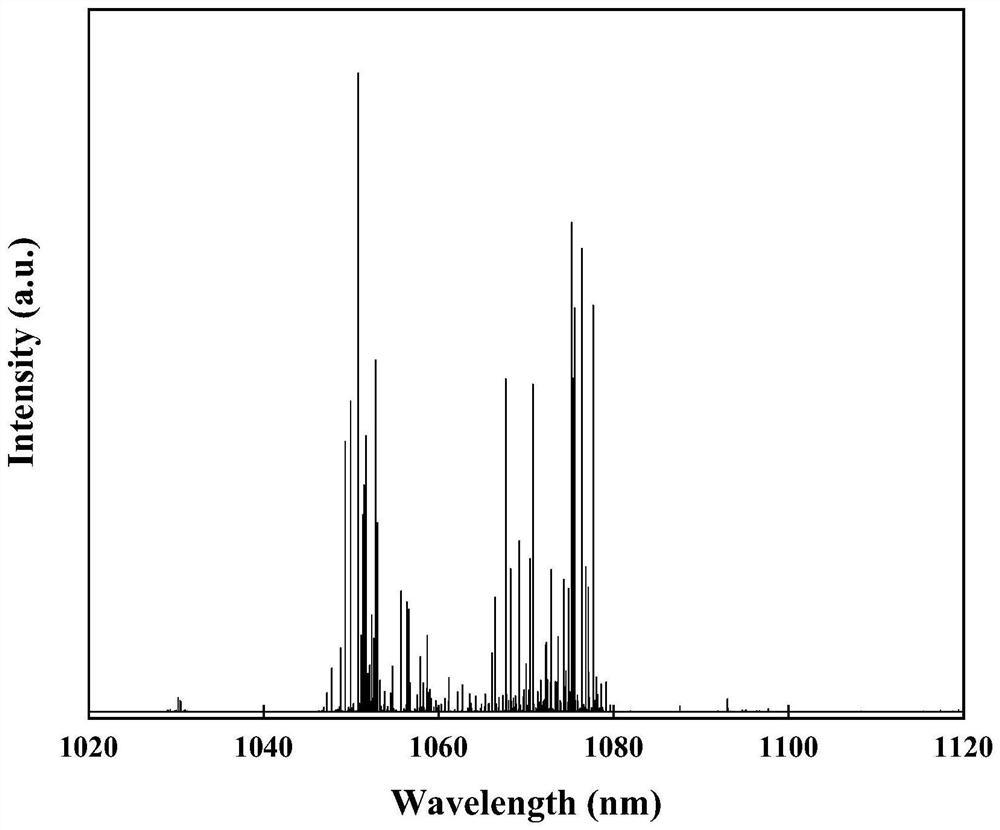

[0069] combine figure 1 As shown, in the present embodiment, the laser crystal 4 selects 1 mm thick 20at% doped Yb:YAG crystal; the Raman crystal 5 selects a-cut YVO with a thickness of 1.5 mm 4 crystals.

[0070] The side of the laser crystal 4 facing the focusing lens 3 is coated with an anti-reflection film for 940nm pump light and a high-reflection film for wavelength 1030-1100nm, which serves as an incident cavity mirror of the laser resonator. The side of the Raman crystal 5 facing the laser crystal 4 is coated with an anti-reflection film for 1030-1100 nm, and the other side is coated with a high-reflection film for 1030-1100 nm, which serves as the output cavity mirror of the laser resonator. The reflectivity of the reflective film to 1030-1100nm laser is greater than 99.5%.

[0071] The pump source 1 is a fiber-coupled quasi-continuous light-emitting diode with a center wavelength of 940nm, the fiber core diameter is 200 μm, the numerical aperture (NA) is 0.22, the ...

Embodiment 2

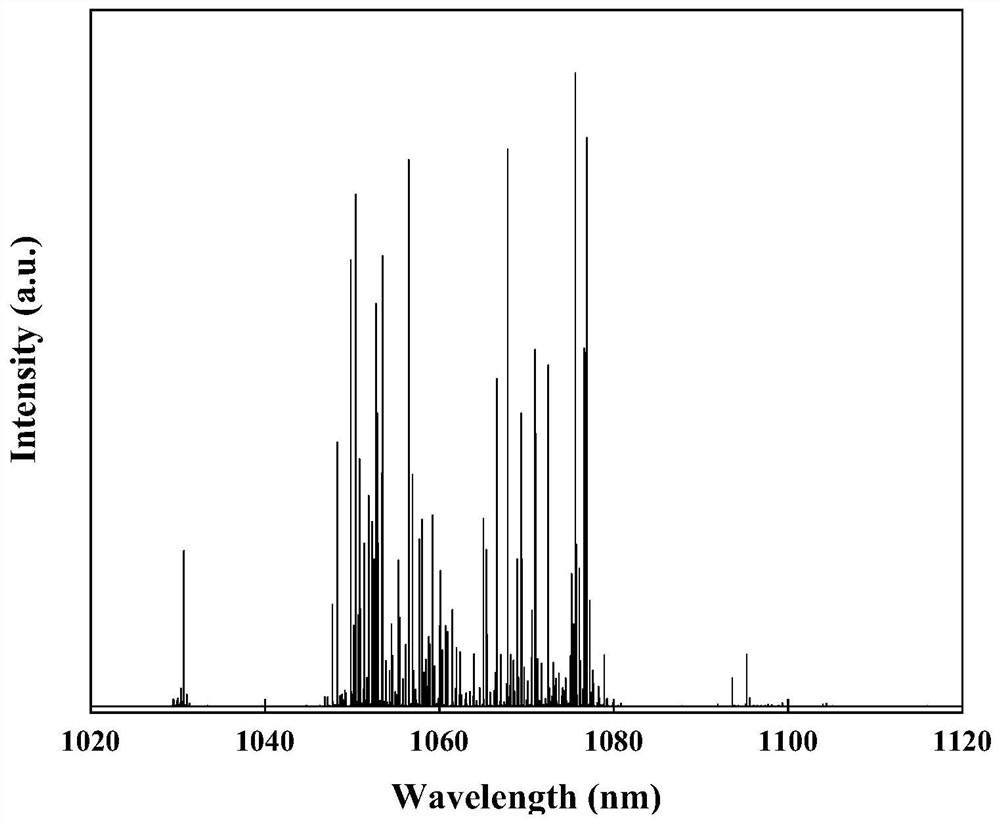

[0085] combine figure 1As shown, this embodiment is roughly the same as Embodiment 1, and the difference between this embodiment and Embodiment 1 is that this embodiment replaces the Raman crystal 5 with a thickness of 2mm a-cut YVO 4 crystals. The pumping source 1, the collimating lens 2, the focusing lens 3, the laser crystal 4, the optical path and the experimental method are all the same as those in the first embodiment.

[0086] This embodiment generates 1110nm second-order Raman light on the basis of Embodiment 1, expanding the spectral range of the output laser.

[0087] When Δx=100mm, the radius of the pumping spot shaped by the collimating lens and the focusing lens is 97 μm. As the pump power increases, both the longitudinal mode number and the spectral width of the output laser increase. At pump power P in =35.6W, the obtained broadband multi-longitudinal mode laser spectrum is as follows Figure 5 shown. In the laser spectrum, the 1050nm fundamental frequency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com