Green preparation method of food-grade multifunctional lignin/silicon dioxide nanoparticle emulsifier

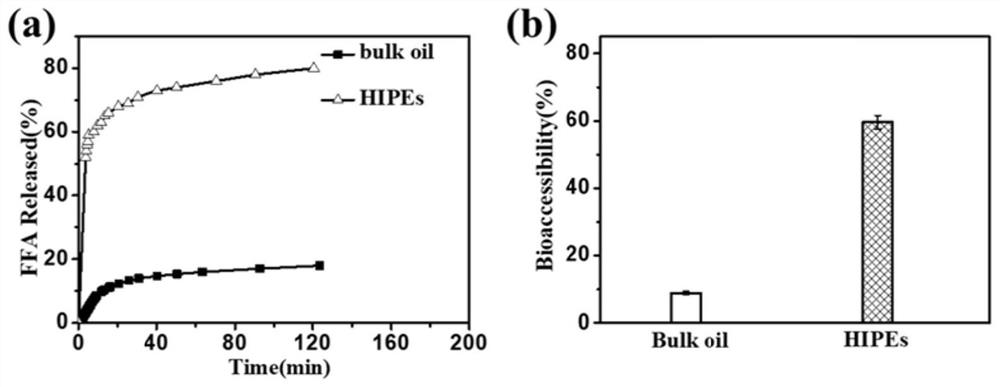

A nanoparticle, silicon dioxide technology, used in food ingredients as emulsifiers, food ingredients, cosmetic preparations, etc., can solve the problems of easy deterioration of active substances, toxic changes, lack of UV oxidation protection performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

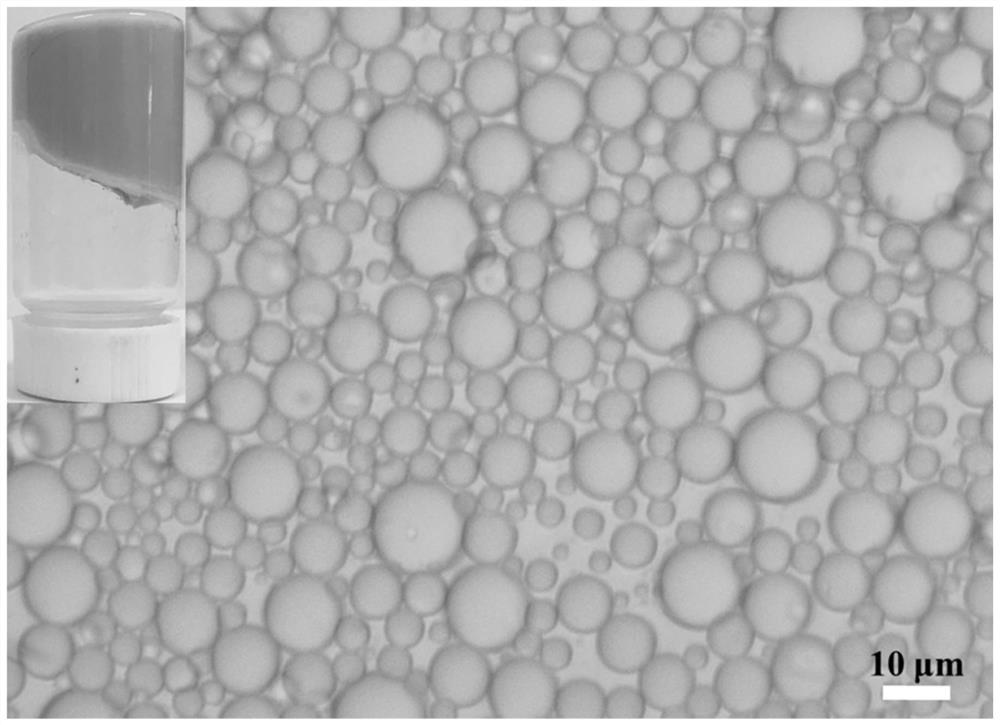

Image

Examples

Embodiment 1

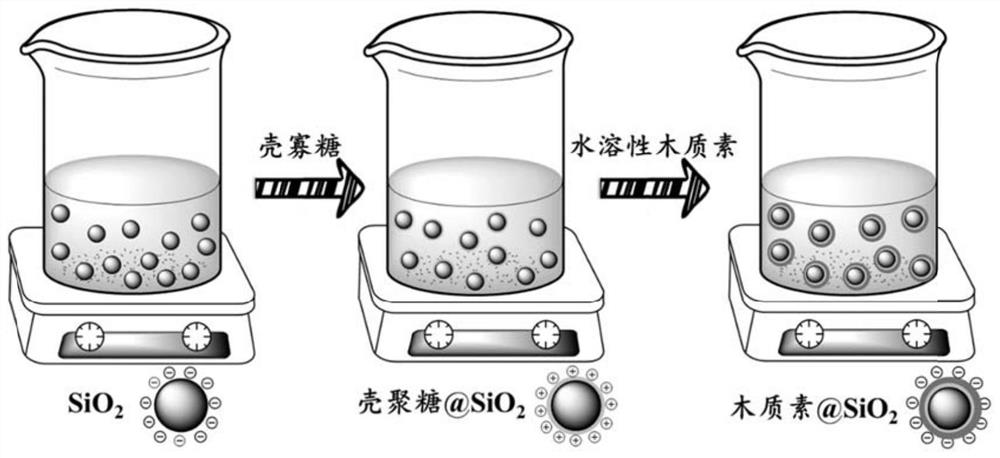

[0030] Dissolve 4.0 g of enzymatic lignin in 20 mL of 1 mol / L sodium hydroxide aqueous solution, and centrifuge to remove incompatible impurities. Then, adjust the pH to neutral with 0.1 mol / L hydrochloric acid solution, centrifuge again to remove water-insoluble lignin, dialyze, freeze-dry and set aside. Weigh 2.0g SiO2 2 Nanoparticles were dispersed in 10mL pure water, 1mL 5g / mL chitosan solution was added, after stirring for 10min, the supernatant was removed by centrifugation, and the remaining solid was washed twice with ultrapure water. Subsequently, the above-mentioned particles were dispersed in pure water again, 0.5 g of the above-mentioned water-soluble lignin was added, and after stirring for 10 minutes, the supernatant was removed by centrifugation, and the remaining solid was washed twice with ultra-pure water, and the final sample was freeze-dried to obtain the Grade multifunctional lignin / silica nanoparticles.

Embodiment 2

[0032] Dissolve 4.0 g of enzymatic lignin in 20 mL of 1 mol / L sodium hydroxide aqueous solution, and centrifuge to remove incompatible impurities. Then, adjust the pH to neutral with 0.1 mol / L hydrochloric acid solution, centrifuge again to remove water-insoluble lignin, dialyze, freeze-dry and set aside. Weigh 4.0g SiO2 2 Nanoparticles were dispersed in 10mL pure water, 1mL 5g / mL chitosan solution was added, after stirring for 10min, the supernatant was removed by centrifugation, and the remaining solid was washed twice with ultrapure water. Subsequently, the above-mentioned particles were dispersed in pure water again, 0.5 g of the above-mentioned water-soluble lignin was added, and after stirring for 10 minutes, the supernatant was removed by centrifugation, and the remaining solid was washed twice with ultra-pure water, and the final sample was freeze-dried to obtain the Grade multifunctional lignin / silica nanoparticles.

Embodiment example 3

[0034] Dissolve 4.0 g of enzymatic lignin in 20 mL of 1 mol / L sodium hydroxide aqueous solution, and centrifuge to remove incompatible impurities. Then, adjust the pH to neutral with 0.1 mol / L hydrochloric acid solution, centrifuge again to remove water-insoluble lignin, dialyze, freeze-dry and set aside. Weigh 6.0g SiO2 2 Nanoparticles were dispersed in 10mL pure water, 1mL 5g / mL chitosan solution was added, after stirring for 10min, the supernatant was removed by centrifugation, and the remaining solid was washed twice with ultrapure water. Subsequently, the above-mentioned particles were dispersed in pure water again, 0.5 g of the above-mentioned water-soluble lignin was added, and after stirring for 10 minutes, the supernatant was removed by centrifugation, and the remaining solid was washed twice with ultra-pure water, and the final sample was freeze-dried to obtain the Grade multifunctional lignin / silica nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com