Method for improving water solubility of astaxanthin and protecting astaxanthin from oxidative degradation of Fe<2+>

A technology for oxidative degradation and astaxanthin, applied in skin care preparations, non-active ingredients of polymer compounds, cosmetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of astaxanthin-astaxanthin complex, comprising the steps of:

[0029] a) Prepare an astaxanthin solution with a concentration of 0.25-3.0 mmol / L, that is, weigh 0.0036 g of astaxanthin and dissolve it in 2.0 mL-24.0 mL of dimethyl sulfoxide / ethanol / acetone;

[0030] b) separating and purifying the shrimp ferritin, and preparing a shrimp ferritin solution with a concentration of 0.5-20 μmol / L.

[0031]c) Slowly stir the shrimp ferritin solution prepared in step b, then slowly drop the astaxanthin solution prepared in step a into the shrimp ferritin solution, the molar ratio of shrimp ferritin to green pigment is 1:10~1: 200;

[0032] d) Slowly stirring and reacting, the reaction time is 0.5 to 2 hours, and the reaction temperature is 15°C to 35°C to obtain an astaxanthin-prastoferrin complex solution;

[0033] An astaxanthin-astaxanthin complex prepared according to the preparation method, the final combination ratio of astaxanthin and astaxanthin ...

Embodiment

[0039] Preparation of Astaxanthin-Astaxanthin Complex:

[0040] a) preparing an astaxanthin solution with a concentration of 1.0 mmol / L, and dissolving it in dimethyl sulfoxide;

[0041] b) separating and purifying shrimp ferritin, and preparing a shrimp ferritin solution with a concentration of 1.0 μmol / L;

[0042] c) Slowly stir the shrimp ferritin solution prepared in step b, then slowly add the astaxanthin solution prepared in step a into the shrimp ferritin solution, 2 μL each time, drop 10 times, the astaxanthin and astaxanthin solution The molar ratio is 1:20;

[0043] d) Slowly stirring and reacting, the reaction time is 0.5h, and the reaction temperature is 20°C to obtain an astaxanthin-astiferrin complex solution;

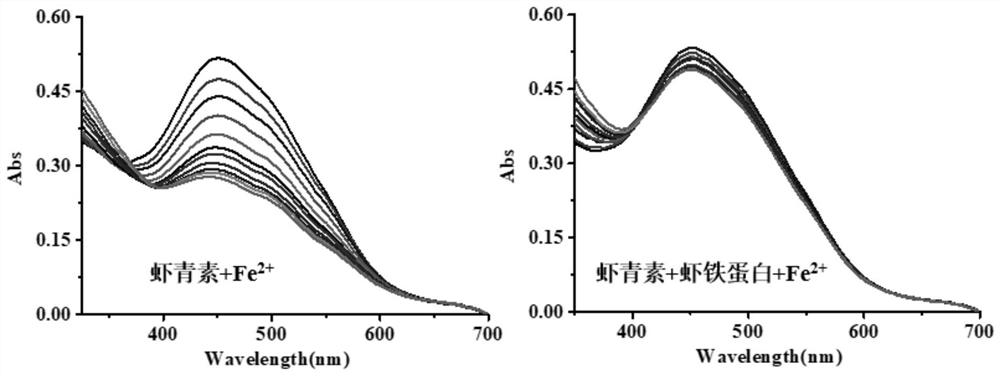

[0044] Detection of Astaxanthin-Astaxanthin Complexes of the Invention from Fe 2+ Ability to induce oxidative degradation.

[0045] The Fe 2+ Induced astaxanthin oxidative damage. First, dilute astaxanthin (1.0mmol / L, 10μL) into 1.0mL MOPS buffer or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com