Zero-valent iron agent modified by aromatic carboxylic acid, and preparation method and application thereof

A kind of aromatic carboxylic acid, zero-valent iron technology, applied in the field of environmental chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of micron zero-valent iron is as follows: (1) zirconia ball milling beads (6 mm in particle diameter) with 20% cavity volume are packed into a ball mill jar as a grinding medium; (2) 2.365 g of zero-valent iron powder (38 mm in particle diameter) Micron ~ 74 micron) placed in the ball mill tank, and filled with nitrogen in the tank; (3) Turn on the ball mill, adjust the grinding speed to 400rpm, and grind for 20 hours; (4) Under nitrogen atmosphere, use a screen to filter the prepared Micron zero-valent iron is separated from the grinding medium to obtain micron zero-valent iron.

[0062] The preparation method of nano zero-valent iron is as follows: take 110mL ultrapure aqueous solution and 0.7447g ferrous sulfate heptahydrate into a 250mL three-necked flask, add 40ml of 0.13M NaBH4 solution dropwise at a flow rate of 6ml / min, and perform a reduction reaction to synthesize nano The zero-valent iron solution is centrifuged and dried to obtain nano...

Embodiment 1

[0067] Take 110mL of 10mM phthalic acid solution and 0.7447g of ferrous sulfate heptahydrate in a 250mL three-neck flask, add 40ml of 0.13M NaBH dropwise at a flow rate of 6ml / min 4 Solution, carry out reduction reaction, to synthesize nano zero valent iron solution (nZVI solution); after 15min, add 2.14mL of Na 2 The S solution (8g / L) was mixed and reacted for 15 minutes; the whole process was mechanically stirred under anaerobic conditions, and finally a phthalic acid-modified sulfide nanometer zero-valent iron solution was obtained. After magnetic absorption and drying, aromatic carboxylic acid-modified solid sulfide nanometer zero-valent iron was obtained for characterization.

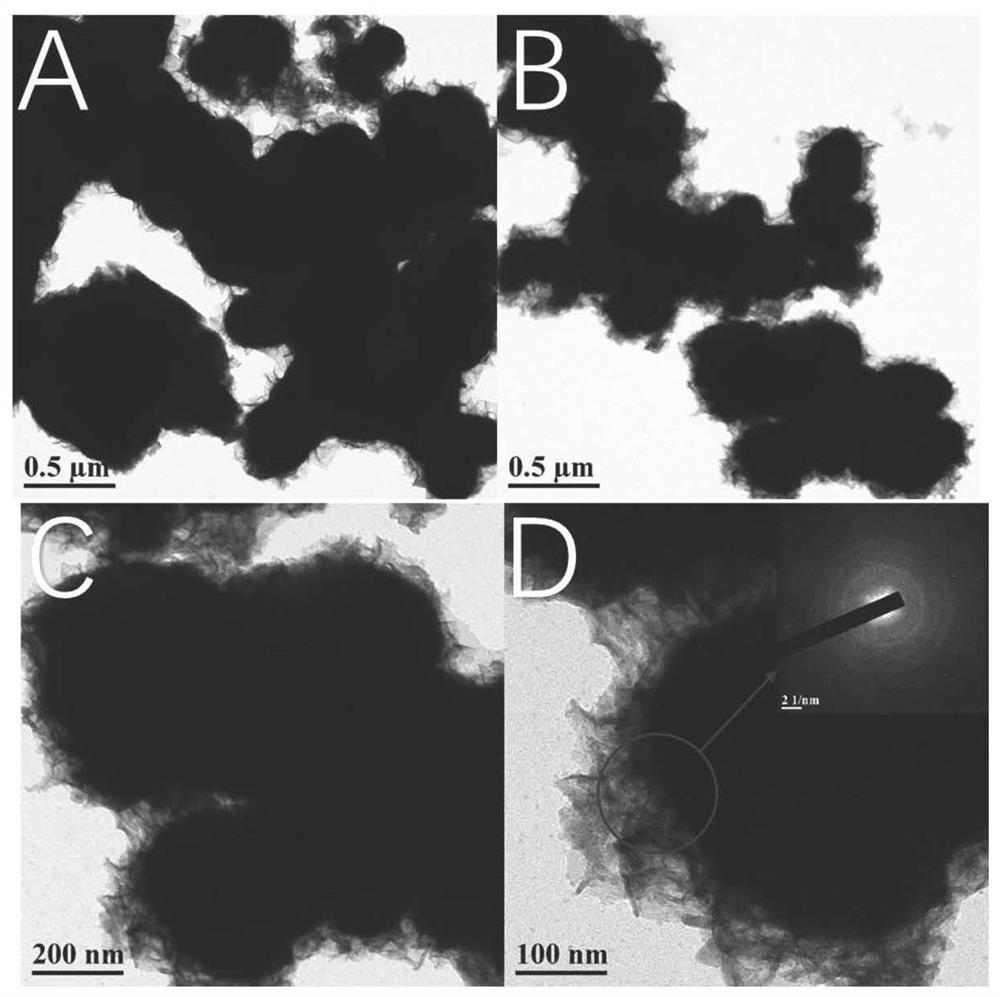

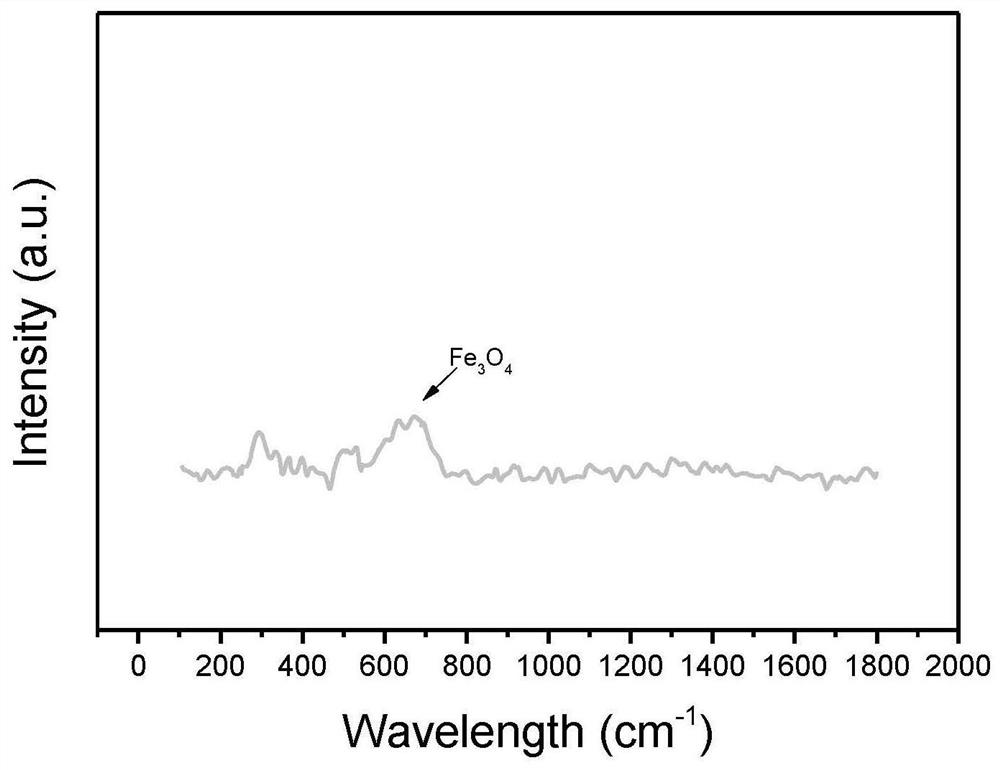

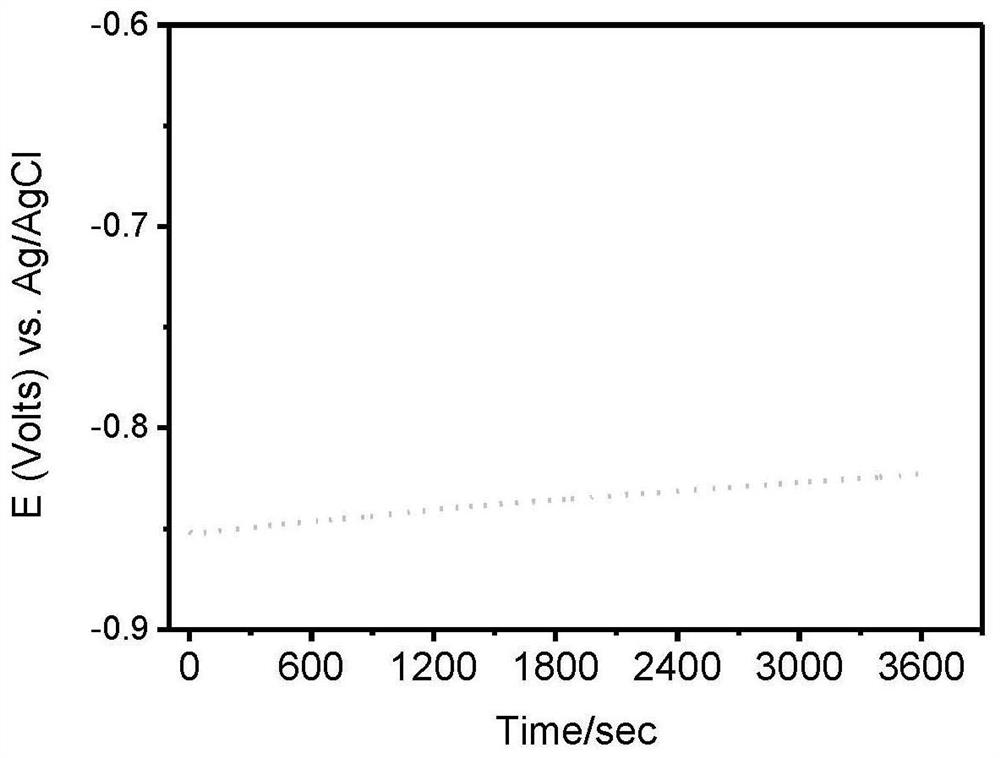

[0068] Table 1 and Figure 1~4 The following are the element mass analysis table, TEM diagram, Raman diagram, CP diagram and XPS diagram of the sulfide nano-zero-valent iron prepared in this embodiment in sequence. It can be calculated from Table 1 that the sulfur loading is close to 80% of the i...

Embodiment 2

[0072] Take 110mL of 10mM benzoic acid solution and 0.7447g of ferrous sulfate heptahydrate in a 250mL three-necked flask, add 40ml of 0.13M NaBH dropwise at a flow rate of 6ml / min 4 Solution, carry out reduction reaction to synthesize nZVI solution; add 2.14mL of Na after 15min 2 S solution (8g / L) was vulcanized for 15 minutes; the whole process was mechanically stirred under anaerobic conditions to obtain a benzoic acid-modified sulfidized nanometer zero-valent iron solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com