Polyacid-polyaniline-glycerol-polyvinyl alcohol composite gel and preparation method thereof

A polyvinyl alcohol and composite gel technology, applied in the field of conductive polymers, can solve the problems of low sensitivity, poor conductivity of conductive gel, slow response, etc., achieve broad application prospects, enhance dispersion performance, and improve the effect of antifreeze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

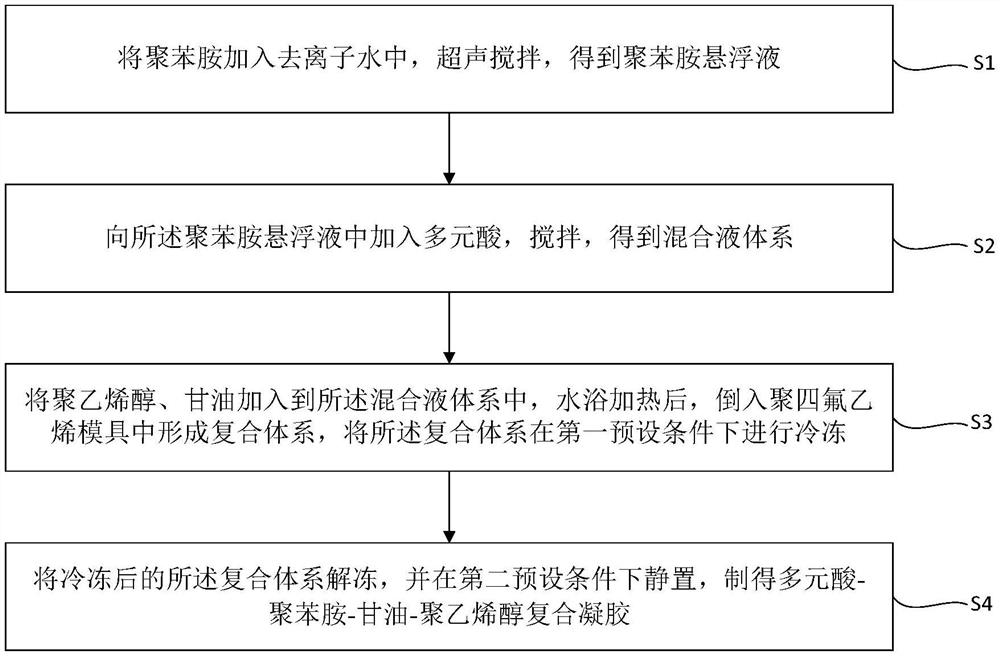

[0028] combine figure 1 As shown, the embodiment of the present invention provides a preparation method of polybasic acid-polyaniline-glycerin-polyvinyl alcohol composite gel, comprising the following steps:

[0029] S1. Add polyaniline to deionized water, and uniformly disperse it into a nano-sized polyaniline suspension under the action of ultrasound;

[0030] S2, adding polybasic acid to the polyaniline suspension, stirring to obtain a mixed liquid system;

[0031] S3. Add polyvinyl alcohol and glycerin to the mixed liquid system, heat it in a water bath, pour it into a polytetrafluoroethylene mold to form a composite system, and freeze the composite system under the first preset condition;

[0032] S4. Thaw the frozen composite system, and let it stand under the second preset condition to prepare polyacid-polyaniline-glycerol-polyvinyl alcohol composite gel.

[0033] It is understandable that polyvinyl alcohol (PVA), as a material, is widely used in the process of prepar...

Embodiment 1

[0046] This embodiment provides a preparation method of polybasic acid-polyaniline-glycerin-polyvinyl alcohol composite gel, which specifically includes the following steps:

[0047] 1) Add polyaniline to deionized water, stir and sonicate to obtain a suspension with a concentration of 5 mg / mL;

[0048] 2) Add 25 mg of tannic acid to the suspension, and stir for 8 hours to obtain a mixed liquid system;

[0049] 3) Add 1.5g of polyvinyl alcohol powder and 5mL of glycerin to the mixed liquid system, and after heating in a water bath at 95°C, pour it into a polytetrafluoroethylene mold and store it at minus 30°C for 8 hours.

[0050] 4) The frozen composite system was thawed at room temperature, and placed at 4°C for 6 hours after thawing to obtain a polyacid-polyaniline-glycerol-polyvinyl alcohol composite gel.

[0051] The polybasic acid-polyaniline-glycerin-polyvinyl alcohol composite gel prepared in the present embodiment 1 is subjected to a tensile test, and the test condit...

Embodiment 2

[0055] This embodiment provides a preparation method of polybasic acid-polyaniline-glycerin-polyvinyl alcohol composite gel, the difference from Example 1 is:

[0056] In step 1), polyaniline is added to deionized water, stirred and ultrasonicated to obtain a suspension with a concentration of 10 mg / mL;

[0057] All the other steps and parameters are the same as in Example 1.

[0058] The polybasic acid-polyaniline-glycerin-polyvinyl alcohol composite gel that embodiment 2 makes is carried out tensile test, and test condition is: under room temperature environment, with the universal testing machine that 1kN load cell is housed, sample size during test is 2mm×6mm×30mm, the moving speed of the mold is set to 50mm / min.

[0059] As shown in Table 1, the polybasic acid-polyaniline-glycerol-polyvinyl alcohol composite gel obtained in Example 2 has resistance change rates of 90%, 50%, and 75% when stretched to the original length of 25%, 50%, and 75%, respectively. 160%, 260%, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com