Deep denitrification system device and denitrification process for high-ammonia-nitrogen wastewater

A deep denitrification and system device technology, which is applied in animal husbandry wastewater treatment, aerobic and anaerobic process treatment, water pollutants, etc., can solve problems such as incomplete oxidative denitrification, unsatisfactory denitrification, and weak adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

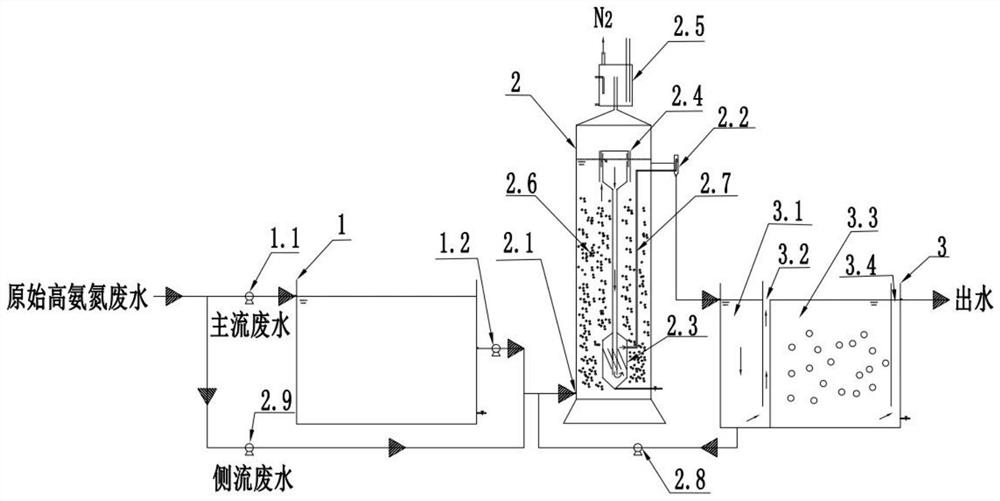

[0038] The processing of embodiment 1 livestock and poultry farm excrement and urine

[0039] (1) The original high-ammonia-nitrogen wastewater is divided into mainstream wastewater and side-stream wastewater, and the flow ratio of the two is 2.5;

[0040] (2) The mainstream wastewater enters the short-range nitrification reactor 1 through the mainstream wastewater inlet pump 1.1 for short-range nitrification reaction. In the short-range nitrification reactor, non-accurate continuous timing aeration is adopted, and the hydraulic retention time is controlled for 6 hours. The produced nitrate nitrogen and nitrous The nitrogenous wastewater is discharged through the outlet pump 1.2, and forms mixed wastewater with the side stream wastewater and the incoming water of the circulating water inlet area 3.1, and enters the high-efficiency denitrification anaerobic reactor 2 through the water inlet 2.1. The denitrifying bacteria in the liquid phase in the interior use the organic matte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com