Duplex oxidation ditch sewage treatment method

A sewage treatment method and oxidation ditch technology, applied in flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. issues such as miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

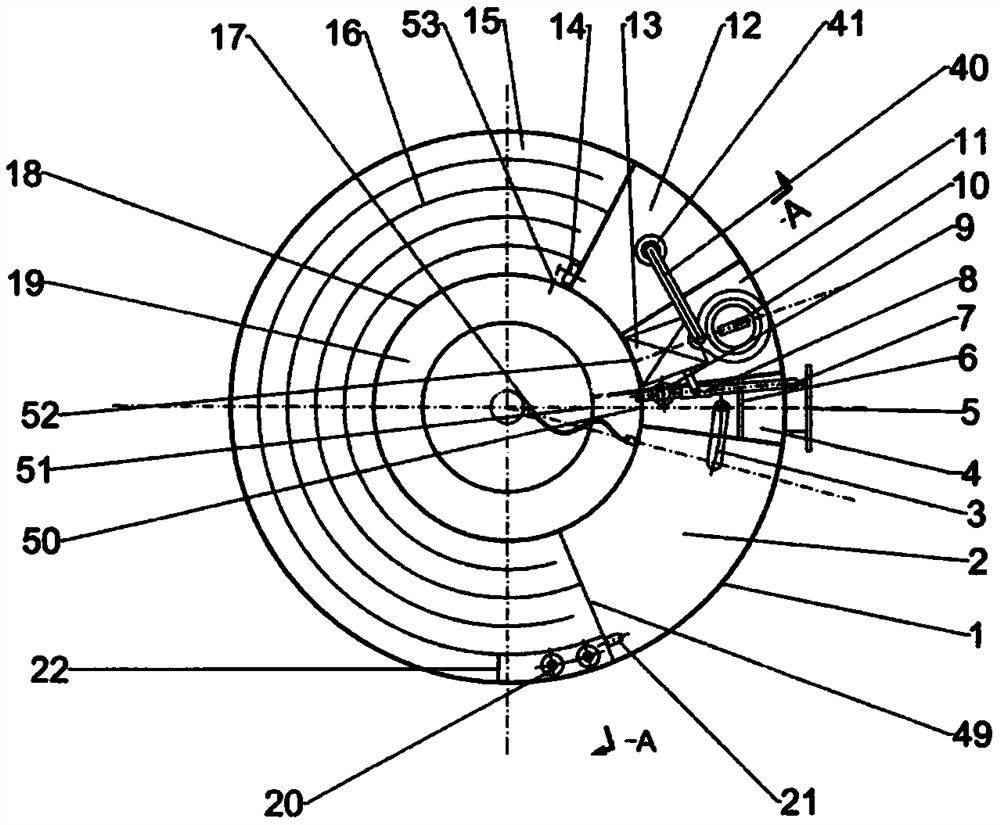

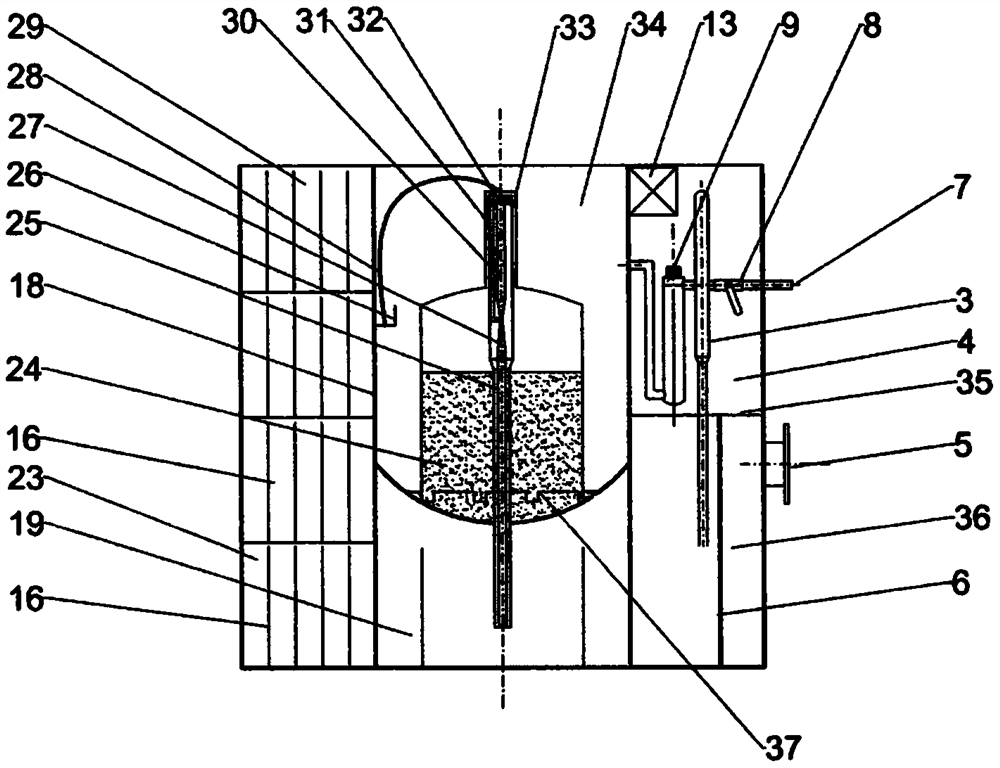

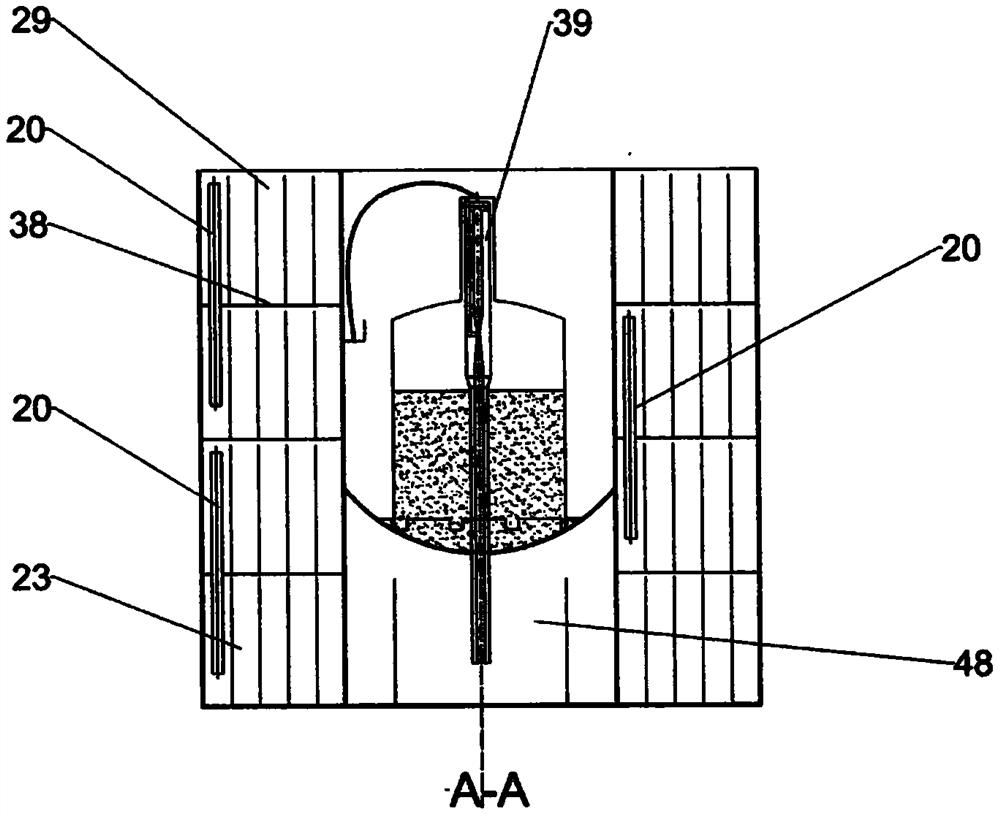

[0047] as attached figure 1 , 2 , The embodiment shown in 3, 4 and 5 is an integrated sewage treatment unit with a trapezoidal oxidation ditch method with a filter tank. It includes grid tank 4, anaerobic zone 48, upper and lower multi-layer reaction tanks 15, secondary settling tank 2, filter tank 24, reverse selection water storage tank 34, ultraviolet sterilizer 9 and other main water treatment process units; Lower multi-layer reaction tank 15 comprises top layer reaction tank 29, bottom layer reaction tank 23 and middle layer reaction tank (total 4 layers in the present embodiment), and every layer of reaction tank is connected end to end by a plurality of semicircular reaction tanks, each reaction tank The aspect ratio is relatively large, forming a ditch form. The end of the top floor reaction tank 29 is connected to the first end of the second reaction tank through the communication pipe 20, and so on until the head end of the bottom reaction tank 23; 1. The aeration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com