Double-chain polyethylene oxide modified covalent organic framework as well as preparation method and application thereof

A technology of covalent organic framework and polyethylene oxide, which is applied in the preparation, covalent organic framework modified by double-chain polyethylene oxide, and the application field of ion conduction, which can solve the problem that the conductivity is not particularly ideal and there is no ion Conductive performance application research and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Double-chain polyethylene oxide-modified covalent organic framework (COF-PEO-1,1), which is composed of 1,3,5-tris(4-formylphenyl)benzene and PEG-1,1-NHNH 2 The organic framework formed by the Schiff base reaction has the following structure:

[0049]

[0050] PEG-1,1-NHNH 2 The structure of the is as follows:

[0051]

[0052] The preparation method of COF-PEO-1,1, the specific steps are as follows;

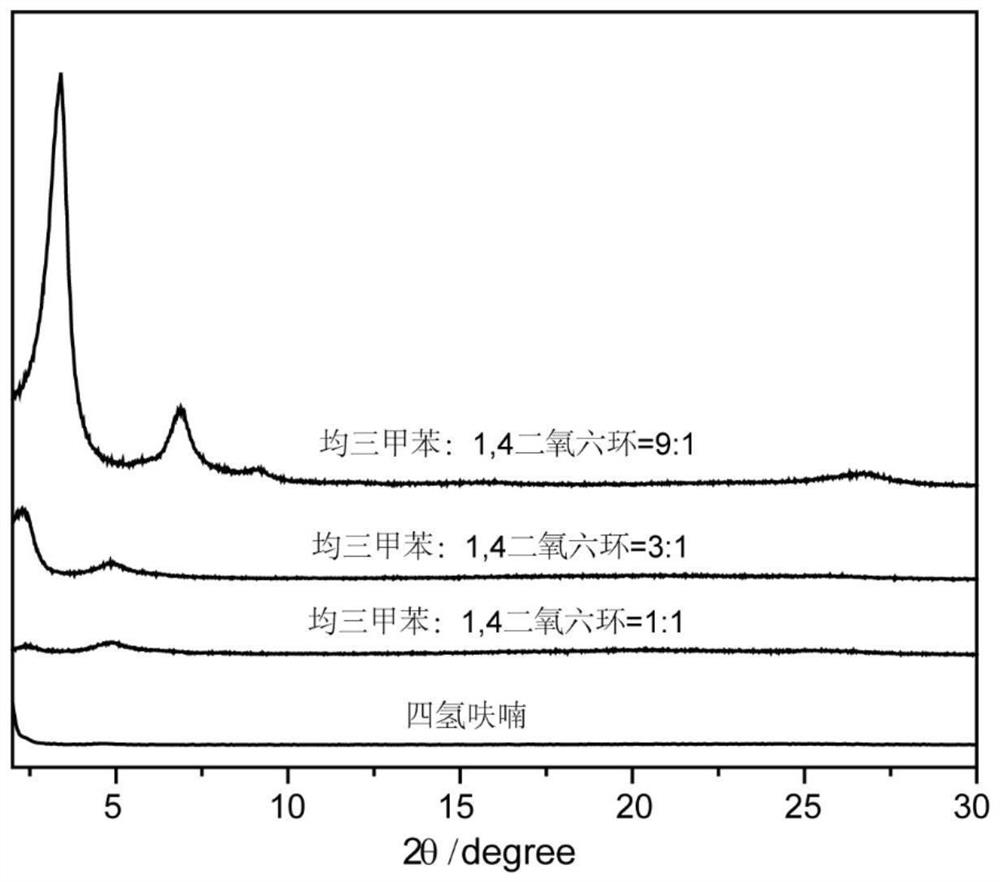

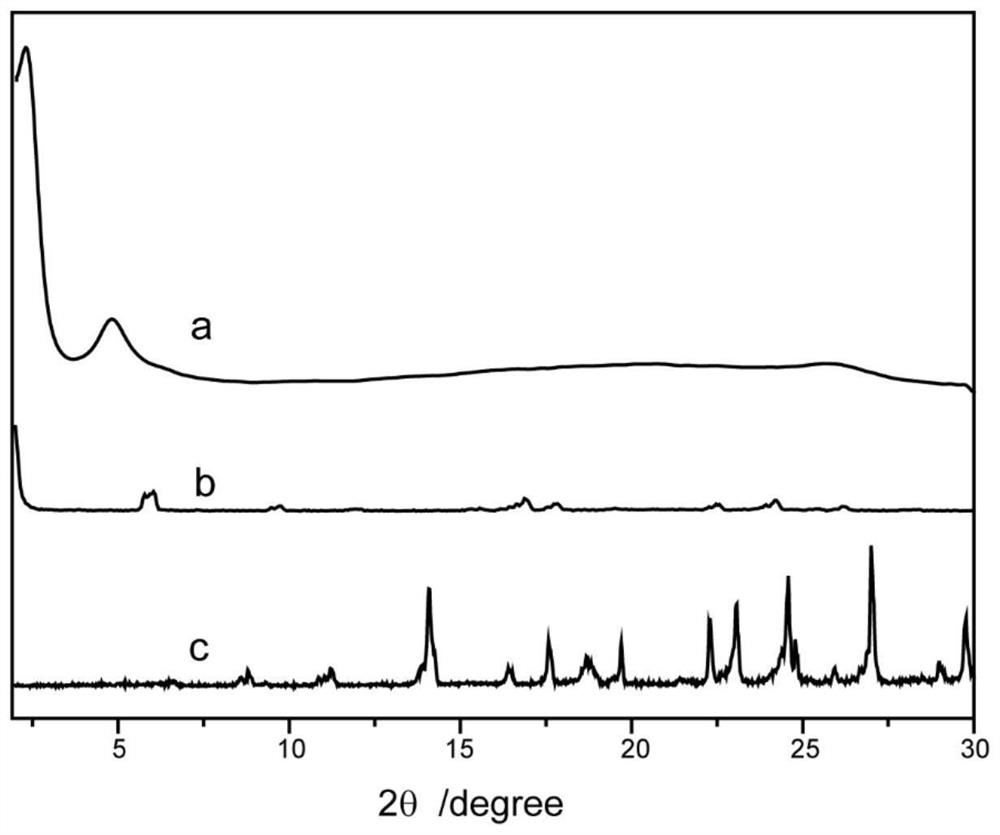

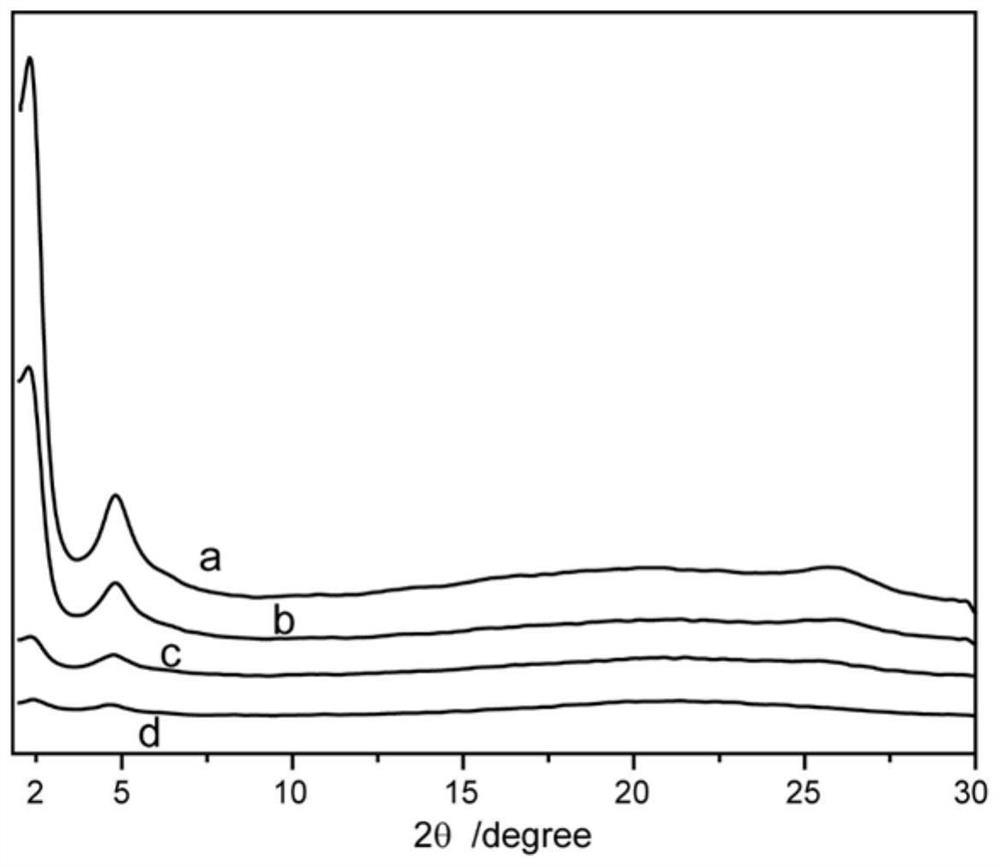

[0053] Take 0.05mmol 1,3,5-tris(4-formylphenyl)benzene, 0.075mmol PEG-1,1-NHNH 2 , add 1.8ml of mesitylene and 0.2ml of 1,4-dioxane, ultrasonically disperse the raw materials to form a suspension, add 0.2ml of 6mol / L acetic acid solution, continue to ultrasonically disperse into a suspension, and the suspension Freezing with liquid nitrogen, vacuuming, and degassing three times in sequence. Under the state of vacuuming, use a flame gun to seal the tube, and then put it in a 120°C oven for 72 hours of reaction; after taking it out and cooling, the crude product is...

Embodiment 2

[0063] This example is basically the same as Example 1, the only difference is that the monomer is PEG-2,2-NHNH 2 ,Specifically:

[0064] Take 0.05mmol1,3,5-tris(4-formylphenyl)benzene, 0.075mmol PEG-2,2-NHNH 2 , add 1.8ml of mesitylene and 0.2ml of 1,4-dioxane, ultrasonically disperse the raw materials to form a suspension, add 0.2ml of 6mol / L acetic acid solution, continue to ultrasonically disperse into a suspension, and the suspension Freezing with liquid nitrogen, vacuuming, and degassing three times in sequence. Under the state of vacuuming, use a flame gun to seal the tube, and then put it in a 120°C oven for 72 hours of reaction; after taking it out and cooling, the crude product is obtained, and the crude product is used in turn. Dichloromethane, ethyl acetate, methanol, acetone washed and suction filtered three times, then extracted with tetrahydrofuran and trichloromethane Soxhlet for three days, put into a vacuum drying oven at 50°C and dried for 12 hours to obtai...

Embodiment 3

[0066] This example is basically the same as Example 1, the only difference is that the monomer is PEG-3,3-NHNH 2 ,Specifically:

[0067] Take 0.05mmol 1,3,5-tris(4-formylphenyl)benzene, 0.075mmol PEG-3,3-NHNH 2 , add 1.8ml of mesitylene and 0.2ml of 1,4-dioxane, ultrasonically disperse the raw materials to form a suspension, add 0.2ml of 6mol / L acetic acid solution, continue to ultrasonically disperse into a suspension, and the suspension Freezing with liquid nitrogen, vacuuming, and degassing three times in sequence. Under the state of vacuuming, use a flame gun to seal the tube, and then put it in a 120°C oven for 72 hours of reaction; after taking it out and cooling, the crude product is obtained, and the crude product is used in turn. Dichloromethane, ethyl acetate, methanol, and acetone were washed and suction filtered three times, then extracted with tetrahydrofuran and trichloromethane for three days by Soxhlet, and dried in a vacuum oven at 50°C for 12 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com